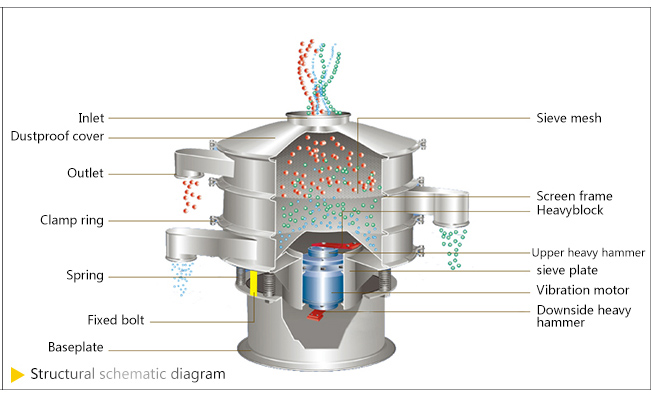

Vibrating sieve is a screening equipment for 2~500 mesh granule, powder, slurry material screening, filtration and impurity removal. The equipment can be widely used in food, medicine, chemical industry, metal metallurgy, ceramics and other industries. screening work. So what structures are vibrating sieves composed of? The following editor will explain to you the structure and function of vibrating sieve.

1. Bottomof the vibrating sieve

The bottom of the Vibrating sieve contains a vertical vibration motor, a bottom bucket, and a vibration plate.

1. Vertical vibration motor: as a power supply component, the vibrating sieve uses a vertical vibration motor, and the motor power can be freely selected from 0.18KW to 4.0KW. (The larger the diameter of the equipment, the higher the motor power used. Big). For some special industries, it can be equipped with explosion-proof vibration motor;

2. Bottom barrel: This part plays the role of supporting the screen body and bearing the vibration motor. The thickness of the replacement shift is 3mm~6mm, and the thickness is also determined according to the diameter of the equipment;

3. Vibration plate: This part plays the role of fixing the vibration motor and connecting the screen body. The plate used is Q235 carbon steel with a thickness of 4mm~6mm;

2.The top half of the vibrating sieve

The upper part of the Vibrating sieve includes the screen frame, the beam ring, the screen, the punching plate, the screen cleaning device, and the upper cover.

1. Screen frame: This part acts as a constraining material to make the material produced within a certain range. Common materials are Q235 carbon steel and 304 stainless steel, and the material thickness is 2.0mm~3.0mm.

2. Beam ring: This part plays the role of connecting the bottom cone and the screen frame, the upper and lower screen frames, and also plays the role of preventing material leakage.

3. Screen: The parts that are in direct contact with the material play a role in improving the screening accuracy and product quality. The commonly used material is 304 stainless steel woven mesh.

4. Punching plate: This part is used to lift the screen and prolong the service life of the screen. The commonly used material is 304 stainless steel.

5. Cleaning device: It can be divided into three kinds of cleaning devices: bouncing ball, ultrasonic wave and rotating brush. Users can choose reasonably according to different production processes.

6. Upper cover: It plays a sealing role and can effectively dissipate dust.

The above is the name and function of each component of vibrating sieve. Each type of vibrating sieve equipment has its application field and function, and the relevant parts of each type of equipment also need to be reasonably selected and produced according to the user's production process, so if you need to customize vibrating sieve, please provide your detailed requirements, Dahan The machinery will be tailored to you according to your requirements. If you want to know more products, please contact Dahan Machinery.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.