Vibro sifter for aluminum hydroxide can be used for aluminum hydroxide in a variety of applications. Aluminum hydroxide is a common compound used in industries such as pharmaceuticals, ceramics and flame retardants.

1. Particle size classification: Materials can be effectively classified into different particle size fractions. This helps ensure uniformity and consistency of aluminum hydroxide for a variety of applications.

2. Quality control: It can help remove excessively large or small particles, impurities and foreign matter to ensure the overall quality of aluminum hydroxide.

3. Depolymerization: Aluminum hydroxide particles may agglomerate or form clusters during storage or transportation. A vibro sifter with appropriate mesh openings and vibration intensity can break down these agglomerates, ensure a more even distribution of particles, and improve the flowability of the material.

4. Impurity separation: Aluminum hydroxide may contain impurities or contaminants that need to be removed. vibro sifter can effectively separate these impurities from aluminum hydroxide, ensuring a purer and higher quality product.

In summary, vibrating screens are important tools in the aluminum hydroxide industry for particle size classification, quality control, deagglomeration, impurity separation and safety screening. It helps achieve consistent particle size distribution, improves product quality, and ensures aluminum hydroxide meets the required properties for a variety of applications.

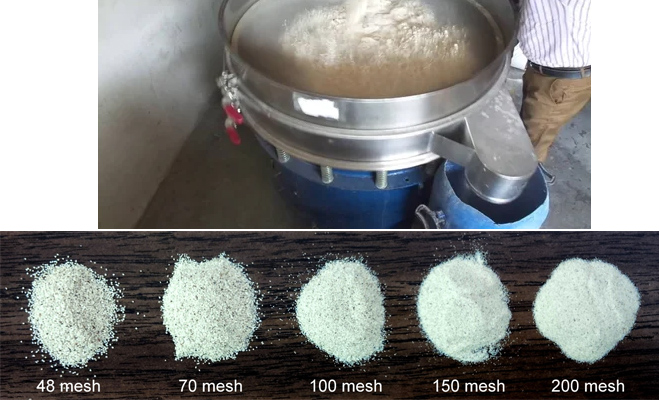

The selection of mesh sizes for vibrating screens used in aluminum hydroxide applications can vary depending on the specific requirements of the process and the desired particle size distribution. However, there are some commonly used mesh sizes that are often employed in aluminum hydroxide vibrating screens. Here are a few examples:

40 mesh (particle size range: 425 - 355 microns): This mesh size is often used as a coarse screen to remove larger particles and impurities from aluminum hydroxide.

80 mesh (particle size range: 180 - 225 microns): This mesh size is commonly used for primary screening of aluminum hydroxide to remove particles that are too large or inconsistent in size.

120 mesh (particle size range: 125 - 150 microns): This mesh size is often used for fine screening of aluminum hydroxide to achieve a more uniform particle size distribution and remove smaller impurities.

200 mesh (particle size range: 75 - 90 microns): This mesh size is utilized for finer screening and classification of aluminum hydroxide to obtain a more refined and homogeneous product.

325 mesh (particle size range: 45 - 50 microns): This mesh size is commonly used for ultra-fine screening and classification of aluminum hydroxide, especially in applications where a very fine particle size is required.

Aluminum hydroxide is a white crystalline solid with good chemical stability and electrical conductivity. It is often used in the preparation of ceramics, coatings, catalysts and other materials. Due to the small particle size of aluminum hydroxide powder, traditional screening methods are often inefficient, and vibrating screens can effectively improve screening efficiency and reduce energy consumption, so they are widely used in the production process of aluminum hydroxide powder.

The working principle of the vibrating screen is to separate the materials to be screened on the screen by vibrating force. Among them, the vibrator is driven by a motor to generate high-frequency vibration, which makes the material rotate on the screen, thereby realizing layered screening. During this process, due to the action of vibration force, fine agglomerates easily pass through the sieve, while coarse particles are blocked on the sieve, thus realizing the separation of particles of different particle sizes.

Aluminum hydroxide for Vibro Sifter offers several advantages over traditional sieving methods. First of all, the screening efficiency of the vibrating screen is high, which can quickly separate the target particles and improve the production efficiency. Secondly, the vibrating screen has a large processing capacity, and can process multiple particles at the same time, which greatly improves work efficiency. At the same time, the screen mesh of the vibrating screen can be replaced according to the demand, which is suitable for the screening requirements of different particle sizes. In addition, the vibrating screen also has a simple structure, which is easy to maintain and clean, which greatly reduces the maintenance cost of the equipment.

To sum up, the aluminum hydroxide vibrating screen is an efficient and high-capacity screening equipment, which is widely used in the production process of aluminum hydroxide powder. The material to be sieved is layered and separated on the screen by vibrating force, and the classification of particles with different particle sizes is realized. The vibrating screen has the advantages of high efficiency and large processing capacity, and the structure is simple and easy to maintain.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.