vibrating sieve is a mechanical equipment for sieving fine particles, powders and slurries. Its advantages lie in high screening accuracy, small size, low energy consumption, and good dust-proof effect. The secret of vibrating sieve dustproof is that it uses sealing ring. There are many types of sealing rings, which can be divided into: rubber material, silicone material, polyurethane material, and should be equipped with suitable materials according to different occasions. Under normal circumstances, the silicone material is better than the rubber material. The main advantages of silicone are strong wear resistance and good elasticity. It is the most widely used in the food industry, and the rubber material sealing ring has a low cost and is more easily accepted by users. The following will explain various sealing rings for users. What are the characteristics of:

1. Rubber material

It is the most widely used in all kinds of sealing rings, but it is less used in the food and chemical industries. The rubber itself will have certain pollution components for the material. The rubber skin is easy to fall off during screening, which affects the quality of the material. Strong abrasiveness. When purchasing vibrating sieve, users should install appropriate sealing rings according to different requirements of materials.

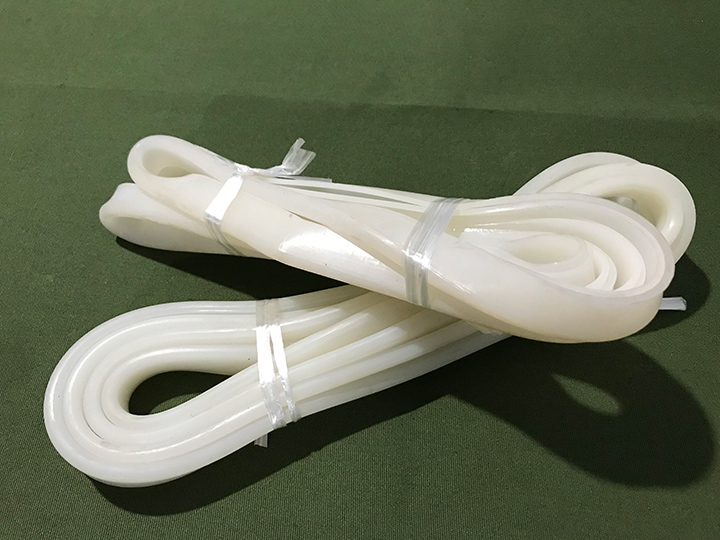

2. Silicone material

The color is milky white, and its softness is good, so it has the best dustproof effect in the sealing material. Choose silicone material as the first choice for dust prevention as much as possible, although the cost is higher, but the actual value is much higher than the other two materials.

No matter what kind of sealing ring, it is best to choose the one suitable for your own production. Please be sure to provide detailed parameters when we purchase. Such as material particle size, required output, material characteristics, etc., if you have any questions when purchasing vibrating sieve, please contact us.

3. Polyurethane material

Polyurethane materials are usually used in mining screen meshes and feeder linings. Vibrating sieves are rarely used as sealing rings to prevent dust, but sealing rings made of polyurethane materials are also more common in mining environments. Polyurethane is more common than silicone. , The rubber material is more wear-resistant, but the hardness is higher.

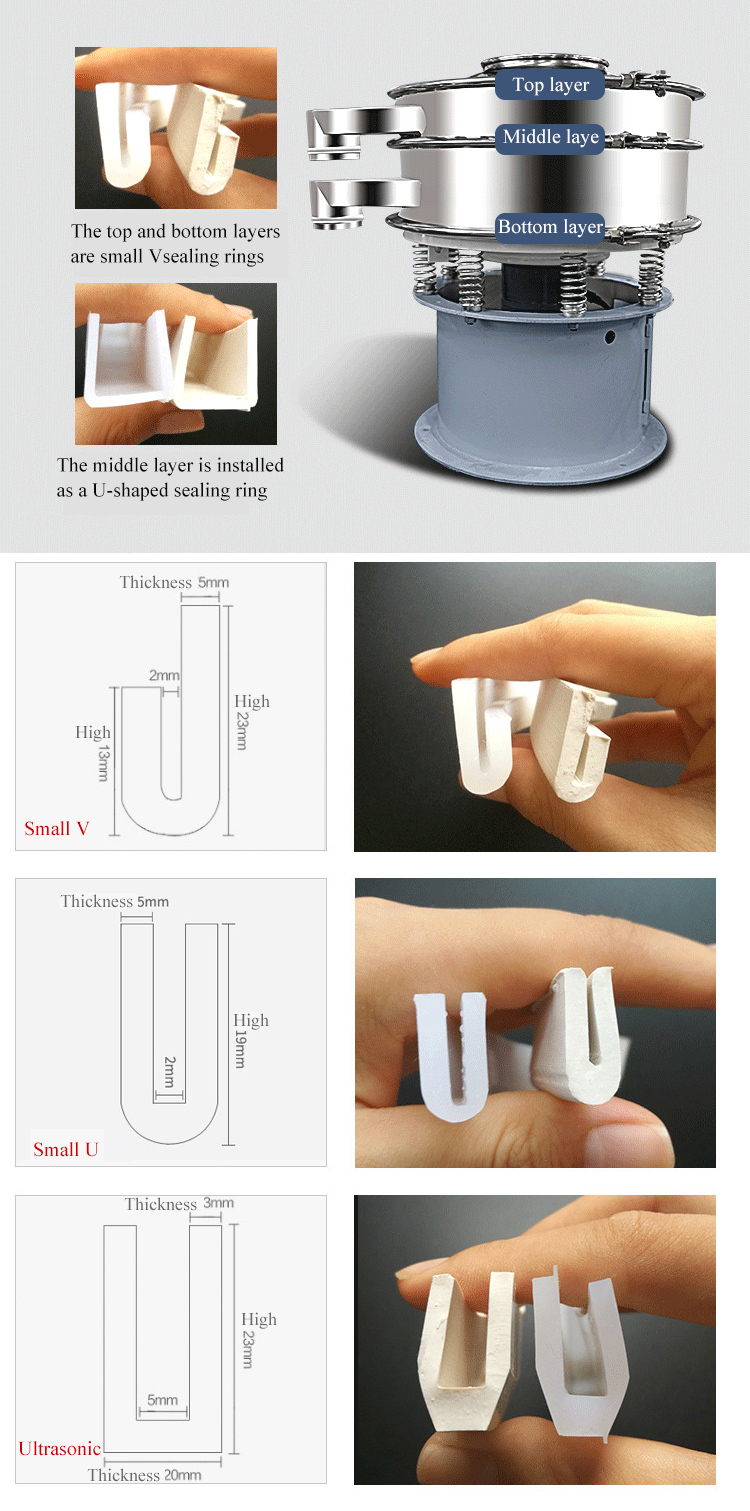

4. Installation location

Vibrating sieve sealing ring is an indispensable accessory in vibrating sieve. The sealing ring can avoid the exposure of raw materials, and also relieve the impact of the ibrating sieve on the screen frame during vibration. The sealing ring is generally divided into U-shaped and V-shaped. The key is to use the letter ball. Mesh frame and sealing cover on top.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.