Sieving machine is a unique high capacity vibratory separator specially tailored for the dairy industry. The unit is best suited for removing curd particles from whey during cheese production and can also be used in butter production to recover butter particles from buttermilk. With a flow rate of up to 100,000 l/h, the machine increases the efficiency of cheese and buttermilk production while minimizing waste and reducing product downtime.

A sieving machine can be used for separating curds and whey in the cheese-making process. The process involves passing the mixture of curds and whey through a sieve or mesh, which separates the solid curds from the liquid whey. Here are the steps to use a sieving machine for curds and whey separation:

Prepare the curds and whey mixture: The curds and whey mixture is obtained by adding rennet to warm milk, which results in the separation of curds and whey.

Set up the sieving machine: The sieving machine should be clean and dry before use. Place the machine on a stable surface and ensure that the sieve or mesh is securely attached.

Pour the curds and whey mixture into the sieving machine: Slowly pour the mixture into the machine, making sure not to overflow it.

Turn on the machine: Turn on the machine and let it run until all the curds have been separated from the whey. The whey will pass through the sieve or mesh and collect in a container placed below the machine.

Collect the curds: Once all the curds have been separated, turn off the machine and collect the curds from the sieve or mesh. The curds can then be further processed, such as by pressing them into cheese.

Dispose of the whey: The whey collected in the container can be used for various purposes, such as feeding animals or as a fertilizer.

Note: Depending on the volume of curds and whey, a larger or smaller sieving machine may be required. It is also important to clean the machine thoroughly after each use to prevent contamination.

There are several advantages of using sieving machines for curd and whey separation in the dairy industry:

Efficiency: For handling large volumes of curd and whey mixtures, this allows them to efficiently separate the two components. This helps reduce processing time and increase productivity.

Consistency: Consistent separation of curds and whey is achieved, ensuring the final product is of consistent quality and meets required standards.

Automation: Screening machines are automated, which means the process can be controlled and monitored more efficiently. This reduces the risk of human error and ensures a more accurate separation of curds and whey.

Hygiene: Easy to clean and sanitize, helping to maintain a high level of hygiene in the processing environment. This is especially important in the dairy industry where hygiene standards are crucial.

Reduced product waste: While the curd is being collected, the whey processed through the unit can be separated in storage tanks, dried and processed into powder for further screening, meaning no processed product is wasted.

Cost-effective: Screening machines are cost-effective in the long run because they require minimal maintenance and have a long service life. This makes them a cost-effective solution for the separation of curds and whey in the dairy industry.

How does a sieving machine compare to other methods of curd and whey separation?

There are several methods of curd and whey separation used in the dairy industry, including centrifugation, filtration, and manual separation. Here is a comparison of sieving machines with other methods of curd and whey separation:

Efficiency: Sieving machines are highly efficient in separating curd and whey and can handle a large volume of mixture quickly.

Consistency: Sieving machines provide a consistent separation of curd and whey, ensuring that the quality of the final product is consistent and meets the required standards.

Automation: Sieving machines are automated, which means that the process can be controlled and monitored more effectively. This reduces the risk of human error and ensures a more accurate separation of curd and whey.

Hygiene: Sieving machines are designed to be easy to clean and sanitize, which helps to maintain a high level of hygiene in the processing environment.

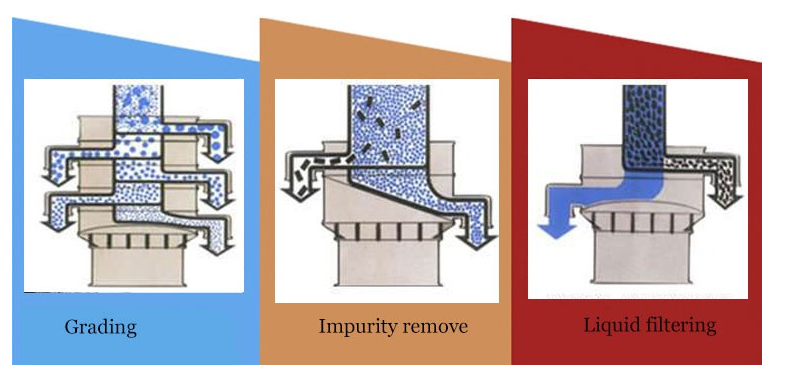

From milk filtration, curd and whey separation, to milk and whey powder screening, no matter what your dairy application needs, Dahan Machinery can provide solutions for various dairy processing applications. Each of these industrial manufacturing solutions can help safeguard the quality of your dairy products, from removing contaminants and oversized milk, filtering milk, to increasing productivity in the milk powder production process.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.