Sieving is an important process used in the production of dried herbs, helping to ensure that they are safe, of consistent quality, and suitable for consumption or use in other products. The following is an introduction to the application of sieving machine in dried herbs.

1. Classification: Classify according to the particle size of dried herbs. This helps to ensure consistent quality and appearance of the herb, making it easier to package and distribute. This is very important to maintain the freshness and quality of herbs during storage and transportation.

2. Removal of impurities: Used to remove any impurities or foreign matter that may exist in dried herbs. This helps ensure that dried herbs are safe to eat and meet the required quality standards.

3. Extraction: Used to extract active ingredients from dried herbs, by ensuring the particle size of dried herbs is consistent, the extraction process can be more efficient and effective.

Sieving Machine for Dried Herbs

Dry Herbs Sieving Machine

The table below shows you the difference between sieving dried herbs by hand and by sieving machine:

| Compare items | Sieving Dried Herbs by Sieving Machine | Hand Sieving Dried Herbs |

| Capacity | Machine screening is a more automated and efficient process, faster than manual screening, with a single output of 100-3300 kg/h, generally inclined to large-scale commercial production | Manual sieving 100 kg/hour per person, suitable for small size inspection |

| Performance | It can work continuously for 24 hours to ensure that there will be no pollution, hair and other sundries mixed with raw materials | Manual sieving does not meet the GMP standard, and there is no labor protection. If it lasts for more than 1 hour, it will easily cause workers to be overworked and cause production problems or even accidents. |

| Cost | The machine is unmanned and can be used for a long time | Human screening can be time consuming and may not be as effective as machine screening. |

| Accuracy efficiency | Machine screening can be more accurate, ensuring a more uniform grain size and texture | The accuracy of manual screening is not up to standard and unstable |

| GMP standard | Standards compliant | Incompatible |

There are several advantages to using a screener to produce dried herbs. Here are some key advantages of using a dried herbs sieving machine:

1. Improve quality control: Helps to ensure consistent particle size of dried medicinal materials, which is very important to maintain the quality of medicinal materials. This allows for better quality control and helps ensure that the herbs meet the required specifications.

2. Improve efficiency: It can quickly and efficiently process a large number of dried herbs. This reduces the need for manual labor and increases the overall efficiency of dried herbs processing operations.

3. Pharmaceutical grade: Made of SS304/316L stainless steel polishing, the equipment is clean and hygienic, the production process will not pollute the medicine, and it meets the hygiene standards of the pharmaceutical industry.

4. High efficiency: Suitable for screening range from 36 microns to 25 mm, output from 100 to 5,000 kg/hour, depending on the product, mesh size and feed flow of the machine.

5. Cost-effective: Using sieving machine is a cost-effective solution for grading and screening dried herbs. It reduces the need for manual labor and increases the efficiency of herb processing operations.

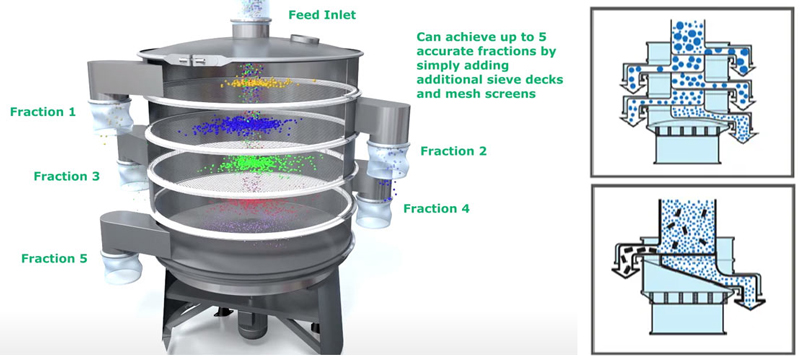

6. Multi-layer grading: Continuous filtration for up to 5-stage product separation in just 1 operation, available in a variety of sizes for smaller and larger scale operations from 400 to 2000.

One client case involved a company that produced a variety of dried herbs for culinary and medicinal applications. The company had issues with the quality and consistency of their dried herbs, which affected their ability to meet customer demand.

The company decided to invest in a dried herbs sieving machine to improve its production process. The sieving machine is customized to meet the company's specific needs, including the required granularity and throughput.

After using the sieving machine, the company saw a dramatic improvement in the quality and consistency of the dried herbs. The machine is capable of removing any impurities or foreign matter present in the herbal medicine to produce a higher quality product, featuring a premium stainless steel body with pharmaceutical grade gaskets and rubber to ensure it meets the hygienic standards required by the pharmaceutical industry. . The machine also processes dried herbs more efficiently, reducing the need for manual labor and increasing overall efficiency.

Thanks to these improvements, the company is able to increase production capacity and meet customer demand more efficiently. They have also received positive feedback from customers on the quality and consistency of their dried herbs.

Overall, the use of dried herbs sieving machine has helped the company improve the production process, increase efficiency, and produce higher quality products, resulting in higher customer satisfaction and business growth.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.