Screw conveyors can be divided into horizontal, inclined and vertical according to the conveying angle. Vertical screw conveyors and horizontal screw conveyors are common screw conveying equipment, and they play an important role in industrial production. Each has specific advantages and applicable scenarios, providing diversified conveying solutions for industrial production.

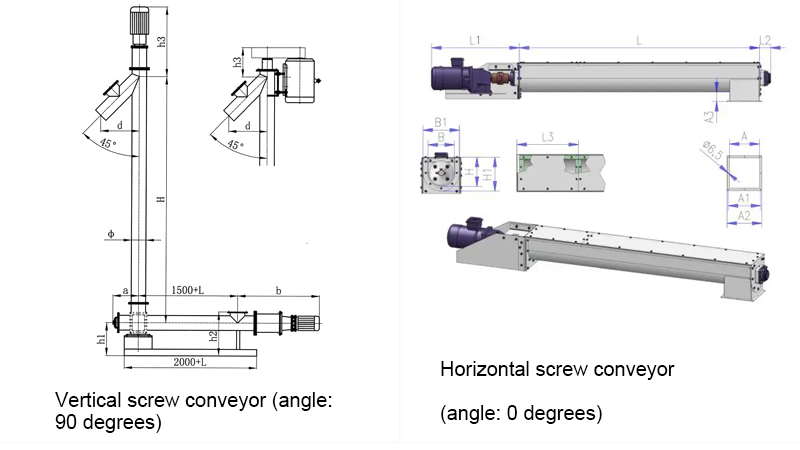

Vertical screw conveyors and horizontal screw conveyors are roughly the same in structure, and they are composed of driving device (motor, reducer, coupling), screw, bearing, material trough, feed port, discharge port, etc. But they are also very different in terms of working principle, conveying angle, conveying height and capacity. This article will mainly introduce you to the difference between vertical screw conveyor and horizontal screw conveyor:

The working principle of the vertical screw conveyor: the material is moved forward along the displacement direction of the screw by the rotating screw blade. The material is subjected to the centrifugal force of the rotating screw during the conveying process and the friction between its own gravity and the casing to achieve The effect of upward transport.

The working principle of the horizontal screw conveyor: the material is conveyed along the displacement direction by the rotating screw blade, which relies on the double force of the material's own gravity and the friction force of the screw conveyor casing on the material; and the displacement of the material in the middle bearing depends on The material is conveyed by the thrust of the forward movement of the material behind.

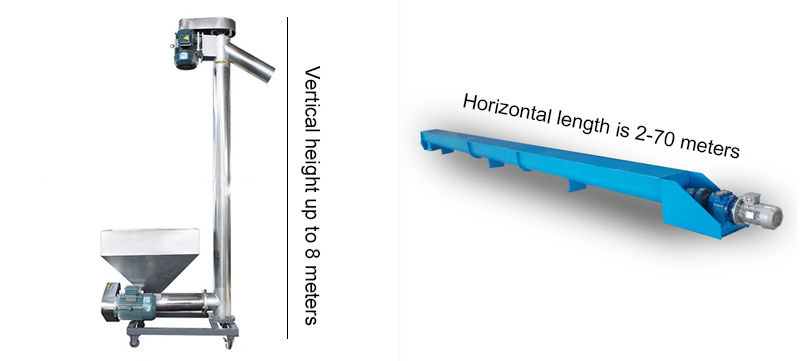

The vertical Screw conveyor is suitable for conveying powdery, granular, non-sticky dry materials with a bulk density of ≤1.3t/m in the vertical 90° direction, and the horizontal screw conveyor is suitable for horizontal or slightly inclined (≤20°) continuous and uniform conveying of loose materials .

Vertical spiral conveying height: from 2.5 meters to 15 meters, 0.5 meters in one grade, users can choose according to their needs.

Conveying length of horizontal screw conveyor: The diameter of the screw is 100~1250mm, and the length is 2-70 meters. Special specifications can be made according to customer requirements.

Conveying capacity of vertical screw conveyor: 140 cubic meters per hour.

Conveying capacity of horizontal screw conveyor: 381 cubic meters per hour.

The difference between vertical screw conveyor and horizontal screw conveyor is introduced here. If you want to know more details about them, please click on our product page to view or directly click on the online chat on the page for consultation. Your inquiries are always welcome and we will be honored to answer your questions.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.