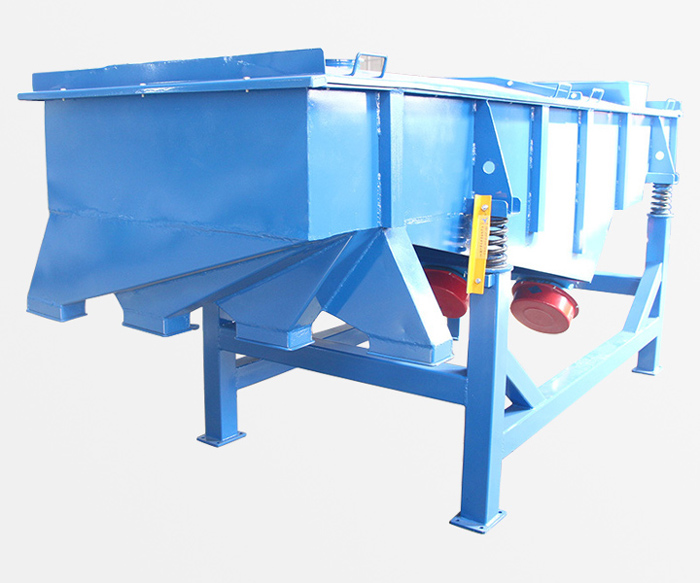

Vibrating screen machine is a common solid screening equipment, which screens materials through vibration force, and can separate and classify coarse, medium and fine materials. Tire powder is the product of waste tires after treatment, which has a wide range of applications, such as fillers, rubber products, etc.

The design principle of the vibrating screen is based on vibration mechanics. Through the action of high-frequency vibration and screen, materials with different particle sizes can be effectively separated. Tire powder usually has different particle sizes, therefore, it can be screened according to different particle sizes by putting the tire powder into a vibrating sieving machine.

Tire powder for vibration screening machine has the following advantages: 1. Efficient: The vibrating sieving machine can quickly separate tire powder into particles of different sizes to improve production efficiency. 2. Precise: The vibrating screening machine can adjust the vibration frequency and amplitude according to the needs to precisely control the separated particle size. 3. Environmental protection: By converting waste tires into tire powder, environmental pollution can be reduced and sustainable resources can be provided for reuse.

Application of tire powder for vibration screening machine: 1. Particle size classification: Tire powder usually has different particle sizes, which can be classified according to particle size by vibrating sieving machine. According to needs, different screens and vibration parameters can be set to achieve precise particle size separation. This classification can meet the needs of different industries for particle size requirements, such as rubber products, construction materials, etc. 2. Reconstitution and mixing: Tire powder can be mixed with other materials to prepare new products. Vibrating sifters can help mix tire powder of different particle sizes with other granular materials, ensuring mix uniformity and quality. 3. Quality inspection: Vibrating sieving machine can be used for quality inspection of tire powder. The quality and uniformity of the tire powder can be assessed by placing the tire powder in a vibrating sieving machine and observing the particle size distribution during separation. 4. Powder recovery: In some processes, tire powder may generate too much powder. Vibrating sieving machines can be used to recover these powders so that they can be reused. Through sieving and separation, the fine powder is separated from the larger particles, and the utilization efficiency of resources is improved. 5. Packaging of powdery materials: The vibrating sieving machine can use the products with the same particle size after screening the tire powder for the packaging of powdery materials. Through the screening process of the vibrating screening machine, it can ensure that the packaged products have consistent particle size and quality, and improve the appearance and market competitiveness of the products.

When using a vibrating sieving machine, you also need to pay attention to the following points: 1. Cleaning: Regularly clean the screen and other parts of the vibrating screen to maintain its normal operation. 2. Maintenance: Do a good job in the daily maintenance of the equipment to prolong the service life. 3. Safety: When operating the vibrating screening machine, follow the relevant safety operating procedures to avoid accidents.

To sum up, the vibrating screen has a wide range of applications in the field of tire powder screening. It can screen and classify tire powder according to different particle size requirements, which improves the utilization value of tire powder; at the same time, it has the advantages of high efficiency, precision, and environmental protection, which can effectively improve screening efficiency and product quality, and reduce manual operations and running costs. Therefore, the vibrating sieving machine has become an indispensable and important equipment in the tire powder processing process.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.