Can move large volumes of material quickly and consistently Shaftless design reduces risk of clogging and clogging, harsh environments or applications where materials may be abrasive or corrosive

![]()

![]()

![]()

Price:$750.00-$3,960.00/Set

Consult now and enjoy a 10% discount

Material: 304 stainless steel or 316L stainless steel

Type: Single shaftless/double shaftless

Diameter: 150 - 470mm

Inclination of installation: 0-15° or 0-30°

Length: 0-20mt or 0-30mt

Capacity: from 0.8 mc/h to 45 mc/h

Application: Conveying abrasive or corrosive viscous products such as sludge, pulp, fruit, waste water, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

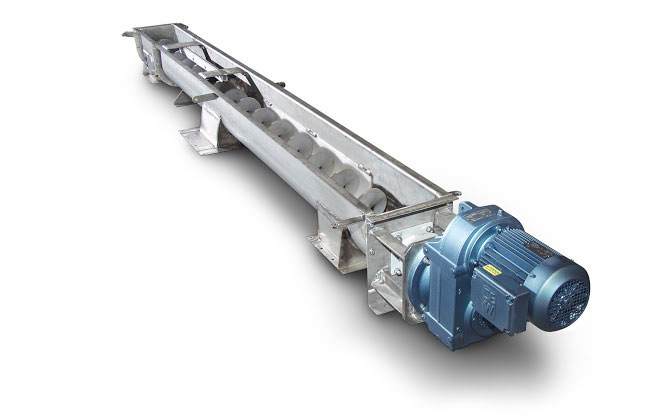

Stainless steel shaftless screw conveyor is mainly made of 304 or 316L stainless steel with no central shaft in the middle. It is suitable for conveying materials with strong viscosity and high water content that are difficult to convey. , concentrated or conditioned sludges, packaged foods, creams or pastes, and wastes from the processing of meat, fish, fruits and vegetables. It is resistant to acid and alkali corrosion, not easy to rust, and avoids the pollution of raw materials. It is a necessary conveying equipment for food, medicine, chemical industry and some waste treatment industries.

Stainless steel shaftless screw conveyors are widely used in industries and applications that require efficient and reliable transportation of large quantities of materials. The shaftless design and stainless steel construction improve efficiency, durability and sanitation, making them ideal for those looking for a cost-effective and reliable material transportation solution A popular choice for businesses with plans. Here are some common applications for these conveyors:

Wastewater Treatment: Typically used in wastewater treatment plants to transport dewatered sludge from the treatment process to storage or disposal facilities. The shaftless design reduces the risk of clogging and clogging, increasing efficiency and reducing maintenance needs.

Food Processing: Used in the food processing industry to convey a variety of materials, including fruit, vegetables, grains and meat. Stainless steel construction ensures food safety and sanitation, and the shaftless design reduces the risk of clogging and clogging.

Mining industry: used to transport materials such as ore, coal and minerals. The shaftless design reduces the risk of clogging and clogging, increasing efficiency and reducing maintenance needs.

Agriculture: Used in agriculture to transport materials such as animal feed, grain and fertilizers. Stainless steel construction ensures durability, and the shaftless design reduces the risk of clogging and clogging.

Chemical Processing: Used in the chemical processing industry to convey a variety of materials, including powders, granules and liquids. Stainless steel construction ensures chemical resistance, and the shaftless design increases efficiency and reduces the risk of clogging and clogging.

No clogging

The shaftless design of the conveyor reduces the risk of jamming and jamming, increasing efficiency and reducing maintenance needs. This can lead to significant cost savings over time.

Improve hygiene

Stainless steel construction ensures hygiene and cleanliness, making it suitable for food processing, pharmaceutical and other applications where cleanliness is critical.

Durability

Stainless steel is a highly durable material that is resistant to corrosion and wear, making it ideal for use in harsh environments or applications where the material may be abrasive or corrosive.

Versatility

DCan be customized to meet application specific needs. They can be designed in different lengths, diameters and angles of inclination to handle a wide variety of materials.

Improve security

The shaftless design of the conveyor reduces the risk of accident or injury with conventional screw conveyors, which may have an exposed rotating shaft.

Improve efficiency

The shaftless design of the conveyor can move more material, increasing efficiency and reducing the need for multiple conveyors.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

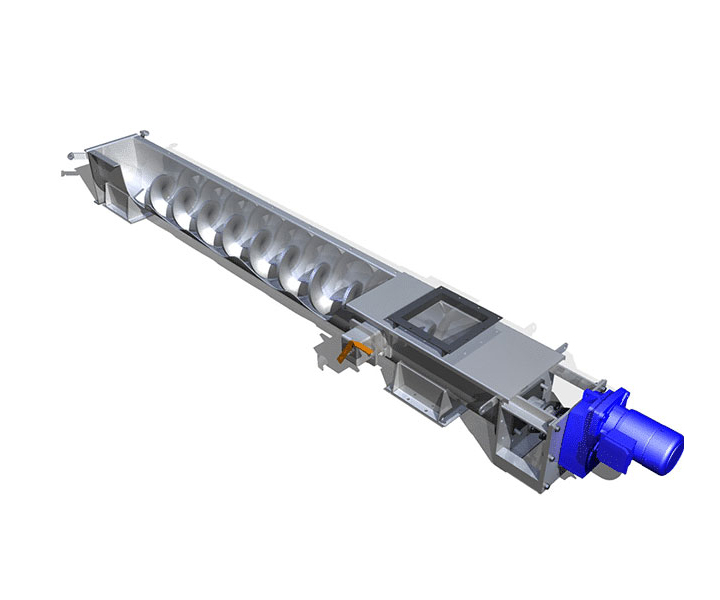

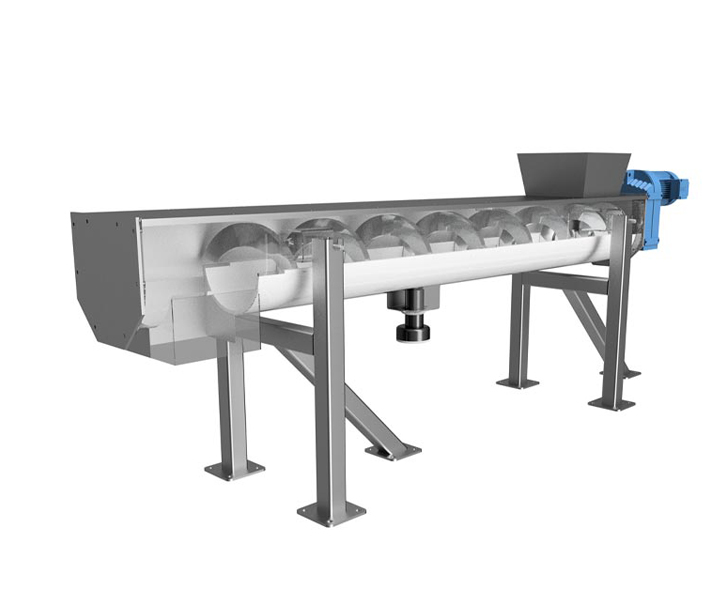

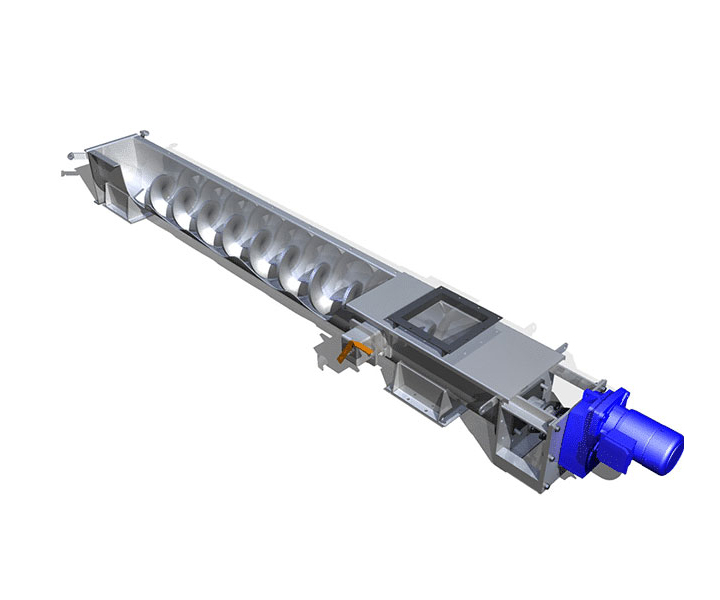

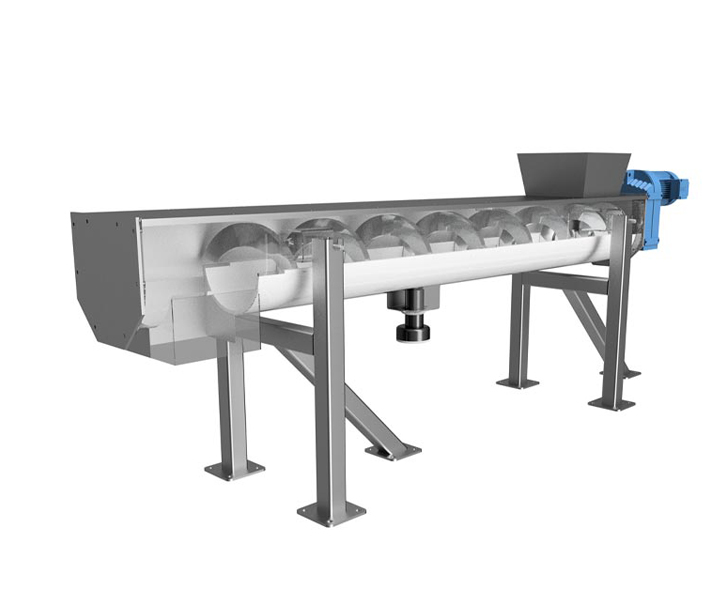

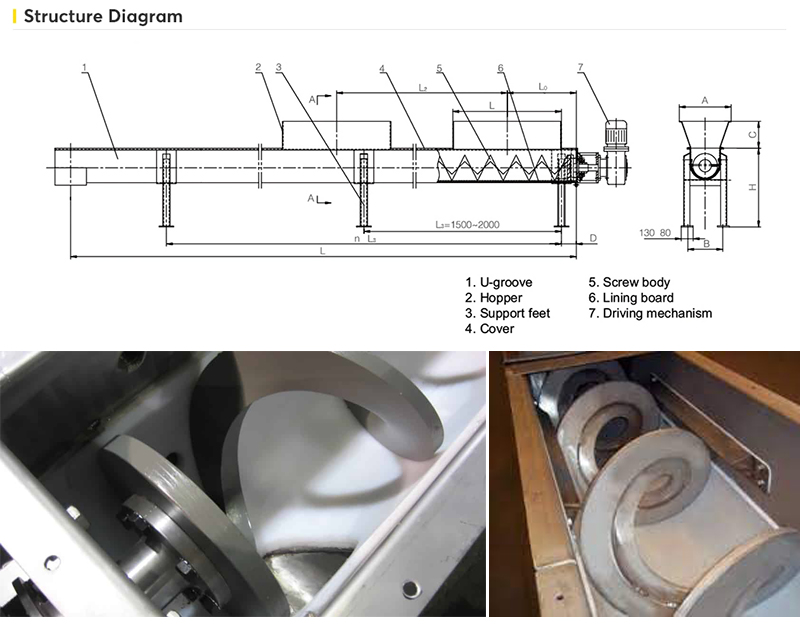

Shaftless screw conveyor is mainly composed of driving device, head assembly, casing, shaftless screw body, tank lining plate, feeding port, discharging port, cover (when necessary), base and so on.

Driving device: Cycloidal pinwheel reducer or shaft-mounted hard-tooth surface gear reducer is used. In the design, the driving device should be set at the end of the discharge port as much as possible, so that the screw body is in a tension state during operation.

Chassis: The chassis is U-shaped or O-shaped, with a rain-proof cover on the upper part, and the material is mainly stainless steel.

Head assembly: there is a thrust bearing, which can bear the axial force generated when conveying materials.

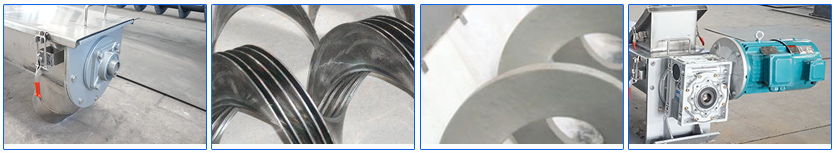

Shaftless spiral body: The material is stainless steel, which is resistant to acid and alkali corrosion, clean and hygienic, and easy to clean.

Tank liner: The material is wear-resistant plastic plate or rubber plate or cast stone plate, etc.

Inlet and outlet: There are two kinds of square and round. Generally, the form of inlet and outlet is determined by the user.

There are many customer cases and testimonials about the benefits of using stainless steel shaftless screw conveyors in various industries and applications. Here is an example of a customer case:

A food processing company in the United States was looking for a more efficient way to transport raw materials from the warehouse to the production area. The company was previously using traditional screw conveyors, but they were experiencing frequent clogs and maintenance issues, which slowed down their production process.

The company decided to invest in stainless steel shaftless screw conveyors to improve their material handling process. The shaftless design of the conveyors reduced the risk of clogs and blockages, improving efficiency and reducing the need for maintenance.

The stainless steel construction of the conveyors ensured hygiene and cleanliness, making them suitable for use in food processing. The conveyors were customized to meet the specific needs of the application, including different lengths and angles of incline to handle a wide range of materials.

After installing the stainless steel shaftless screw conveyors, the company reported significant improvements in their production process. The conveyors reduced downtime, improved efficiency, and reduced the need for manual labor. The company also reported improved hygiene and cleanliness in their production area, which was an important factor in meeting food safety regulations.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.