Vibro sifter is a common screening equipment, widely used in the screening and grading of granular materials. According to different working principles and structural characteristics, vibro sifters can be divided into many types and classifications, each of which has specific advantages and applicable scope. The following will introduce the types and classifications of vibro sifters in detail.

1. The rotary vibrating screen is suitable for classification, coarse screening and fine screening. Compact structure, high screening efficiency, adjustable bevel angle, horizontal or vertical layout, easy to use.

Overall, this type of vibrating screen is used to ensure a higher quality of the final product. While rotary vibrating screens can be placed anywhere on the production line, in most production environments inspection screens are either the first machine in the process, preventing contamination, or the last machine before packaging machines, for final quality examine. Depending on the material, bouncing balls and ultrasonic cleaning devices can be selected to solve the problem of network blocking caused by factors such as high water content and strong viscosity of the material.

2. Linear vibrating screens, as the name suggests, they move the product in a linear direction, so the use of a rectangular screen allows the product more time to pass through the grid. In addition to sorting and removing impurities from the product, the linear screen can also efficiently transport the product, sometimes Can be used in place of traditional product conveyors as the vibration of the linear screen gently bounces the product forward.

Linear vibrating screens are particularly suitable for dry powdered or granular materials, as well as products with a high proportion of oversized particles, as their length allows fine products the opportunity to separate from larger particles and fall into the screen. This makes the linear sifter particularly suitable for dusting or dewatering operations, such as removing small loose crumbs and flour from finished biscuits.

3. Cyclone screens use a set of paddles to push the product out of the screen cylinder, rotating them at high speed and applying centrifugal force to the product. The cylinder is mounted horizontally so a slight twist is applied to the paddle to move the product down the length of the cylinder and the paddle is fed at a steady rate using an auger.

These paddles force product through the screens, giving them a higher throughput than vibrating screens. The motion of the rotating auger and paddle assembly has the added benefit of breaking up clumps or separating compacted products.

4. The discharge port of the straight row sieve is designed at the bottom of the screen, which is beneficial to increase the discharge speed and discharge volume. The output is 2-5 times that of ordinary circular vibrating screens. It is suitable for coarse screening of materials other than impurities.

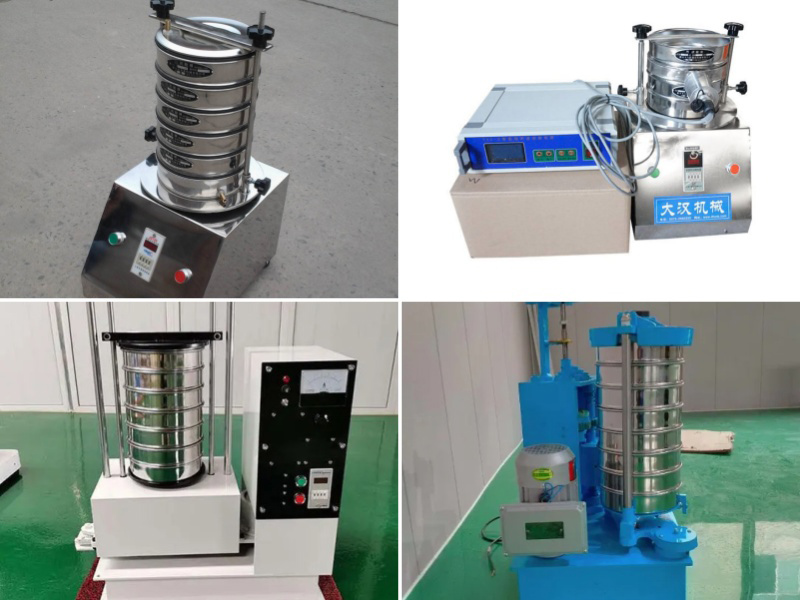

1. The standard test sieve can quickly and effectively measure the size of solid particles from 125mm to 20μm. The particle size measured by test sieving can be specified simply by referencing two sieve sizes, one through which the particles have passed and the other through which they are retained, i.e. the particle size distribution.

2. Ultrasonic test sieve can easily sieve high-fine powders that cannot be detected by ordinary sieving machines, as well as materials that are blocked due to high static electricity, strong adsorption, high density, and light specific gravity.

3. There is a reciprocating suspension movement inside the material of the magnetic levitation test sieve, and no material will remain on the sieve when sieving, and the minimum sieve can reach 5 microns.

4. Two kinds of vibrations, reciprocating and slapping, ensure that the material is discharged quickly and does not block. It can be equipped with special clamps, which can clamp Φ200 standard screen frames and Φ75, Φ100 screen frames. The clamping is convenient and flexible, the clamping is firm, and it can automatically shut down at a fixed time. It is especially suitable for diamond powder and superhard materials.

1. ZSG mining vibrating screen is widely used in mining, coal, electric power, fireproof materials, metallurgy, building materials and other industries for screening and grading of large, medium and small particle materials.

2. The material movement track of the circular vibrating screen is a circular motion, which is used to screen bulk materials with medium to coarse grain size (5.0 mm to 100 mm).

3. Dewatering screen In order to effectively dehydrate the material, the slurry is sent to the steep downward-sloping screen surface at the feed end of the dewatering screen to achieve rapid drainage and then discharge the dried product. It is mostly used in tailings dry discharge, water washing sand, coal slime recovery and other industries.

Like other processes in a production line, screening presents a set of challenges that vary according to the material being processed, the throughput of the line, environmental variations, and the standard and finish of the equipment. The above content has outlined the main types of vibrating screens. In addition, vibrating screens can also adopt other configurations and special customizations according to requirements.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.