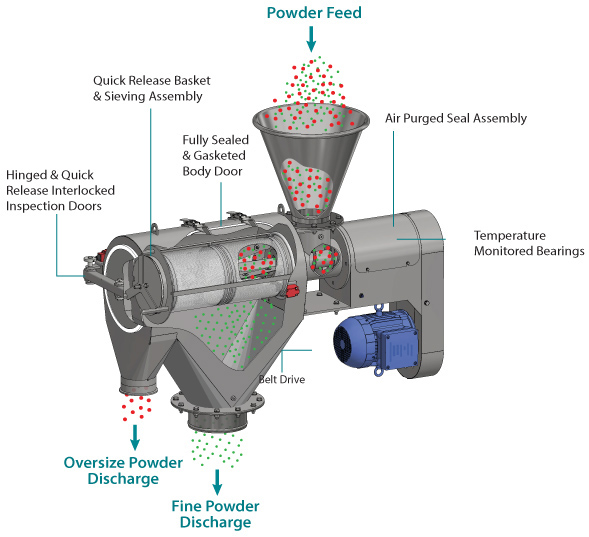

The centrifugal sifter separates particles of different sizes into two product streams, removes the pollutants in the dry powder, and breaks the agglomerates at the same time. This article will introduce the working principle of the centrifugal sifter in detail.

The rotating paddle inside the centrifugal sifter throws the material towards and passes through the static cylindrical screen, the oversized particles are sprayed to the discharge port through the downstream end of the screen cylinder, and the lighter particles are brought to the discharge port together with the paddle. The centrifugal force generated by the leaves is also great for breaking up lumps and agglomerated powders, enabling them to pass through the screen and increasing production. The slurry is mounted on a centrifugal sifter cantilever shaft, eliminating the need for additional bearings and also facilitating cleaning and quick screen changes.

In order to ensure the product quality of the processed materials, centrifugal sifter provides three main operating procedures:

1. Particle separation: Separation of products with different particle sizes into two parts, usually in the range of 40 µm to 5 mm.

2. Safety screening: Remove foreign matter and impurities before the product enters the production process, or ensure product quality before filling.

3. Adjustment: Separate foreign bodies and adjust product bulk density before production or packaging.

As a high-precision screening machine for fine powder, centrifugal sifter has a screening efficiency of 85-95%, the residue on the screen is basically 0 (which is difficult to achieve with ordinary vibrating screens), and the product is 5-10 times that of ordinary vibrating screens.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.