Polyethylene glycol for Vibrating screen is a vibrating screen that uses polyethylene glycol material as a screen mesh. Vibrating screen is a kind of equipment commonly used for solid particle separation, screening and filtration. Vibration causes materials to produce continuous jumping motion on the screen surface, thereby achieving separation of different particle sizes. The polyethylene glycol vibrating screen uses a screen mesh made of polyethylene glycol material, which has the characteristics of high temperature resistance, corrosion resistance, and oxidation resistance. It is suitable for some particle screening occasions with special requirements.

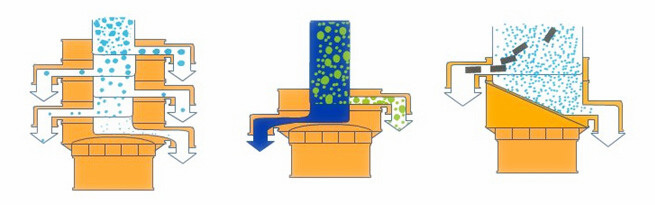

Polyethylene glycol for vibrating screen is mainly composed of vibration motor, screen mesh, screen box, vibration spring and base. The polyethylene glycol for vibrating screen uses a vibration motor to drive the screen box to vibrate. Under the action of vibration, the material reciprocates on the screen surface, thereby screening out materials of different particle sizes. The materials on the screen are divided into multiple levels with different particle sizes. Materials with larger particle sizes stay on the upper layer, while materials with smaller particle sizes fall to the lower layer through the screen, thereby achieving classification.

1. Screening: Polyethylene glycol for vibrating screen can screen materials according to their particle size to meet the production needs of products with different particle size requirements;

2. Classification: The screen is divided into multiple levels according to different mesh sizes, and materials can be classified according to particle size to obtain products with uniform particle size;

3. Removal of impurities: The high-efficiency filtration function of the screen can effectively remove impurities and improve the quality and purity of the product.

Polyethylene glycol for vibrating screens are widely used in many industries, such as:

1. Chemical industry: used to screen granular and powdery chemical raw materials, such as plastic particles, rubber particles, etc.;

2. Grain processing industry: used to screen grain, rice, flour and other grain raw materials to ensure product quality;

3. Pharmaceutical industry: used for fine screening of pharmaceutical materials to ensure drug quality; 4. Metallurgical industry: used for screening and grading of mineral processing, coal and other materials; 5. Research institutions: used for screening and grading scientific research samples.

1. High screening efficiency: The polyethylene glycol for vibrating screen uses an efficient vibration motor with large amplitude and high screening efficiency, which can greatly improve production efficiency;

2. Reasonable mesh design: Reasonable mesh design and uniform mesh size can achieve more accurate screening;

3. Easy maintenance: The vibrating screen has a simple structure, and each component can be disassembled and replaced for easy maintenance;

4. Long screen life: The screen is made of wear-resistant and high-temperature-resistant materials and has a long service life;

5. Reduce dust generation: The polyethylene glycol for vibrating screen is equipped with a sealing device, which can effectively reduce dust generation and improve the working environment.

To sum up, the polyethylene glycol for vibrating screen is a vibrating screen used for powder screening and classification. It has the advantages of high efficiency, accuracy, durability and easy maintenance. It is widely used in multiple industries to increase production efficiency and improve product quality.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.