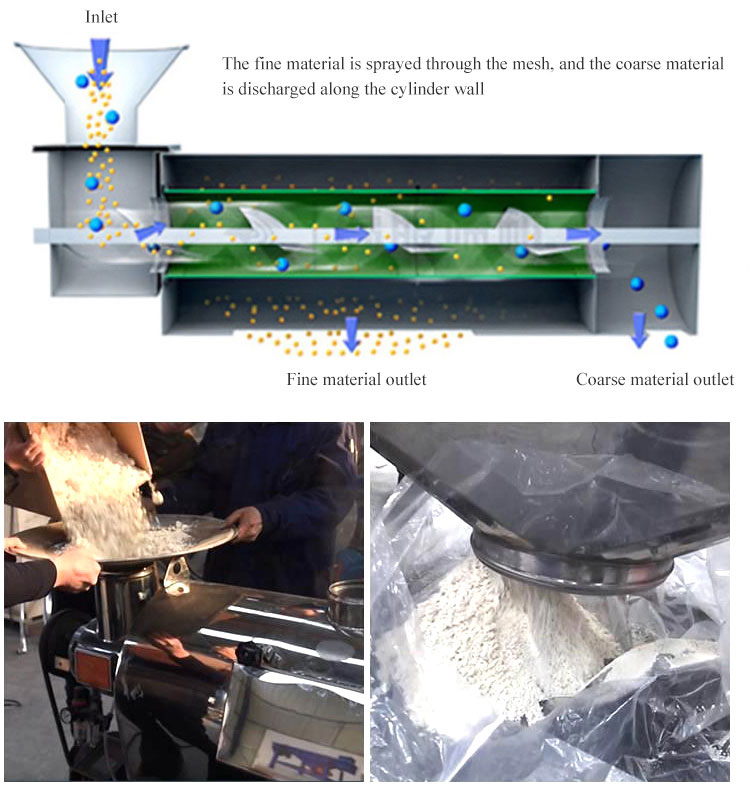

centrifugal sifter is used for high-speed screening of fine powder to remove impurities and oversized agglomerates. This article will introduce the use of centrifugal sifter in detail.

In order to ensure the product quality of processed materials, centrifugal sifter provides three main operating procedures:

Particle Separation: Separation of products with different particle sizes into two fractions, typically in the range of 40 µm to 5 mm.

Safety Screening: Remove foreign matter and debris before products enter the production process, or ensure product quality before filling.

·Adjustment: Separation of foreign matter and adjustment of product bulk density immediately before production or packaging.

It has been successfully applied to 120-180 mesh light calcium, 300 mesh heavy calcium, 400 mesh active calcium, 300 mesh hawthorn powder, 320-500 mesh zinc powder, 500 mesh iron oxide black and other materials, and good screening results have been achieved. The measured screen area is about 1 ton per square meter per hour, the screening accuracy is above 95%, and the air dust content is less than 10mg/m3.

Typical industry applications include:

1. Food industry: flour sieving, ingredient inspection and screening, milk powder screening, baking mix de-agglomeration and final dressing

2. Chemical industry: general fine powder classification, nylon fleece depolymerization, powder depolymerization, powder coating inspection and screening

3. Pharmaceutical industry: check the screening of raw materials and the classification of active ingredients of drugs

| Material | Typical Capacity | Material | Typical Capacity |

| Cocoa powder | 1-70 t/h | Powder coating | 1-30 t/h |

| Fish meal | 1-40 t/h | Expanded silica | 0.5-6 t/h |

| Flour | 1-60 t/h | Hydrated alumina | 1-30 t/h |

| Milk powder | 1-30 t/h | Iron oxide | 1-40 t/h |

| Resin powder | 1-50 t/h | Calcium carbonate | 1-70 t/h |

| Spices | 1-40 t/h | Expanded perlite | 0.25-7 t/h |

| Starch | 1-50 t/h | Plaster | 1-90 t/h |

| Sugar | 1-120 t/h | Mica | 0.25-10 t/h |

The above is the introduction to the use of centrifugal sifter. Centrifugal sifter has a variety of sizes to choose from. The size of the machine is determined by the size of the screen surface. It can handle powder or granules from a few kilograms to more than 90 tons per hour. The output is 5 times that of ordinary vibrating screens. -10 times or higher.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.