Viscous powdery materials are easy to adhere to the surface of the screen during the screening process, resulting in the problem of blocking the screen, which brings certain difficulties and challenges to the screening operation. The sticky material vibrating screen is a screening equipment specially designed to handle sticky materials. Its working principle is based on vibrating screening technology, which separates and filters viscous materials through the vibration of the screen. However, the effects of different types of vibrating screens on viscous materials are quite different.

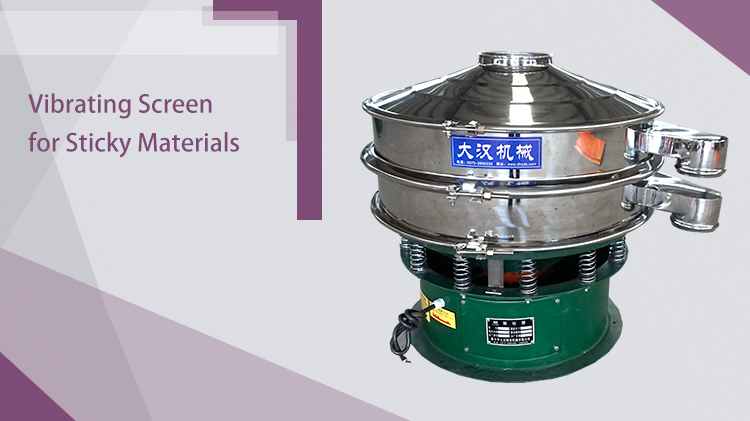

According to the specific production needs and characteristics of the viscous materials, it is key to select a suitable vibrating screen for viscous materials. Therefore, users should pay attention to this point when choosing a vibrating screen for viscous powder materials. If the selection is wrong, it will affect the screening accuracy and efficiency. In this regard, DAHAN Machinery recommends the following suitable for viscous powder materials. The vibrating screen for screening is described in detail as follows:

1. Ultrasonic vibrating screen

Ultrasonic transducer device solves the problem that sticky materials are easy to block the network

Powder-like viscous materials are difficult to sieve materials. The ultrasonic vibrating screen is equipped with a set of ultrasonic devices on the basis of ordinary rotary vibrating screens. For fine powder materials, for viscous materials with strong adsorption, ultrasonic vibrating screen can be solved by using ultrasonic transducer.

A low-amplitude, high-frequency ultrasonic vibration wave (mechanical wave) is introduced on the screen of the ultrasonic vibrating screen, and the ultra-fine powder receives a huge ultrasonic acceleration, so that the material on the screen surface of the ultrasonic vibrating screen is always in a suspended state, so as to avoid sticky materials. The problem of blocking the screen during the screening process.

In the case of solving the problem of viscous material blocking the mesh, the accuracy of the DAHAN ultrasonic vibrating screen can be increased by more than 80%, and the output can reach 1~10t/h. Different types of ultrasonic vibrating screens have different output.

2. Tumbler screen

Artificial artificial design, suitable for difficult materials

During the screening process of viscous powder materials, due to their strong adsorption, they often cause the phenomenon of blocking the screen. The swing screen is a high-efficiency screening machine that simulates manual screening mechanically. The service life is 5-10 times longer than that of conventional round sieves, suitable for all fine and range powder and particulate materials, especially for difficult-to-handle materials.

The tumbler screen adopts the artificial design principle. The basic rotary motion driven by ordinary motor is similar to manual screening, so that the material forms a three-dimensional tumbling motion of horizontal and throwing on the screen, and is evenly dispersed on the entire screen surface from the center to the outer edge. , so that it propagates in the axial direction in a spiral motion, and adjusting the meridional and tangential angles on the pendulum body can change the movement trajectory of the material on the mesh surface.

The sieving particle size is 0.073~3mm, the sieving accuracy is as high as 90%~95%, the output per unit area is as high as 5 times, and the 6-stage separation, the sieving efficiency is as high as 90%~99%, and the processing capacity reaches 6-60t/h, In addition, the swing screen is equipped with rubber ball, ultrasonic and other net cleaning devices, the screen holes are not easy to be blocked, which can solve the problem of blocking the screen during the screening process of viscous materials.

Viscous materials increase the difficulty of screening, but choosing a suitable vibrating screen can greatly save the user's time and cost and create greater value for the enterprise. If you want to choose a suitable vibrating screen, you are welcome to consult with us online. Please click on the online chat directly on the page and I will answer your questions for you.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.