Vibrating screening machine is a commonly used vibrating screening equipment, which is mainly used for screening and grading operations of powdery and granular materials. In the food industry, stevioside is a natural non-nutritive high-intensity sweetener, which is widely used in diabetic food, low-sugar food and health food. In order to ensure the quality of stevioside, the vibrating screening machine plays an important role in the production of stevioside.

For the vibrating screening machine, it is mainly used for sieving and grading solid materials, and stevioside is a powdery material, so it can be sieved and classified by a vibrating screening machine. Stevioside powder is a fine powder made by crushing stevioside crystals, and the requirement of fineness is very important for the use effect of stevioside.

1. Efficient impurity removal: During the production process, stevia will be mixed with some impurities, such as leaf fragments, fibers, etc. The vibrating screen can effectively screen out these impurities.

2. Particle size classification: The particle size of stevia will affect its dissolution rate, taste, etc. The vibrating screen can achieve fine grading of stevia by replacing screens with different apertures.

3. Improve the product quality of stevia: Through screening, impurities in stevia can be removed, and the quality of the product can be improved.

The use steps of stevioside for vibrating screening machine: First, put the stevioside into the feed port of the vibrating sieving machine. Then, the sieve starts to move through the vibrating device, which causes the material to vibrate on the sieve and sieve according to the size of the particles. Smaller particles pass through the screen, while larger particles are blocked by the screen. In this way, stevioside can be separated and classified according to different particle sizes.

The function of stevioside for vibrating screening machine: The vibrating sieving machine adopts a high-efficiency oscillator. By continuously changing the vibration direction and frequency of the sieve frame, the stevioside powder forms a throwing motion at different angles on the sieving surface, thereby expanding the sieving area and improving the sieving efficiency. At the same time, the vibrating screening machine can also adjust the vibration force and vibration frequency according to production needs to meet the production of stevioside with different fineness requirements.

Vibrating screening machine has excellent impurity removal effect in stevioside production. Since stevioside crystals are needle-like or flake-like, they tend to gather together to form clumps, often with impurities. The vibrating screening machine generates shear force and friction force between the stevioside particles through high-frequency vibration, so that they are separated from each other, and then impurities are separated from the stevioside powder. This improves the purity of stevioside and ensures the quality of its products.

The vibrating screen is made of high-quality stainless steel, which is wear-resistant, corrosion-resistant, and easy to clean. In the production of stevioside, the vibrating screening machine avoids metal pollution and ensures the safety and sanitation of stevioside products.

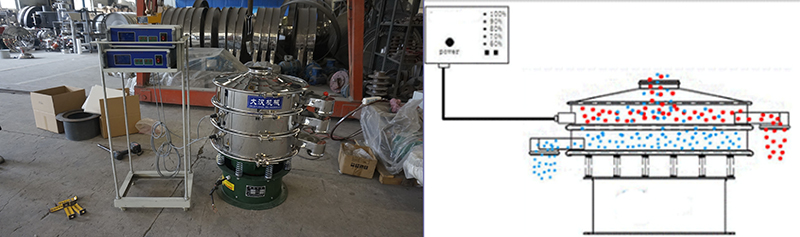

Ultrasonic vibrating screen: An ultrasonic vibration system is added to the traditional vibrating screen. Ultrasonic vibration can improve the screening effect, especially suitable for the screening of fine particles and sticky materials.

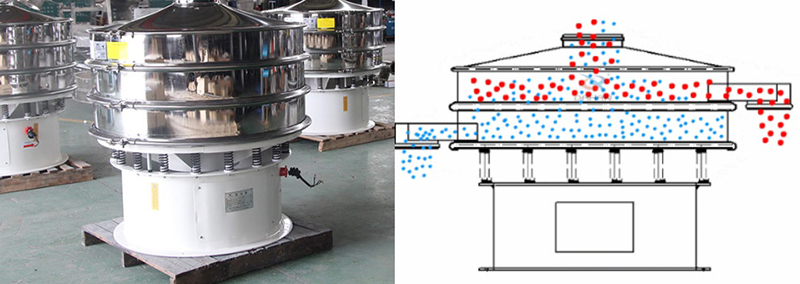

Rotary vibrating screen: It adopts rotary vibration mode, and screens particles through rotary motion and vibration. It is often used for the screening of dry powder granular materials. It has the advantages of high efficiency, large processing capacity, and the ability to quickly separate particles. It is suitable for occasions that require a large amount of granular materials to be screened.

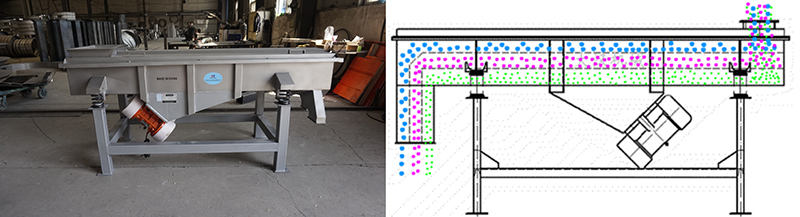

Linear vibrating screen: It adopts linear vibration mode, and the particles move linearly on the screening surface. It is suitable for the screening of fine particles and medium-coarse particles. It has a simple structure, stable operation, and easy maintenance. It is suitable for occasions with high requirements for screening efficiency and product particle size.

| Features | Ultrasonic vibrating screen | Rotary vibrating screen | Linear vibrating screen |

| Screening accuracy | Highest | High | Medium |

| Processing capacity | Relatively small | Large | Large |

| Applicable materials | Ultrafine powder, sticky materials | Various materials | Material with larger particles |

| Structural complexity | High | Medium | Low |

| Price | High | Medium | Low |

1. Food industry: Stevioside is used as a food additive, which can replace sugar or other artificial sweeteners, and is used to produce low-calorie, low-sugar, and low-carbohydrate foods, such as candy, beverages, ice cream, etc.

2. Medicines: Stevioside is also used in the production of medicines to make oral liquids, cough syrups, vitamin tablets, etc., to improve the taste and ease of taking medicines.

3. Health products: Stevioside is often added to health products to make health products with better taste, such as vitamin tablets, dietary supplements, etc.

All in all, vibrating screening machines play an important role in stevioside production. It can effectively improve the fineness of stevioside, separate impurities and improve product quality. At the same time, the vibrating screening machine also has the characteristics of wear resistance, corrosion resistance and easy cleaning, making it more safe and hygienic in the production of stevioside. Through the use of vibrating screening machines, the production process of stevioside has been improved, providing strong support for the development of the stevioside industry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.