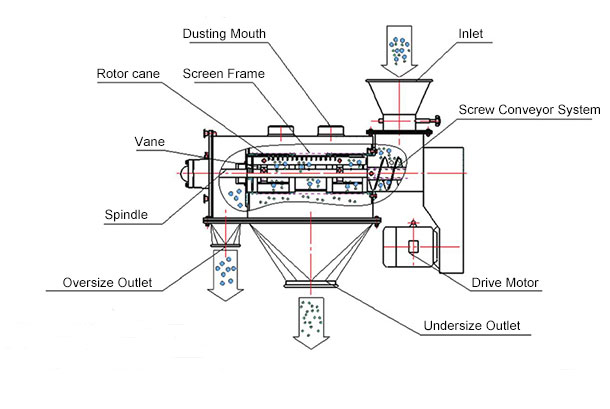

Rotary sifter separates particles of different sizes into two product streams, removes pollutants in dry powder, and breaks up agglomerates at the same time. This article will introduce the working principle of rotary sifter in detail.

The rotating paddle inside the Rotary sifter throws the material to and passes through the static cylindrical screen. The oversized particles are sprayed to the discharge port through the downstream end of the screen cylinder, and the lighter particles are brought to the discharge port together with the paddle. The centrifugal force generated by the leaves is also very suitable for breaking up agglomerates and agglomerated powders so that they can pass through the screen and increase the output. The slurry is installed on the cantilever shaft of the cyclone screen without additional bearings, and it is also convenient for cleaning and quick screen change.

Increase your productivity - the machine achieves high capacities with a small footprint. Its basket is also very easy to remove for cleaning or mesh change

Safeguard the health and safety of your operators - Rotary sieves are extremely quiet and also benefits from a dust-tight body for a clean workplace

Improve your product quality - The rotating paddle blades aid the de-agglomeration of the product

Address:China,Yanjin county forest park gate to the west 1000 meters north road.