The shaftless screw conveyor adopts a shaftless design, which will not cause blockage due to the material sticking to the shaft, and can easily transport residues and pulper residues. So how much does a shaftless screw conveyor cost? The following will give you a detailed answer.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter (mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter (mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Inclination (a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Maximum length (m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Delivery volume (t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Price (USD) | 575-797 | 708-1003 | 960-1372 | 1254-1919 | 2300 | 3200 |

The above is the price range of shaftless screw conveyors under different models. Choosing different materials and designs will also lead to different prices of shaftless screw conveyors:

1. Different materials

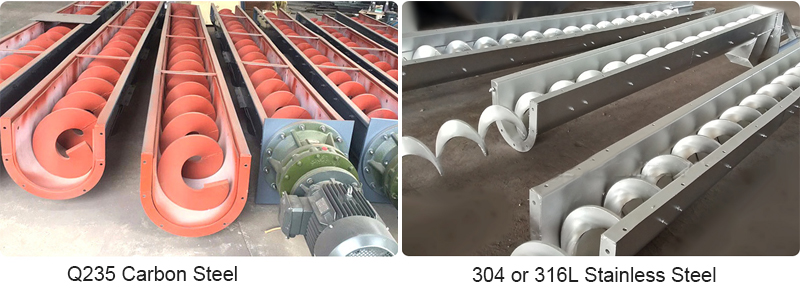

Carbon Steel Shaftless Screw Conveyor: Made of Q235 carbon steel, it is mainly used in industries such as cement, coal, stone and other industries with high wear and no special requirements for materials.

Stainless steel shaftless screw conveyor: made of 304/3316L stainless steel, the welding process is fully welded without gaps, all polished smooth without burrs, double welding inside and outside the inlet and outlet, acid and alkali corrosion resistance, high temperature resistance of 200 ° C, not easy to rust, can prevent material Contaminated in the process of conveying, there is no leakage phenomenon. It is suitable for industries that require hygiene such as food, medicine and chemical industry.

In terms of raw materials, 304 stainless steel will be more expensive than Q235 carbon steel, so the price of stainless steel shaftless screw conveyor will be higher than that of carbon steel.

2. Different designs

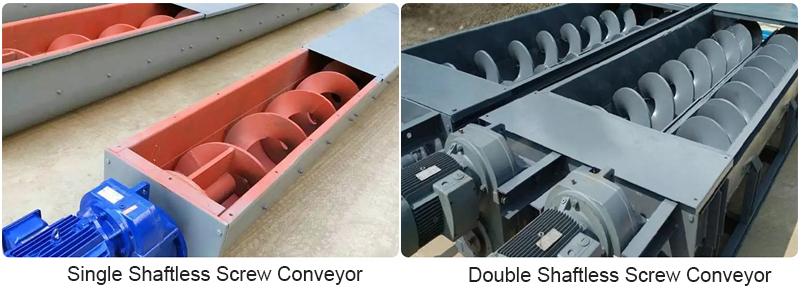

Shaftless screw conveyor is divided into single shaftless and double shaftless screw conveyor

Compared with the single shaft, the double shaftless screw conveyor has the function of stirring and stirring. The rotation directions of the two screw shafts are opposite, which can prevent the material from clogging, and the conveying capacity is 1.5-2 times that of the single shaft. In the consumables and production process, the production cost of double shaftless screw conveyor is of course higher than that of single shaftless screw conveyor.

The above is an introduction to the price of the shaftless screw conveyor. In the selection process, it is necessary to select the appropriate material and design according to the conveyed material, and select the specific model according to the requirements of the conveying volume and length, which can ensure higher production efficiency on the one hand. On the other hand, it will avoid the cost problem caused by wrong selection.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.