Power sieving machine

Power sieving machine Stainless steel power sieving machine

Stainless steel power sieving machine Ultrasonic power sieving machine

Ultrasonic power sieving machine Power sieving machine with feed hopper

Power sieving machine with feed hopper Power sieving machine with silo

Power sieving machine with silo

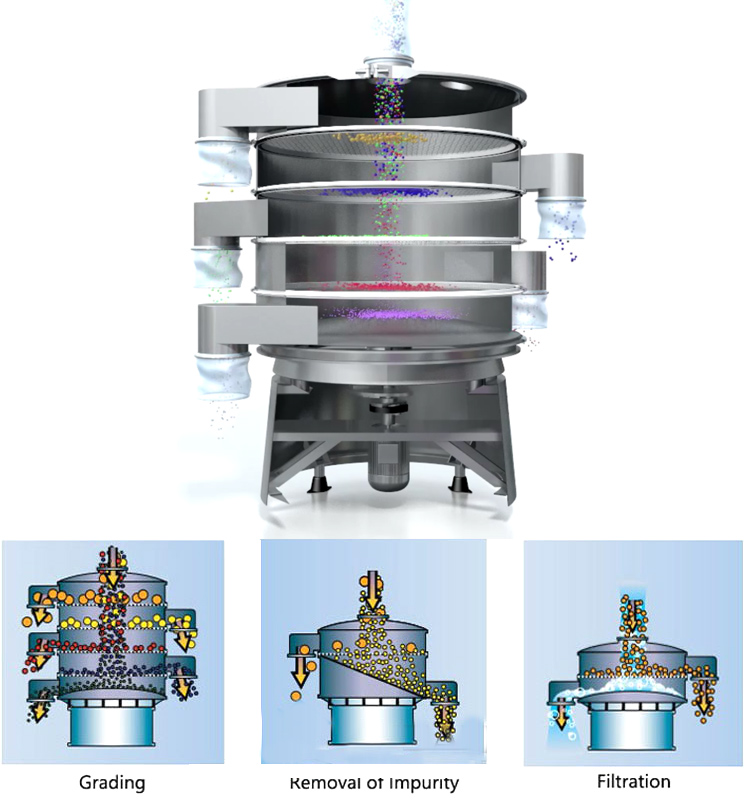

Remove all oversized contaminants from your powders and liquids and accurately grade by particle size requirements

![]()

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Function: Screening\separation\sorting\sieving\Grading

Diameter: 400-2000mm

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

Layer(s): 1-5 Layers

Material: Carbon Steel/Stainless Steel 304/316L

Voltage: 220v/380v/customized

Power: 0.18-2.2kw

Weight: 210 KG

Application: Designed for high capacity sieving of powders and liquids to remove oversize, suitable for dry or wet applications such as silica, ceramics, powder coatings, tapioca, coffee beans, copper powder, silver powder, etc.

Commitment:

Dry and wet screening machine with three-dimensional motion

Power sieving machine uses a general-purpose motor with a power of 0.18-2.2kw. Due to the simple adjustment of the counterweight on the motor shaft and the three-dimensional vibration they generate, our circular vibrating screen can screen, classify and dedust various products. and filtration, even fine products can achieve good results.

Power sieving machine is suitable for sieving from 36 microns to 25 mm, a variety of models (from Ø400 to Ø2000mm) can meet any type of requirements, it allows 100 to 3300 kg/h production, you can install 1 to 4 Separation stage, thus obtaining a grading of 2 to 5 products.

The power sieve machine is mainly composed of a inlet a dust cover, outlet a bundle ring, a screen mesh, a weight block, an upper weight hammer, a vibrating body, a vibration motor, a spring, a lower weight, and a base.

The vertical motor is used as the excitation source,an eccentric weight is mounted on the upper and lower ends of the motor. The rotary motion of the motor is converted into a horizontal, vertical, and inclined three-dimensional motion, and then the motion is transmitted to the screen surface, so that the material expands and expands on the screen surface, and the material smaller than the sieve aperture passes through The sieve hole falls to the lower layer and becomes the undersize material. The material larger than the sieve aperture has been discharged from the discharge opening after continuous jumping movement, and finally the screening work is completed.

1. Improve product quality: It can remove impurities and agglomeration in the material.

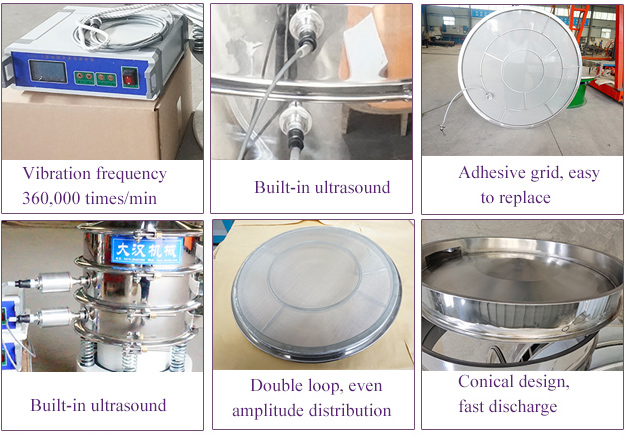

2. Sieve in fine mesh: Capable of sieving up to 500 mesh and providing the desired output, thus providing accurate particle size.

3. High throughput: The heavy-duty motion generator is a three-dimensional motion, which can generate higher vibrations compared to traditional sieving machines, resulting in 3 times higher throughput through precise sieving.

4. 5-stage separation: can provide up to 5-stage classification in one operation for precise particle size distribution

5. Easy to adjust: Equipped with a powerful vibration motor, which can adjust the weight and rotation angle of the motor.

Sieving heavy calcium powder

Sieving flour

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

| Model | Ordinary Sieving Machine | Power Sieving Machine | |||

| Test material | Mesh | Test Results | Mesh | Test Results | |

| φ1500 | Silicon carbide | 500 | Unable to sieve | 500 | 1500KG/H |

| φ400 | Tungsten carbide powder | 600 | No fine powder is sifted out in 15 minutes | 600 | 30KG/H |

| φ800 | Vitamin C powder | 100 | 1KG/H | 100 | 120-150KG/H |

| φ1000 | Pollen | 400 | No fine powder is sifted in 15 minutes | 400 | 20% fine work is sieved in 15 minutes for finer and more effective classification |

| φ600 | Nickel powder, cobalt powder | 400 | The sieve meets the requirements three times | 400 | The sieve meets the requirements at one time |

| φ400 | NdFeB powder | 300 | 32.2% sieve residue in 30 minutes | 300 | 6.9% sieve residue in 30 minutes |

Power sieving machine is commonly used in pharmaceutical powders, juices, plastic granules, additives, food powders and different types of powders, granules or slurries and is an ideal source for successfully screening foreign bodies, filtering impurities or classifying materials to ensure product quality.

Chemical industry: resins, coatings, medicines, cosmetics, oils, herbal powders, etc.

Food industry: sugar, monosodium glutamate, salt, fruit juice, starch, milk powder, food, soy milk, egg powder, rice, soybean, fish meal, pineapple juice, etc.

Paper industry: coating, waste liquid, paper waste liquid, waste water recycling, etc.

Metallurgical mining industry: quartz sand, sand, ore, titanium oxide, zinc oxide, etc.

Machinery industry: foundry sand, charcoal, baking paint, powder metallurgy, electromagnetic materials, metal powder, etc.

1).If you have ever used the machine,Pls give me the model directly.

2).If you never used this machine or you wanna us to recommend,Pls give me the information as below.

a).The material you wanna to sieve.(All stainless steel 304/316L,All carbon steel,Contact material part with sus304/316L)

b).The capacity(Tons/Hour) that you require?

c).The layers of the machine?--1-5 layer can be selected (1-4 layer has best screening effiency).

d).the mesh size of each layer.--2-500 mesh(More than 200 mesh,can use ultrasonic system )

e).Your local voltages.

f).The special requirement.

Xinxiang Dahan Machinery Co., Ltd. has a wide variety of power sieving machines - with user guides, ideal for use in different verticals for better sieving and filtration processes.

We also offer you customized solutions - for each specific industry.

We have a team of engineers involved in designing and customizing machines according to your needs

We ensure high quality and guarantee you will get it after double quality inspection

Every part of the machine is thoroughly monitored and inspected to ensure you get the best possible machine

Our prices are competitive and depend on the type of model you choose. Each model is tested and checked to ensure that it works smoothly and provides you with a complete solution.

You must read the details carefully, understand the mechanical model, technical specifications and features, and then place an order. We have multilingual professionals who ensure on-time and hassle-free delivery.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.