Ensures a "screening process" by removing unwanted material and reducing powder handling risks.

![]()

![]()

Price:$900.00-$5,700.00/Set

Consult now and enjoy a 10% discount

Function: Remove unwanted particles from powder and break up clumps

Screen mesh: 80-530 mesh

Screen cylinder perforation size: 0.15-10mm

Processing capacity: 1-15 t/h

Material: carbon steel or stainless steel

Power: 2.2-5.5KW

Application: Removes oversized contaminants or debris from dry powder products. This makes rotary sifters ideal for pre-screening ingredients, often after silos, to remove contaminants from dry powders.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

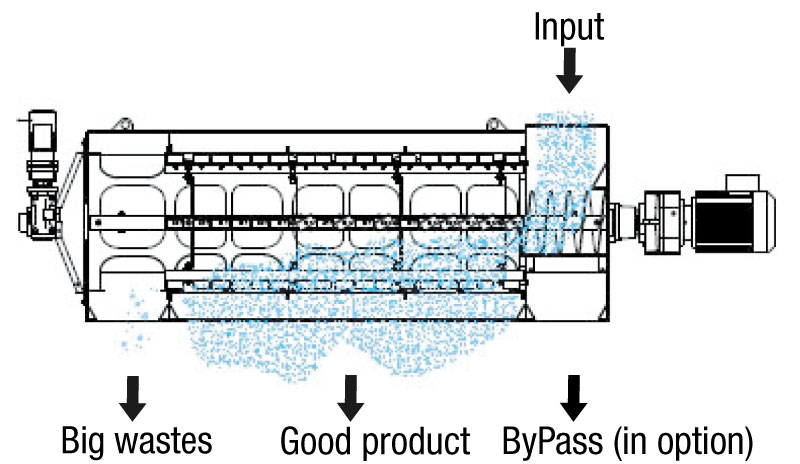

Rotary sifter separates particles of two different sizes by using centrifugal force. Smaller material is passed through a static cylindrical screen by rotating paddles, while oversized particles move along the screen to an outlet at the end of the unit. The centrifugal force generated by the paddles is also excellent for breaking up clumps and agglomerated powders, allowing them to pass through the mesh and increasing throughput, which can vary from more than 90 tons per hour to several kilograms.

The material to be screened is sent to the stationary cylindrical screen by the screw installed on the rotating shaft of the rotary sifter, and the non-contact rotating paddles in the screen press the material on the screen by centrifugal force, break up the soft agglomerates, and pass through the screen. The finely screened material (fine powder) of the mesh is discharged into a collection hopper at the bottom of the machine, and oversized material and hard lumps (which cannot be broken by hand) move down the length of the screen to the screen outlet.

In order to ensure the product quality of processed materials, the rotary sifter provides three main operating procedures:

Particle Separation: Separation of products with different particle sizes into two fractions, typically in the range of 40 µm to 5 mm.

Safety Screening: Remove foreign matter and debris before products enter the production process, or ensure product quality before filling.

Conditioning: Separation of foreign matter and regulation of product bulk density immediately before production or packaging.

rotary sifter working principle

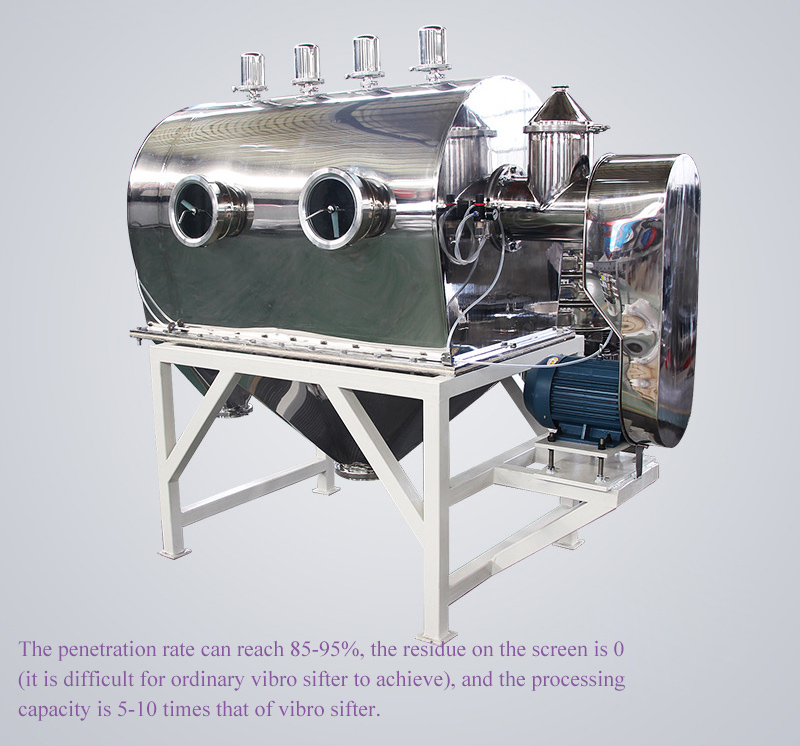

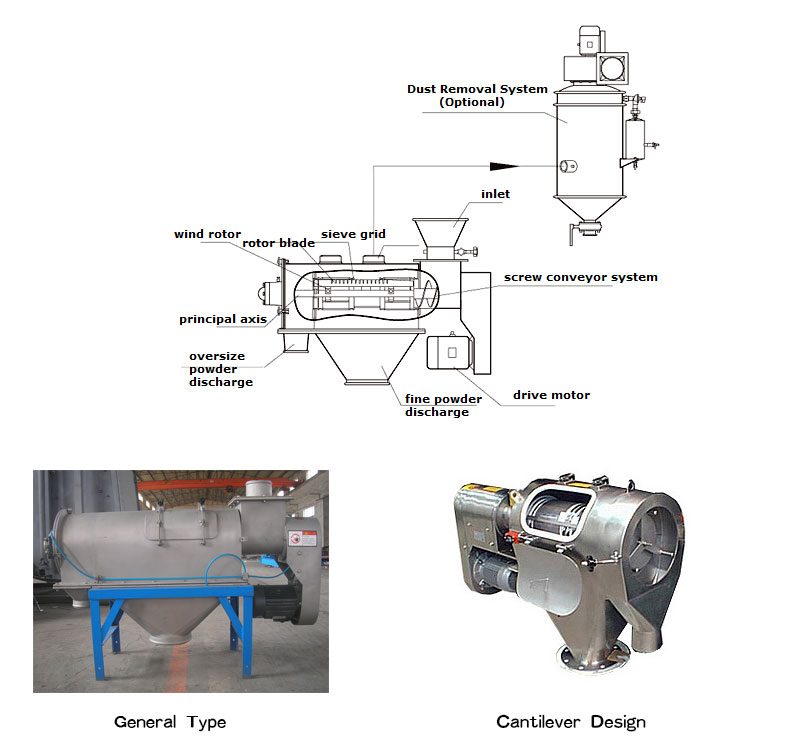

The screen of the rotary sifter is cylindrical and placed in the screen body. The screened material is mixed with the air flow through the conveying system, materialized and then entered into the mesh cylinder. When the material passes through the rotor blades in the mesh cylinder, it is propelled by centrifugal force and cyclone. Therefore, the material can be sprayed through the net and finally discharged from the fine material discharge port, while the material that cannot pass through the net is discharged from the coarse material discharge port along the wall of the net cylinder.

1. Suitable for low bulk density and lightweight products/applications (such as talc, pigments, silica sand, etc.), mesh size 80-500 mesh.

2. The penetration rate can reach 85-95%, the residue on the screen is 0 (it is difficult for ordinary vibro sifter to achieve), and the processing capacity is 5-10 times that of vibro sifter.

3. Provide a completely closed and dust-free environment without dust pollution.

4. The cantilever shaft is designed for easy cleaning and quick screen change.

Titanium dioxide rotary sifter

Pharmaceutical powder rotary sifter

| Model | Material | Power | Application |

| WQS18-65 | Q235A | 2.2KW | Screening below 500 mesh |

| SUW304 | |||

| WQS30-100 | Q235A | 4KW | |

| SUW304 | |||

| WQS50-130 | Q235A | 5.5KW | |

| SUW304 |

The following table shows you the difference between rotary sifter and other sifters:

| Comparison item | Rotary Sifter | Vibratory Sifter |

| Principle | Generated centrifugal force separates particles according to particle size | Vibration is used to separate particles according to particle size by means of fixed openings in the screen |

| Application | Low bulk density and light weight products, fine powders that are easy to agglomerate (such as talc, pigments, silica sand, etc. | powder, granule or liquid |

| Throughput | High-capacity continuous screening, the processing capacity is 5-10 times that of other sieves. | Good for small batch processing or lower throughput rates. |

| Custom options | to customize with different screen sizes and configurations, materials of construction, motor and drive configurations, and other features | May have more limited customization options, or may require more specialized equipment to meet specific application requirements |

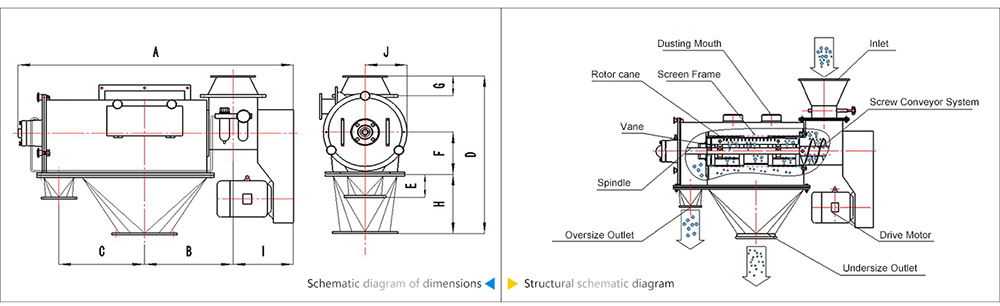

| Model | A | B | C | D | E | F | G | H | I | J |

| WQS18-65 | 1430 | 460 | 420 | 1005 | 135 | 230 | 250 | 330 | 340 | 210 |

| WQS30-100 | 1845 | 655 | 766 | 1240 | 320 | 285 | 300 | 350 | 380 | 290 |

| WQS50-130 | 2230 | 870 | 790 | 1775 | 280 | 515 | 150 | 660 | 400 | 485 |

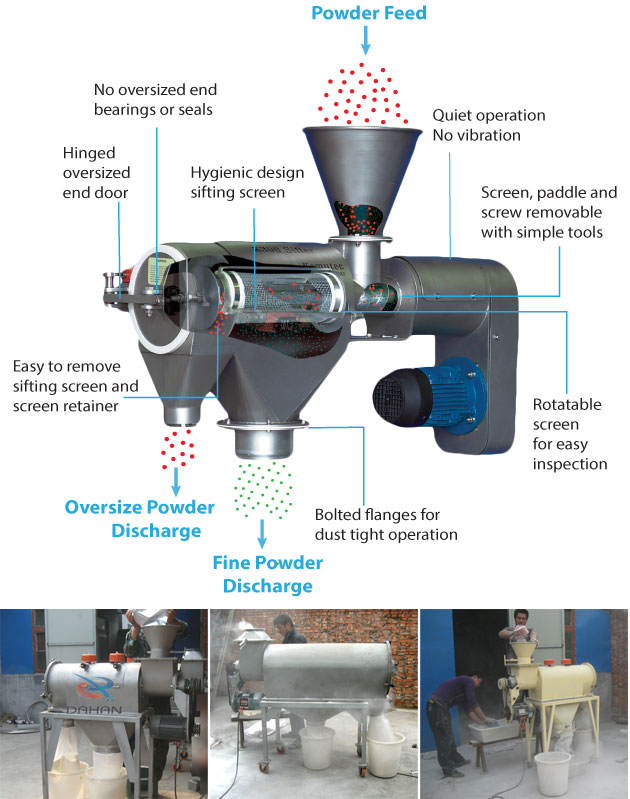

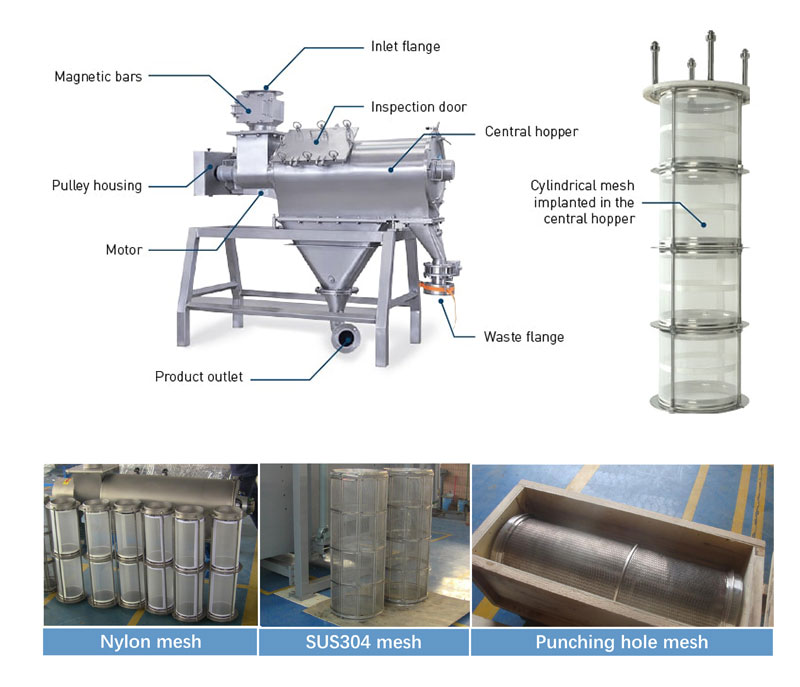

1. Screen or Sieve: The screen or sieve is a cylindrical or drum-shaped mesh screen that rotates horizontally and separates the particles based on their size. The size and configuration of the screen can be customized to meet specific particle size distribution requirements.

2. Drive Mechanism: The drive mechanism consists of an electric motor and a gearbox that rotates the screen at a controlled speed. The speed of rotation can be adjusted to optimize the efficiency of particle separation.

3. Inlet and Outlet: The inlet and outlet are openings on opposite ends of the sifter. The material to be sifted is fed into the sifter through the inlet, and the separated particles are discharged through the outlet.

4. Housing: The housing is a rigid frame that supports the screen, drive mechanism, and other components. The housing is typically made of stainless steel or other durable materials.

5. Bearings: The bearings support the rotating screen and allow it to rotate smoothly. The bearings are typically located at each end of the screen.

6. Discharge Mechanism: The discharge mechanism is a device that removes the separated particles from the screen and discharges them through the outlet. The discharge mechanism can be pneumatic or mechanical, depending on the specific application.

Rotary sifters can be customized to meet specific industrial applications. Some common customization types include:

1. Screen Size and Configuration: The size and configuration of the screen can be customized to meet the specific particle size distribution required for the application. Screens can be made with different size openings, materials, and shapes, such as round, square, or rectangular.

2. Screen Material: The screen material can be customized to meet specific application requirements, such as corrosion resistance, abrasion resistance, or temperature resistance. Common screen materials include stainless steel, brass, plastic, and nylon.

3. Construction Materials: The construction materials of the sifter can be customized to meet specific requirements for durability, corrosion resistance, or sanitation. Common construction materials include carbon steel, stainless steel, and aluminum.

4. Motor and Drive Configuration: The motor and drive configuration can be customized to meet specific requirements for power, speed, and efficiency. Options for customization include variable speed drives, explosion-proof motors, and air-powered motors.

5. Inlet and Outlet Configuration: The inlet and outlet configuration can be customized to meet specific requirements for product flow, loading, and unloading. Options for customization include top, bottom, or side inlet and outlet configurations, as well as pneumatic or mechanical discharge mechanisms.

6. Sanitary Features: Sanitary features can be added to rotary sifters to meet specific requirements for cleanliness and hygiene in food, pharmaceutical, and other sanitary applications. Sanitary features may include smooth, easy-to-clean surfaces, quick-release clamps for easy disassembly and cleaning, and FDA-approved gaskets and seals.

There are several types of rotary sifters, different types of rotary sifters are designed to meet different requirements, and can be customized to meet specific application needs:

1. High-Capacity Rotary Sifters: These sifters are designed for large-scale industrial applications that require high throughput rates. They typically have larger screens and more powerful motors than other types of sifters.

2. Low-Profile Rotary Sifters: These sifters are designed to fit in tight spaces and have a low profile. They are often used in applications where space is limited.

3. Batch Rotary Sifters: These sifters are used for small batch processing. The material is loaded into the sifter, and the centrifugal force separates the particles based on their size.

4. Continuous Rotary Sifters: These sifters are designed for continuous processing of large quantities of material. The material is fed into the sifter, and the centrifugal force separates the particles based on their size as it flows through the sifter.

5. Sanitary Rotary Sifters: These sifters are designed for use in food, pharmaceutical, and other sanitary applications where cleanliness and hygiene are critical. They are typically made of stainless steel and have smooth surfaces to prevent bacteria buildup.

6. Dual-Drive Rotary Sifters: These sifters have two motors and can be used to process difficult-to-sift materials or to achieve greater control over the particle size distribution.

| Food & Dairy | Chemical | Mineral | |||

| Material | Typical Capacity | Material | Typical Capacity | CALCIUM CARBONATE | 1-70 TPH |

| COCOA POWDER | 1-70 TPH | CALCIUM STEARATE | 1-30TPH | EXPANDED PEARLITE | 0.25-7 TPH |

| FISH MEAL | 1-40 TPH | EXPANDED SILICA | 0.5-6 TPH | GYPSUM | 1-90 TPH |

| FLOUR | 1-60 TPH | HYDRATED ALUMINA | 1-30 TPH | MICA | 0.25-10 TPH |

| GROUND COFFEE | 1-30 TPH | IRON OXIDE | 1-40 TPH | ||

| LACTOSE | 5-300 GPM | LATEX | 5-200 GPM | ||

| (20-1850 LPM) | (20-900 LPM) | ||||

| MILK POWDER | 1-30 TPH | PAPER FIBER | 5-400 GPM | ||

| NON-DAIRY CREAMER | 1-50 TPH | (20-1800 LPM) | |||

| SPICES | 1-40 TPH | PIGMENTS | 1-40 TPH | ||

| STARCH | 1-50 TPH | POLYMER BEADS | 1-250 GPM | ||

| SUGAR | 1-120 TPH | (20-1150 LPM) | |||

| TOFU | 5-200 GPM | POWDER COATINGS | 1-30 TPH | ||

| (20-900 LPM) | TiO2 SLURRY | 5-250 GPM | |||

| DISTILLERY SPENT GRAIN | 10-150 GPM | (20-1150 LPM) | |||

Address:China,Yanjin county forest park gate to the west 1000 meters north road.