Vibrating screening powder machine is a common solid-liquid separation equipment, widely used in chemical, food, pharmaceutical and other industries. In order to improve the separation efficiency and service life of the vibrating sieving machine, it is often necessary to add some additives. MES Powder is a commonly used additive, which will be introduced in detail below.

MES Powder is a surfactant with good wetting, dispersing and emulsifying properties, and is often used in the manufacture of detergents, detergents and other products. When it is necessary to sieve MES Powder, the vibrating screening machine can play a very good role. The equipment disperses the powder material on the screen through the vibration force, so as to realize the separation of particles of different particle sizes. At the same time, MES Powder for Vibrating Screening Machine has efficient screening effect and good powder handling capacity, which can improve production efficiency and product quality.

When using a vibrating screening machine to sieve MES Powder, it is necessary to select the appropriate sieve size and vibration force according to actual needs to ensure that the required particle size requirements are met. In addition, it is also necessary to pay attention to the maintenance of the equipment, regularly clean the screen and check the working status of the equipment to ensure the normal operation of the equipment and prolong the service life.

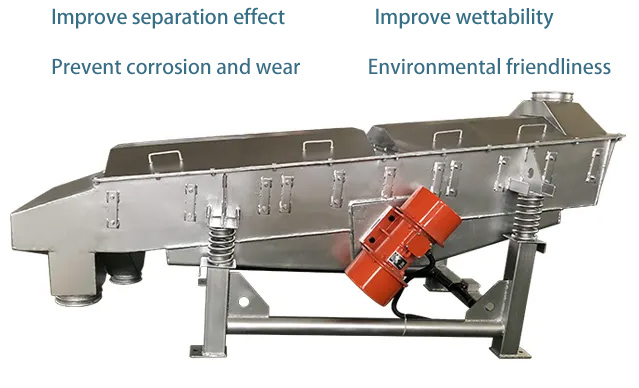

The use of MES Powder for Vibrating Screening Machine has the following advantages:

1. Improve separation effect: MES Powder can reduce the surface tension between dust particles, making it easier to disperse and separate. The vibrating screening machine can quickly separate the solid particles on the sieve through the high-speed vibrating sieve, and adding MES Powder can make the dust particles pass through the sieve holes more easily, improving the accuracy and efficiency of the entire screening process.

2. Improve wettability: For some materials with high water content, MES Powder can improve the contact between the material and the vibrating screen, reduce the adhesion of the material on the screen, and reduce the adhesion and Blockage phenomenon, improve screening effect.

3. Prevent corrosion and wear: The screen and mesh of the vibrating powder screening machine are generally made of metal materials, which are prone to corrosion and wear under long-term vibration and friction. MES Powder can form a protective film to reduce the erosion of the metal screen and prolong the service life of the vibrating screening machine.

4. Environmental friendliness: MES Powder has high stability in aqueous solution, is easy to decompose and degrade, and will not pollute the environment. At the same time, MES Powder has good solubility and biodegradability, and is safe and harmless to staff and equipment.

There are also some precautions in the application of MES Powder. First of all, it is necessary to pay attention to controlling the concentration of additives during use. Excessive concentration may have a negative impact on the screening effect. Secondly, it is necessary to choose the appropriate type and specification of MES Powder to meet the specific operation requirements. Finally, it should be adjusted and optimized according to the actual application to obtain the best separation effect.

In short, MES Powder has many advantages as an auxiliary agent for vibrating screening powder machines, which can improve the separation effect, improve wettability, prevent corrosion and wear, and be environmentally friendly. In practical application, it should be selected and controlled reasonably to improve the working efficiency and life of the vibrating powder sifter.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.