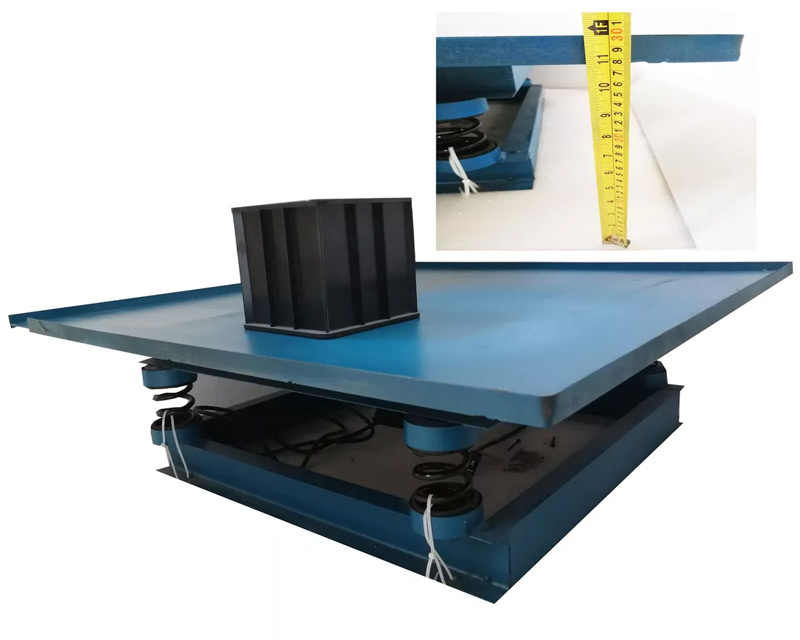

The spring of the vibration platform is also a key structure, which not only plays a transmission role, but also can absorb shock and buffer, greatly reducing the possibility of damage to the vibration platform, making the service life of the vibration platform longer and the vibration effect better.

The spring of the vibration platform is also a key structure, which not only plays a transmission role, but also can absorb shock and buffer, greatly reducing the possibility of damage to the vibration platform, making the service life of the vibration platform longer and the vibration effect better. Vibration platforms play a vital role in industrial production. When selecting vibration springs, multiple factors need to be considered, including the material, shape, stiffness, durability, etc. of the springs. The following is a detailed introduction to the selection of vibration springs for vibration platforms:

1. Simple structure and lower price;

2. There is no rigid metal structure, the spring shape and rubber ratio can be freely designed, and the stiffness and strength of the spring can be changed according to the use of the vibration platform and the actual pressure;

3. The actual use weight of the vibration platform is large. Compared with metal springs, rubber springs have greater pressure bearing capacity and stronger deformation recovery capacity;

4. The rubber structure can be closely connected with the metal structure of the vibration platform;

5. The rubber spring produces less noise.

There are four types of springs available for the vibration platform: rubber springs, metal springs, composite springs and air springs. Different springs have different characteristics and are suitable for different usage situations, so please choose according to the actual usage situation.

Factors that affect the selection of vibration springs for vibration platforms include the working environment of the vibration platform, vibration frequency requirements, load size, vibration amplitude, vibration direction, vibration duration, working stability requirements, installation space restrictions, etc.

The selection of vibration springs needs to consider these factors to ensure that the vibration platform can work stably and efficiently.

Different working environments and requirements may require vibration springs of different materials, stiffness and shapes. Therefore, when selecting vibration springs, these factors need to be considered comprehensively to meet the specific needs of the vibration platform.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.