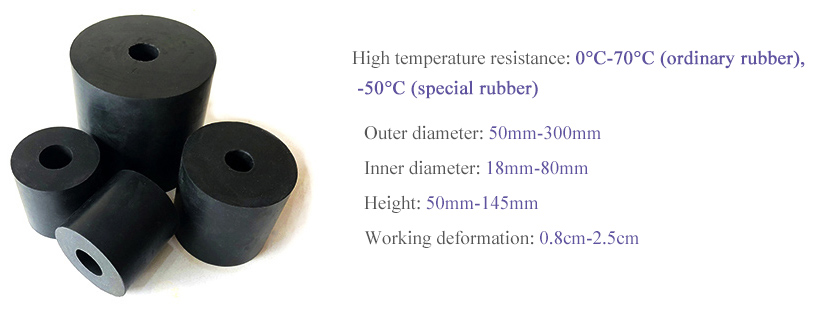

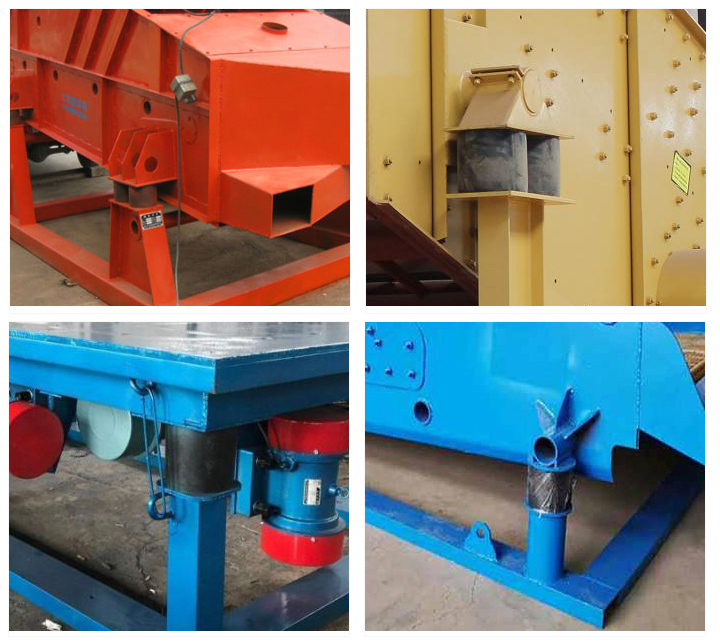

Rubber spring for vibrating screen is made of ordinary rubber, the elastic mold is small, the shape is not limited, and it has large elastic deformation. The rubber spring has high internal resistance, good shock absorption effect, small resonance field, and long service life. It has good cold resistance, air tightness, water resistance and electrical insulation, and can be used in vibrating screen, vibrating feeder, vibrating crusher, vibrating platform and other machinery.

Rubber spring for vibrating screen can be divided into rubber spring and composite rubber spring.

Rubber spring: It is a kind of high elastic body. It is made of ordinary rubber. It has a small elastic modulus and has a large elastic deformation after being loaded. It absorbs shock and vibration and can be loaded in multiple directions at the same time, but it has high temperature resistance. And oil resistance is worse than steel springs. If there are special requirements, it can be made of oil-resistant rubber.

Composite rubber spring: It is composed of metal coil spring and high-quality vulcanized rubber wrapped around it. It integrates the advantages of metal springs and rubber springs, and overcomes the shortcomings of metal springs, such as high rigidity, high working noise, low bearing capacity, poor shape and mechanical performance stability, etc. It has the advantages of better noise reduction effect, stable operation and short resonance interval.

|

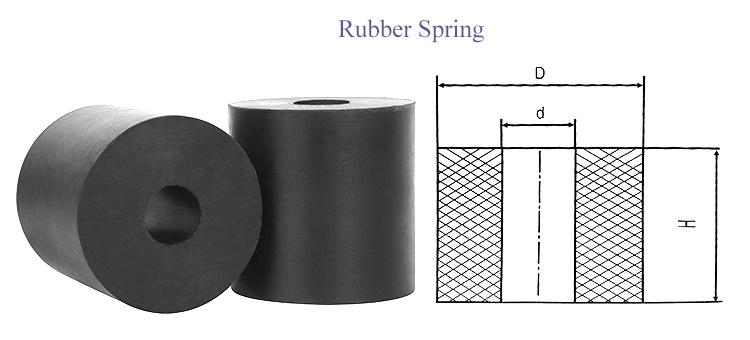

Specification D×H×d﹝mm﹞ |

Outer diameter D (mm) |

Inside diameterd (mm) |

Height H (mm) |

Work deformation FV (cm) |

Stiffness KL (kg/cm) |

Working load(Pa) |

| Ф50×50×Ф18 | 50 | 18 | 50 | 0.8 | 50 | 80 |

| Ф60×60×Ф20 | 60 | 20 | 60 | 0.8 | 60 | 100 |

| Ф80×80×Ф25 | 80 | 25 | 80 | 0.8 | 100 | 200 |

| Ф80×80×Ф30 | 80 | 30 | 80 | 0.8 | 100 | 200 |

| Ф100×100×Ф25 | 100 | 25 | 100 | 1 | 140 | 500 |

| Ф100×100×Ф30 | 100 | 30 | 100 | 1 | 140 | 500 |

| Ф100×130×Ф30 | 100 | 30 | 130 | 1 | 150 | 550 |

| Ф120×120×Ф30 | 120 | 30 | 120 | 1.2 | 220 | 600 |

| Ф120×140×Ф30 | 120 | 30 | 140 | 1.2 | 230 | 650 |

| Ф127×127×Ф30 | 127 | 30 | 127 | 1.2 | 230 | 640 |

| Ф130×130×Ф30 | 130 | 30 | 130 | 1.3 | 240 | 680 |

| Ф140×140×Ф30 | 140 | 30 | 140 | 1.4 | 300 | 700 |

| Ф140×160×Ф30 | 140 | 30 | 160 | 1.4 | 350 | 680 |

| Ф140×160×Ф40 | 160 | 40 | 160 | 1.4 | 350 | 680 |

| Ф160×160×Ф30 | 160 | 30 | 160 | 1.6 | 350 | 750 |

| Ф160×160×Ф40 | 160 | 40 | 160 | 1.6 | 350 | 750 |

| Ф160×160×Ф50 | 160 | 50 | 160 | 1.6 | 350 | 750 |

| Ф160×160×Ф60 | 160 | 60 | 160 | 1.6 | 350 | 750 |

| Ф160×235×Ф40 | 160 | 40 | 235 | 1.6 | 400 | 800 |

| Ф160×240×Ф40 | 160 | 40 | 240 | 1.6 | 400 | 800 |

| Ф180×180×Ф40 | 180 | 40 | 180 | 1.8 | 400 | 800 |

| Ф180×240×Ф40 | 180 | 40 | 240 | 1.8 | 400 | 1000 |

| Ф200×150 | 200 | 150 | 1.5 | 380 | 900 | |

| Ф200×150×Ф65 | 200 | 65 | 150 | 1.5 | 350 | 800 |

| Ф200×200×Ф40 | 200 | 40 | 200 | 2 | 450 | 1000 |

| Ф200×200×Ф50 | 200 | 50 | 200 | 2 | 450 | 1000 |

| Ф200×300×Ф50 | 200 | 50 | 300 | 2 | 480 | 1300 |

| Ф220×220×Ф40 | 220 | 40 | 220 | 2.2 | 500 | 1500 |

| Ф220×220×Ф50 | 220 | 50 | 220 | 2.2 | 500 | 1500 |

| Ф240×240×Ф50 | 240 | 50 | 240 | 2.4 | 550 | 1800 |

| Ф250×250×Ф50 | 250 | 50 | 250 | 2.5 | 580 | 2000 |

| Ф300×245×Ф80 | 300 | 80 | 245 | 1 | 480 | 2800 |

Advantage:

1. The shape is not limited, and the stiffness in all directions can be freely selected according to the design requirements.

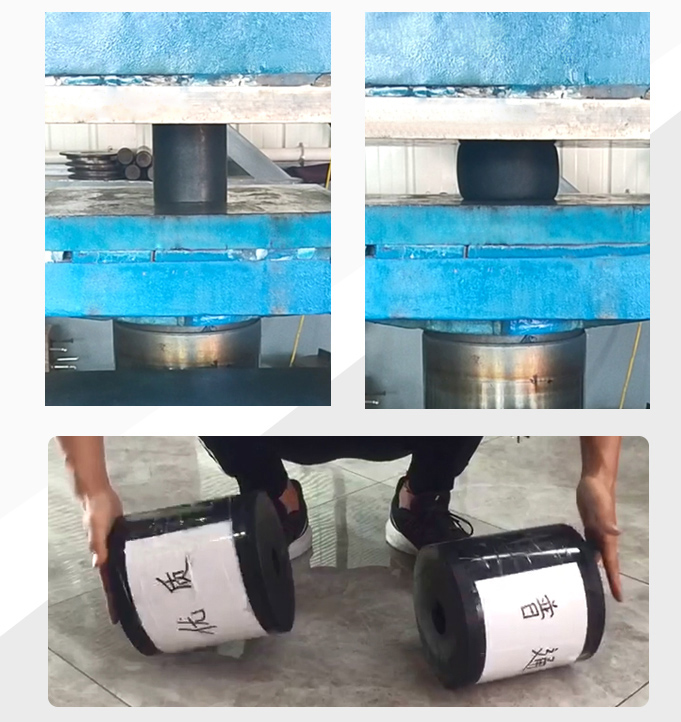

2. Although the elastic modulus is small, large elastic deformation can be obtained, and ideal nonlinear characteristics can be easily realized.

3. It has high internal resistance. This has a good effect on the absorption of sudden shocks and high frequency vibrations, as well as sound insulation.

4. The same rubber spring can bear multi-directional loads at the same time, thus simplifying the structure of the system.

5. Easy installation and disassembly, no need for lubrication, which is beneficial to maintenance.

Disadvantage:

1. The high and low temperature resistance and oil resistance are worse than that of steel springs.

2. Rubber springs are used in engineering. The shape is simpler than that of bellows, but it is quite difficult to accurately calculate their elastic properties.

3. Mainly because they are not pure elastomers, but are visco-elastic materials, so the mechanical properties are more complicated.

Rubber spring for vibrating screen can be used in vibrating screen equipment, double-decker passenger cars, trucks and other industrial machinery. It needs to be designed into various structural forms.

1. We can make rubber spring for vibrating screen into various shapes and sizes; and because of its compact structure, we can also effectively use the space.

2. Compared with metal, the elastic coefficient of rubber spring is much smaller than that of metal, and the change of rubber spring with hardness is relatively large, so we can achieve the purpose required by our production and use by changing the hardness of rubber. It is also possible to make the spring obtain a different stiffness, that is to say, we take the same shape of the rubber spring, and we can use some other external technologies to make the stiffness of the rubber spring within a certain range to choose independently. Therefore, the stiffness of the spring is changed by changing the internal structure of the spring, that is, changing the size of its central hole.

3. The stiffness of the rubber spring for vibrating screen in three different directions can be improved according to the actual production needs. In addition, the rubber spring can also bear the technology of shear deformation and compression deformation at the same time.

4. The resistance of the rubber spring to transmit sound is much larger than that of the metal spring, so the sound insulation effect of the rubber spring is better, and the noise generated by the rubber spring is relatively small when it is working.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.