An aggregate of iron particles with a size of less than 1 mm. Colour: Black. It is the main raw material of powder metallurgy. According to the particle size, it is customarily divided into five grades: coarse powder, medium powder, fine powder, fine powder and superfine powder. Iron powder composed of particles with a particle size ranging from 150 to 500 μm is coarse powder, with a particle size of 44 to 150 μm for medium powder, 10 to 44 μm for fine powder, 0.5 to 10 μm for extremely fine powder, and less than 0.5 μm for ultrafine powder pink. Generally, the powder that can pass through the 325 mesh standard sieve, that is, the particle size is less than 44μm, is called sub-sieve powder. For higher-precision sieving, you can only use airflow classification equipment, but for some easily oxidized iron powder, you can only use JZDF. Nitrogen protection classifier to do it. Iron powder mainly includes reduced iron powder, atomized iron powder, and cast pig iron powder; they are named after different production methods.

Processing materials: iron powder (reduced iron powder, carbonyl iron powder, pure iron powder, sponge iron, high-carbon iron chromium powder, iron oxide powder)

Output: 100KG~200T/hour

Screening mesh number: 40~400 mesh

An important metal powder in the powder metallurgy industry. Iron powder is used in large amounts in powder metallurgy production, and its consumption accounts for about 85% of the total consumption of metal powder. The main market for iron powder is the manufacture of mechanical parts, and the amount of iron powder required accounts for about 80% of the total output of iron powder.

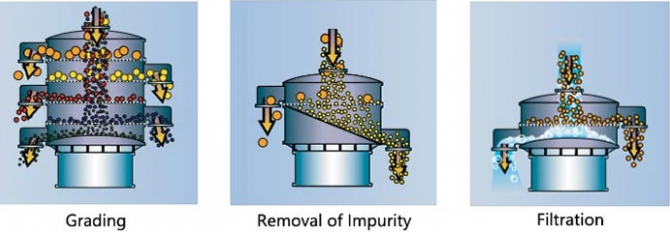

Generally, the vibratory sifter can be used for coarse screening, but for high-precision classification, an ultrasonic vibrating screen is required. For the classification of iron powders that are easy to oxidize and explode, only nitrogen protection classifier + air-tight ultrasonic vibrating screen can be used for high-precision Grading.

Compared with traditional screening solutions, vibratory sifter for iron powders can continuously screen high-quality electrolytic iron powder with twice the throughput while minimizing product waste.

Dahan Machinery is a manufacturer of screening and filtration technology. It has more than 12 years of experience in providing services to many processing industries such as metal powder, food, pharmaceuticals, chemicals, paints and coatings. To discuss your specific requirements with experienced sales engineers, please contact Dahan Machinery immediately.

Iron powder vibrating screen usually consists of the following main components:

Vibrator: The vibrator is the driving component of the vibrating screen, which generates vibration force to make the entire vibrating screen vibrate.

Screen: The screen is a mesh structure covering the screen body, and different sizes of screen holes are used as needed.

Bracket and base: The bracket and base are used to support and fix the various components of the vibrating screen to ensure the stable operation of the vibrating screen.

The vibration force generated by the vibrator is transmitted to the vibrating screen, causing the screen body to vibrate. According to the particle size of the iron powder, smaller powder can fall into the collection container below through the sieve hole, and larger particles are blocked by the sieve hole and cannot pass through, and will eventually be discharged from another coarse material port, so that the iron powder can be screened and graded.

Adding plates: Key features of the iron sifter

Robust, low-maintenance and designed for continuous operation

Easy to clean (CIP compatible)

Replaceable without tools

Due to the special combination of vibration, vibration frequency and stroke length, the sifter can handle the product extremely gently, minimizing damage and losses.

Operating conditions: -20 to +55°C

| Type | Picture | Vibration mode | Applicable materials | Application scenarios |

| Vibrating screen |

|

Three-dimensional rotary vibration | Fine powder, ultrafine powder, slurry | Fine screening, laboratory, small-scale production |

| Centrifugal screening machine |

|

Centrifugal force + rotation | Fibrous materials, high-viscosity materials | Large-scale production, fibrous material screening |

| Rotary screen |

|

Rotation + gravity | Coarse and fine material mixture, bulk materials | Coarse screening, pretreatment, separation of bulk impurities |

| Linear vibrating screen |

|

Linear motion | Granular, powdery materials | Large output, continuous production line |

| Ultrasonic vibrating screen |

|

High-frequency ultrasound + three-dimensional vibration | Fine, easy to clog, high-viscosity materials | High-quality iron powder production, special material screening |

Iron powder vibrating screen plays an important role in many industries through efficient screening and grading:

Metallurgical industry: It can be used to screen granular materials such as iron ore and slag for subsequent production and processing.

Chemical industry: It can be used to screen chemical raw materials, granular products, etc. to meet the requirements of different process flows.

Building materials industry: It can be used to screen granular materials such as sand, gravel, cement, etc., and used to produce building materials such as concrete and mortar.

Food processing: It can be used to screen granular materials such as food raw materials and seasonings to ensure product quality and safety.

Cosmetics industry: It can be used to screen powdered cosmetic raw materials to ensure the fineness and uniformity of the product.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.