Titanium dioxide screening by rotary vibrating screen is a common practice in industries such as paint, coatings, plastics, and cosmetics. Titanium dioxide, a white pigment known for its opacity and brightness, requires precise screening to ensure product quality and consistency.

Coarse particles (larger than 45 microns) may reduce opacity and brightness, making them unsuitable for high-quality coatings or cosmetics.

Medium particles (10–45 microns) are often used in industrial applications like plastics and paints.

Fine particles (less than 10 microns) are ideal for premium applications such as cosmetics, pharmaceuticals, and food-grade products.

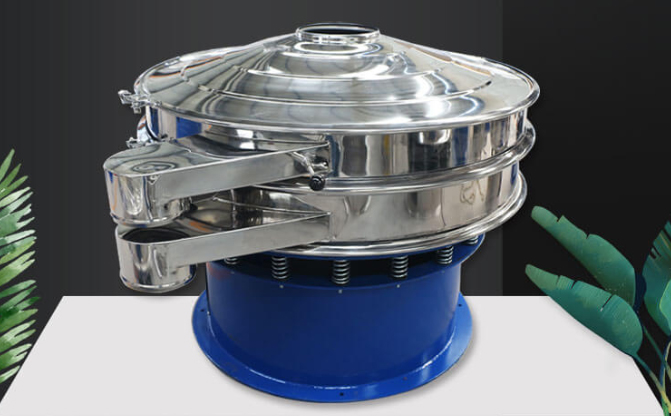

To achieve the desired particle size distribution, titanium dioxide powder must be screened using advanced equipment like rotary vibrating screens.

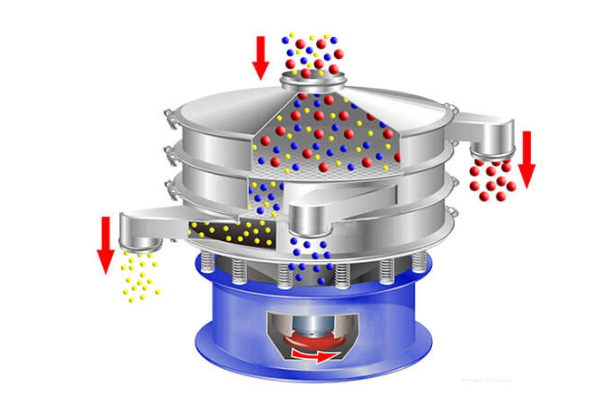

Screening Surface: The rotary vibrating screen consists of a screen mesh that vibrates in a circular motion. This motion helps separate and classify titanium dioxide based on particle size.

Vibration Mechanism: The screen is equipped with an eccentric weight system that generates vibrations, causing the particles to move along the screen surface and pass through the mesh openings.

Multiple Layers: Some rotary vibrating screens have multiple layers of screens with different mesh sizes, allowing for precise classification of titanium dioxide into various particle size fractions.

A rotary vibrating screen is a multi-layer, high-precision screening machine that uses vibration motors to generate a three-dimensional motion (vertical, horizontal, and rotational). This motion ensures efficient separation of particles based on size. Key features include:

Adjustable Mesh Sizes: Screens with different mesh sizes (e.g., 100 mesh, 200 mesh, 325 mesh) can be used to classify titanium dioxide into various grades.

Coarse Screening (20–100 mesh): Used to remove large agglomerates or impurities from raw titanium dioxide powder. Ensures the material is ready for further refinement.

Medium Screening (100–325 mesh): Separates titanium dioxide into medium-sized particles suitable for industrial applications. Commonly used in paints, coatings, and plastics.

Fine Screening (325–500 mesh or higher): Produces ultra-fine titanium dioxide powder for high-end applications. Essential for cosmetics (e.g., foundations, sunscreens) and food-grade products.

Screening titanium dioxide using a rotary vibrating screen is a critical step in the production process to ensure product quality, consistency, and purity. By employing this efficient and versatile screening technology, manufacturers can achieve precise particle size distribution, improve production efficiency, and meet the stringent quality standards required in industries where titanium dioxide is a key ingredient. Investing in high-quality rotary vibrating screens tailored for titanium dioxide screening can enhance overall process efficiency and product quality in various industrial applications.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.