Vibrating sieve accessories include: vibration motor, damping spring, bearing, sealing strip, screen, and cleaning device. When selecting, it is necessary to select according to the production materials and production requirements. When choosing vibrating sieve accessories, you need to pay attention to the following points.

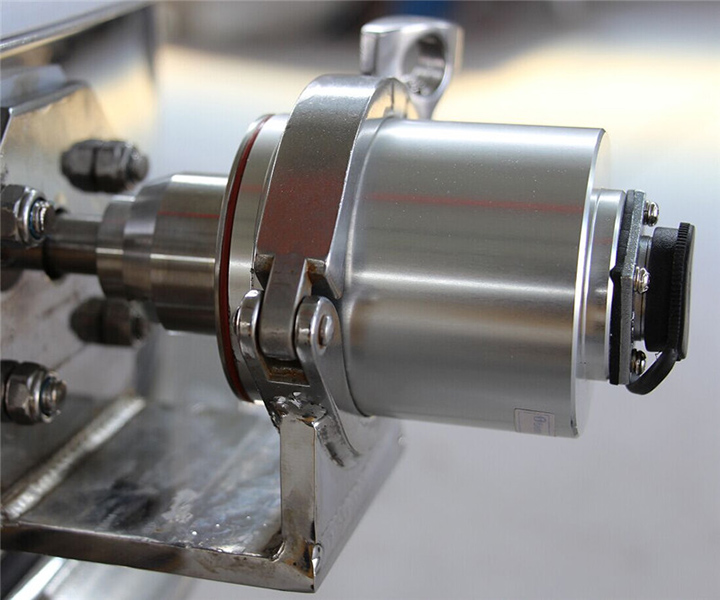

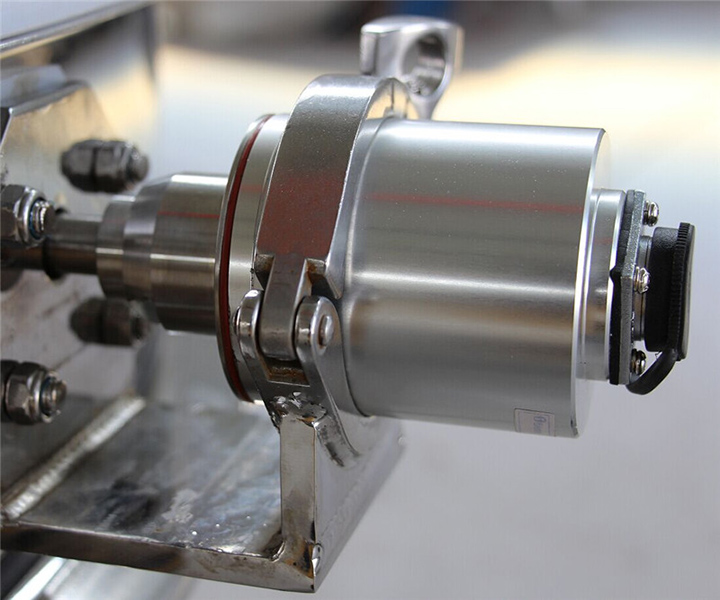

1. Vibration motor: as the power source of the vibrating sieve, the greater the power of the motor, the higher the output and the screening accuracy of the equipment. However, the power of the vibration motor configured by different types of vibrating sieve is also different, so it should be selected reasonably. On the other hand, vibration motors can be divided into two types: ordinary and explosion-proof. If there is no open flame or overheating in the production environment or materials, please use explosion-proof vibration motors.

2. Shock-absorbing spring: The shock-absorbing spring can not only reduce the resonance of the equipment, but also play the role of connecting the base and the screen frame. The shock-absorbing spring can be divided into steel springs, composite springs, and rubber springs. Different types of equipment use shock-absorbing springs. Springs are also different, so please choose reasonably when choosing.

3. Bearing: Bearing is an important part linking the vibration motor and the screen frame, and it is the part that realizes the vibration of the screen frame. The selection of bearings can be divided into domestic bearings and imported bearings. The price of imported bearings is higher than that of domestic ones, but whether it is Quality or noise is better than domestic bearings. Therefore, please choose according to the actual production requirements when choosing.

4. Sealing strips: Silicone sealing strips are commonly used by vibrating sieve manufacturers today. When selecting, please select the corresponding sealing strips reasonably according to the diameter of the sieve frame.

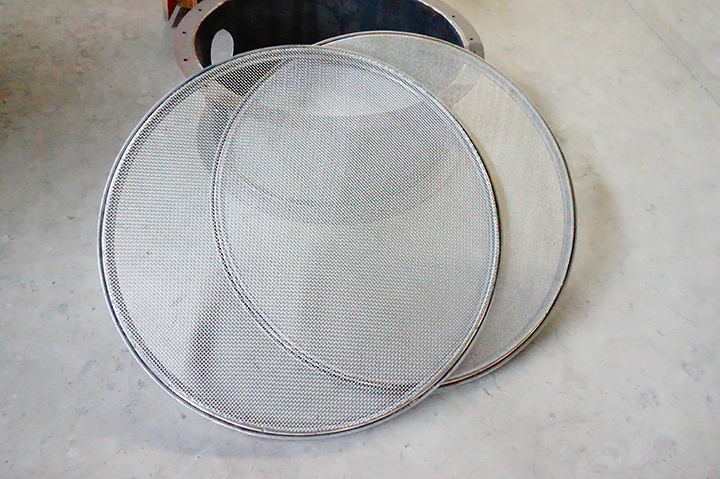

5. Screen: For the parts directly in contact with the material, the quality of the screen determines the output and screening accuracy. The screen can be divided into metal woven mesh and punching plate. When screening small particles, powder, and slurry. Metal woven screen can be used for materials, such as punching plate screen for larger diameter materials.

6. Cleaning device: When the vibrating sieve is produced due to the shape of the material, the mesh will be embedded and the mesh will be blocked, which requires the use of a cleaning device for cleaning. Cleaning devices include: bouncing ball cleaning device and ultrasonic cleaning device. The bouncing ball cleaning device is more commonly used. The device can clean up the blockage of materials below 200 mesh. Ultrasonic cleaning device is a new type of cleaning equipment. It uses high-frequency and low-amplitude ultrasonic waves to float the material on the screen surface to achieve the effect of cleaning the screen. The ultrasonic cleaning device can clean up the blocking, sticking, adsorption, troupe and other problems of materials below 500 mesh.

The above are some of the issues that need to be paid attention to when choosing accessories for vibrating sieve. A high-quality vibrating sieve needs good accessories for auxiliary work, so that the performance of the equipment can reach the ideal state. If you encounter difficult problems when purchasing or using, you can contact Dahan Machinery at any time.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.