The iron ore vibrating screen is a kind of classification and impurity removal equipment, usually composed of a vibrator, a screen surface, a bottom frame and a discharge port. The iron ore vibrating screen can effectively remove impurities in the material and classify the material. According to the size of the sieve hole, the material can be divided into different meshes. This article will analyze the impurity removal, classification and mesh number of iron ore vibrating screen.

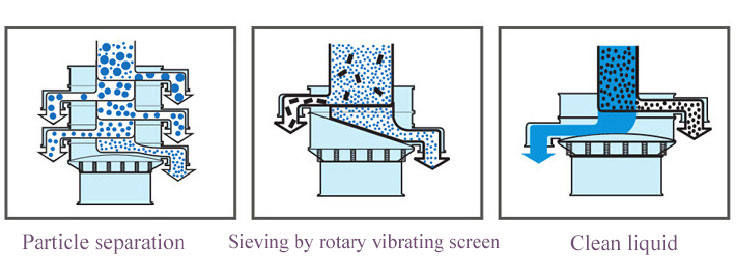

First of all, the iron ore vibrating screen is mainly used to remove impurities in the material, such as sponge iron, slag, slag steel, etc. The iron ore vibrating screen uses the high-frequency vibration generated by the vibrator to vibrate the material on the screen surface forward, while the impurities are difficult to pass through the screen holes due to factors such as small size and low density, so they are removed. Therefore, impurity removal is one of the most basic functions of the iron ore vibrating screen.

Secondly, the iron ore vibrating screen can also divide the material into different grades. When the material moves on the screen surface, the material will form two layers, the upper layer and the lower layer. The upper material falls into the lower layer through the sieve hole, while the lower layer material is screened out through the sieve hole. According to the size of the sieve hole, the material can be divided into multiple grades to meet the needs of different fields.

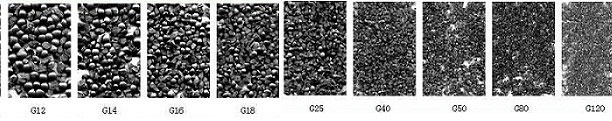

Finally, the iron ore vibrating screen can also classify the mesh of the material according to the size of the screen hole. The mesh number refers to the number of particles of a certain particle size sieved through the standard sieve, and refers to the number of materials with the same particle size that pass through the sieve. The mesh size of the iron ore vibrating screen is determined by the mesh size, usually the smaller the mesh size, the higher the mesh number, and the larger the mesh size, the smaller the mesh number.

Iron ore vibrating screen is a kind of classification and impurity removal equipment, which is mainly used for screening powdery materials such as iron ore. The high-frequency vibration generated by the vibration makes the material form two layers, the upper layer material falls into the lower layer through the sieve hole, and the lower layer material is screened out through the sieve hole, so as to realize the material classification and impurity removal. In addition, the mesh size of the iron ore vibrating screen is also determined according to the mesh size, the smaller the mesh size, the higher the mesh number, and the larger the mesh size, the smaller the mesh number.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.