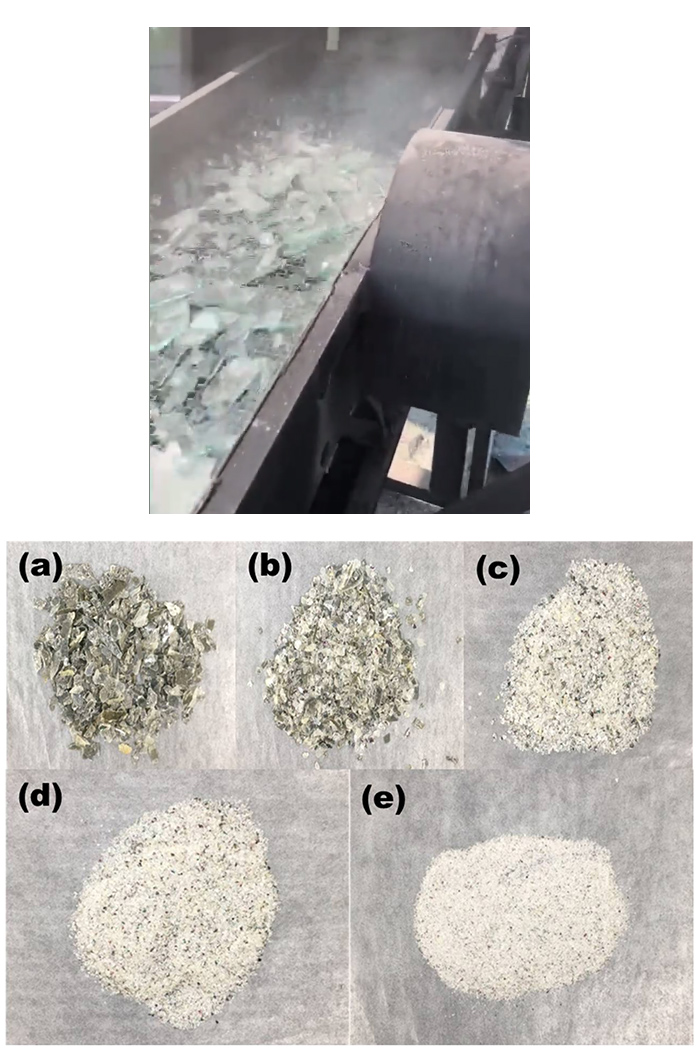

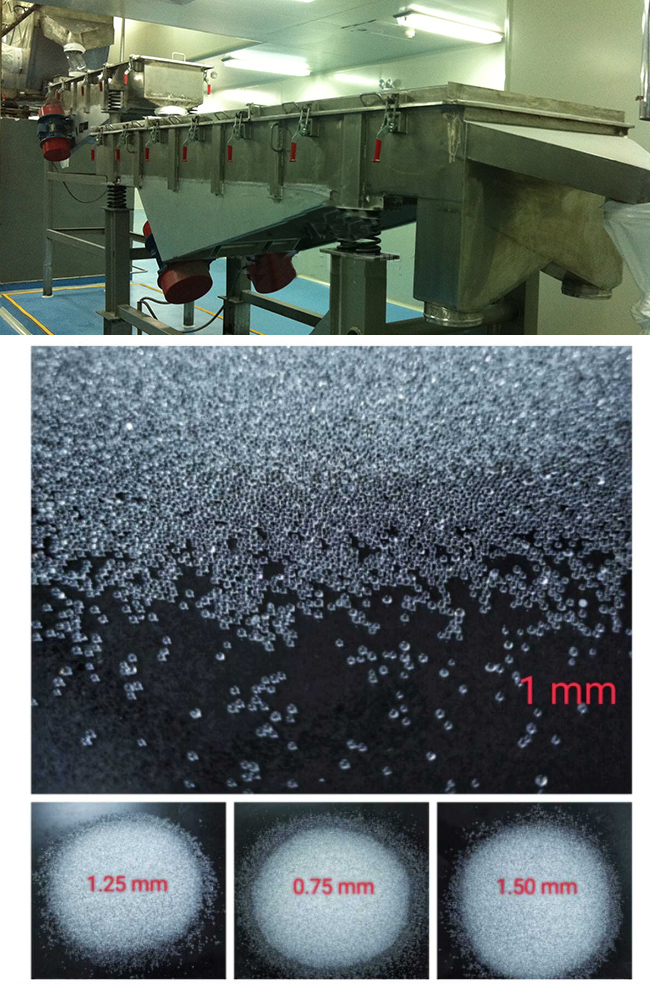

Vibrating screen for removing impurities from cullet is a specialized equipment used in the glass recycling industry to separate and remove contaminants or foreign materials from cullet, which is crushed orcullet. It helps to ensure the quality and purity of the recycled glass.

Vibrating screen for removing impurities from cullet can effectively screencullet,When sieving cullet in the glass recycling industry, common mesh sizes are selected based on the desired particle size distribution and the specific requirements of the glass production process. Here are some common mesh sizes used for sieving cullet:

10 mesh (2.00 mm): This is a relatively coarse mesh size used to remove larger impurities and separate larger cullet particles.

20 mesh (0.84 mm): This mesh size helps to remove intermediate-sized impurities and is suitable for separating cullet particles of moderate size.

30 mesh (0.60 mm): It is used to separate smaller impurities and refine the cullet particle size distribution.

40 mesh (0.42 mm): This mesh size further refines the cullet particle size distribution, removing finer impurities.

60 mesh (0.25 mm): It is used for fine screening of cullet, ensuring a more uniform particle size distribution.

80 mesh (0.18 mm): This finer mesh size is employed when a more refined particle size distribution is required for specific glass applications.

These are just a few examples of common mesh sizes used for sieving cullet. The actual mesh sizes selected may vary depending on the specific requirements of the glass production process, the desired cullet particle size distribution, and the quality standards in the recycling industry.

A vibrating screen usually consists of a screen and a vibrator. When the vibrator generates vibration force, the screen will vibrate at high frequency, so that the cullet particles are screened on the screen. Larger glass cullet particles are held back by the holes in the screen, while smaller impurities can fall through the holes in the screen into the collecting trough below.

The vibrating sieve has different mesh sizes, and the appropriate mesh size can be selected according to the needs. If larger impurities in cullet are to be removed, a smaller mesh size can be selected to ensure that only smaller particles can pass through the mesh. Conversely, if you want to remove smaller impurities in cullet, you can choose a larger mesh size.

1. High screening efficiency: it can effectively separate impurities from cullet particles. The linear motion of the screen allows smaller impurities to pass through the screen openings quickly and efficiently while retaining larger glass particles.

2. Precise particle size separation: The linear motion and design of the line screen allows for precise size adjustment and classification ofcullet particles, ensuring the desired particle size distribution is achieved. This is especially important in glass recycling, as different glass products may have specific size requirements.

3. Versatility in handling various impurities: Linear vibrating screens can effectively remove a variety of impurities fromcullet, including paper, plastic, metal, ceramics and other contaminants. Adjustable screen parameters, such as vibration intensity and screen openings, can be customized to specific impurity removal needs.

4. Large capacity: capable of handling large volumes ofcullet materials. They can handle large volumes of cullet, making them suitable for industrial-scale glass recycling operations.

5. Easy maintenance and operation: Compared with other types of vibrating screens, they generally have fewer moving parts, reducing the risk of mechanical failure. Routine maintenance, such as cleaning the screen or replacing a worn screen, is simple and can be completed with minimal downtime.

6. Sturdy structure: able to withstand the harsh conditions of the glass recycling industry. They are typically made from durable materials designed to handle the abrasive nature ofcullet particles.

The vibrating sieve is applied in the process of removing impurities from cullet, and cullet can be separated from impurities by sieving to ensure the quality of recycled cullet. When the vibrating screening screen is set reasonably, it can achieve high screening efficiency and achieve the purpose of removing impurities in broken glass.

In a word, vibrating sieve, as a commonly used solid particle screening equipment, can be widely used in the recycling process of cullet to remove impurities in cullet through sieving, so that it can meet the requirements of reuse. Its simple, efficient and environmentally friendly features make it one of the indispensable equipment in this field.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.