circular vibrating screen

circular vibrating screen circular vibrating screen separator

circular vibrating screen separator multi-layer circular vibrating screen separator

multi-layer circular vibrating screen separator Ultrasonic circular vibrating screen

Ultrasonic circular vibrating screen Plastic circular vibrating screen

Plastic circular vibrating screen

For separation, peeling and classification processes in dry and wet applications in the pharmaceutical, chemical, food and cement industries

![]()

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Diameter: 400mm、600mm、800mm、1000mm、1200mm、1500mm、1800mm、2000mm

Feeding size: Less than 30mm

Capacity: 100-3300kg/h

Power: 0.18-2.2KW

Material: carbon steel, stainless steel, plastic

Application: For screening wet and dry materials, can remove oversize and contamination, suitable for a variety of applications including screening pharmaceutical powders, various food powders and powder coatings

Commitment:

Circular vibrating screen is suitable for mass production of industrial screening, it can be used for the separation process of solids in liquid, for separation of different particle sizes in the same product, for safety screening to eliminate foreign matter, for particle homogenization, etc.It allows a throughput of 100 to 3,300 kg/h, depending on the product, mesh size and feed flow of the machine. It is suitable for sieving from 36 microns to 25 mm.

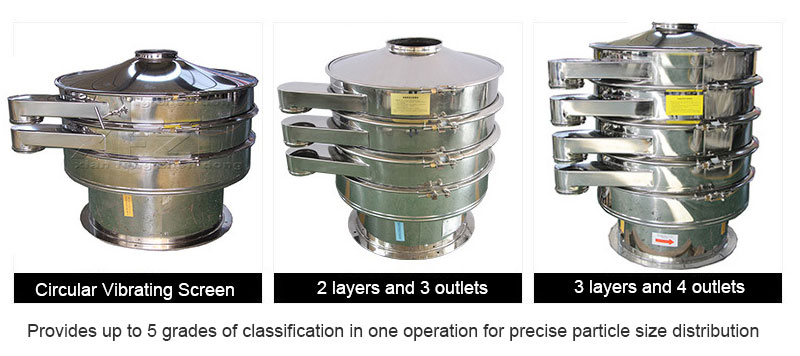

Circular vibrating sieve can separate up to 6 different specifications of products according to up to 5 layers of sieves at a time, the diameter of the machine: 400, 600, 800, 1000, 1200, 1500 or 1800 mm, different sizes and options are available, to meet your screening requirements.

Impurity Removal: Used to remove broken or undersized products such as lumps and other contaminants for final quality checks.

Classification: Precisely separates particles of different sizes from the product so that the final material is classified into different sizes. This is usually achieved by passing the product through a grid of up to 5 different aperture sizes.

Solid-liquid separation: It can quickly remove insoluble solid substances in various slurries, and can quickly discharge slag.

Circular vibrating screen can be used for single-layer powder removal, multi-layer particle size classification, and solid-liquid separation and filtration. It is widely used in the screening and filtration of granules, powder, mucus and other materials. It is widely used in industry and is suitable for industry and food industries. , metallurgical industry, etc., is a multi-purpose general screening equipment.

Our can guide you through our different configurations and models to get the best solution for your application needs.

Circular Vibratory Sifter

It enables sieving on finer meshes (down to 20 microns) without any blocking

Ultrasonic Vibrating Screen

Allows separation accuracy down to 20µm (#635 mesh) so that sieves do not clog

Circular Tumbler Screen

Controlled screening, classification and dedusting of dry, powdered, granular products

Direct Discharge Sifter

Used for screening powders and granules in large batches, suitable for large output and coarse material screening

Filter Screen

It can effectively handle solid-mixed materials and quickly realize solid-liquid separation

High Frequency Vibrating Screen

Can quickly achieve solid-liquid separation, suitable for viscous slurries

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

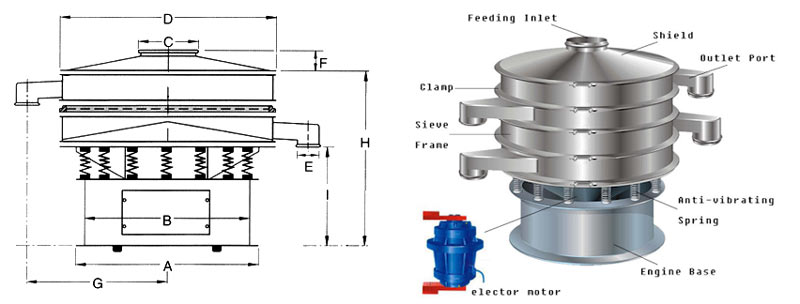

Circular vibrating screen uses a vertical vibration motor as the excitation source. The eccentric hammers at the upper and lower ends of the vibration motor convert the rotary motion into horizontal, vertical and inclined three-dimensional motion, and transmit it to the screen surface of the circular vibrating screen. According to different screening requirements, the material Through 1-5 layers of screens with different mesh numbers, in the process, the cleaning devices located under the screens of each layer continuously hit the screens, so that the materials can be sieved smoothly, effectively avoiding the problem of material clogging, and the materials with different mesh numbers pass through. The screens with the corresponding meshes of each layer are discharged through the outlet set at each layer to realize sieving or filtration.

improve product quality

Accurately removes oversized contaminants and is ideal for inspection and screening of your feed on the primary side of your production facility to finished products on the secondary side.

multi-layer grading

On each circular vibrating screen, you can install 1 to 4 separation stages, resulting in 2 to 5 product gradings.

higher throughput

Available in diameters from 16" (400mm) to 79" (2540mm), handling capacity from 100-3300kg per hour, pending on the product, the mesh opening size and the feed flow to the machine.

easy to clean

The screen can be quickly disassembled for cleaning or replacement, and a cleaning device is installed under the screen to prevent the screen from clogging when screening fine powder and other difficult-to-screen materials.

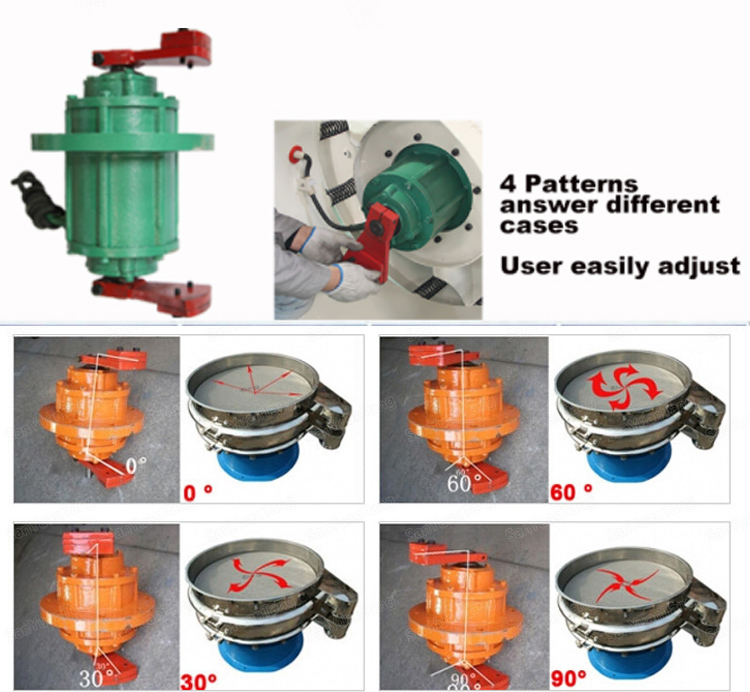

easy to adjust

The vibratory motion of the screen runs horizontally and vertically, and can be adjusted in both directions, making it easy to quickly change the vibratory motion and thus the behavior of the material to be screened.

Small footprint

Simple in structure and small in size, it can be easily installed into the production line, providing optimum screening capacity without requiring excessive floor space.

All our circular vibrating screens and separators comply with international safety, quality and hygiene standards and regulations. We offer a wide range of diameters from 15" (400mm) to 78" (2000mm) with single or multiple screens Our team can guide you through our different configurations and models to get the best fit for your application needs best solution.

1. Gate-type circular vibrating screen: a product improved on the basis of the ordinary type, which is usually used to screen ultra-light and ultra-fine materials. It is only necessary to control the opening and closing of the gate to complete the screening purpose with high quality. This kind of vibrating screen is suitable for industries such as traditional Chinese medicine powder and pollen.

2. Edged circular vibrating screen: It expands the feeding port on the existing conditions of the circular vibrating screen, and is also equipped with a special angle design to avoid the liquid bursting out of the filter type screening equipment, which is widely used in paint and water filtration. , pulp filtration and other industries.

3. Circular vibrating screen with hopper: The feeding port is equipped with a feeding hopper, which is convenient for feeding.

4. Mobile circular vibrating screen: the bottom is equipped with a universal wheel for easy movement, and it can be freely moved according to the needs of the site, which is more flexible.

| Model | A | B | C | D | E | F | H | I | 1 deck height (mm) |

2 deck height (mm) |

3 deck height (mm) |

Vibarion motor (kw) |

Common motor (kw) |

| DH-600 | 530 | 430 | 246 | 600 | 100 | 70 | 391 | 415 | 785 | 910 | 1040 | 0.25 | 0.75 |

| DH-800 | 680 | 580 | 246 | 800 | 125 | 80 | 514 | 430 | 855 | 1005 | 1155 | 0.55 | 1.1 |

| DH-1000 | 800 | 700 | 246 | 1000 | 150 | 95 | 615 | 430 | 865 | 1015 | 1065 | 1.1 | 1.5 |

| DH-1200 | 975 | 855 | 400 | 1200 | 180 | 100 | 717 | 550 | 1020 | 1170 | 1320 | 1.1 | 1.5 |

| DH-1500 | 1190 | 1050 | 400 | 1500 | 180 | 116 | 866 | 545 | 1090 | 1270 | 1440 | 1.5 | 2.2 |

| DH-1800 | 1580 | 1440 | 400 | 1800 | 200 | 150 | 1070 | 675 | 1230 | 1400 | 1570 | 3 | 3 |

| DH-2000 | 1800 | 1640 | 400 | 2000 | 200 | 190 | 1210 | 685 | 1280 | 1445 | 1615 | 1.5 | 3 |

Feed inlet: The design of the buffer plate makes the material flow into the screen surface evenly, and the material is inspected through the observation port.

Screen: The commonly used material is 304 stainless steel woven mesh, the mesh number can reach 500 mesh.

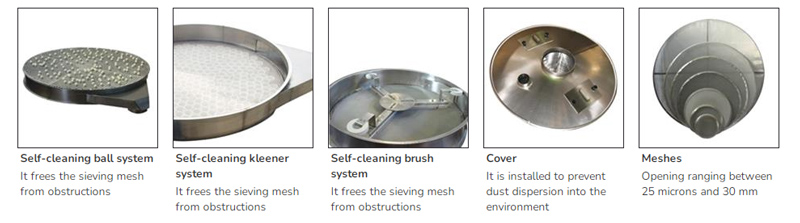

Cleaning device: A bouncing ball made of rubber/silicone material is commonly used, with an initial rebound capacity of 70%, which can prevent the screen from clogging. Ultrasonic and rotary brush cleaning devices can also be selected according to the nature of the material.

Vibration motor: vertical vibration motor, the power of the motor can be freely selected from 0.18KW to 4.0KW (the larger the diameter of the equipment, the greater the power of the motor used). For some special industries, explosion-proof vibration motors can be equipped.

Discharge port: The size of the discharge port can be designed according to the needs, and the discharge speed through the valve can be adjusted according to the needs.

Shock absorbing spring: steel spring is commonly used to buffer the vibration of the machine and reduce noise. The outside of the spring is sprayed, and the warranty is one year.

| MAYERIALS | MESH OPENING | CAPACITY | |||

| DH-600 | DH-0800 | DH-1200 | DH-1500 | ||

| Milk powder | 400 mm | 350 | 800 kg/h | 1.800 kg/h | 2.800 kg/h |

| Orange juice | 1000 mm | 1.6 | 3.500 l/h | 8.000 l/h | 12.000 l/h |

| Sweet pepper | 1000 mm | 180 | 350 kg/h | 1.000 kg/h | 1.300 kg/h |

| Flour | 300 mm | 300 | 600 kg/h | 1.350 kg/h | 2.100 kg/h |

| Ammonium sulfate | 350 mm | 400 | 900 kg/h | 2.000 kg/h | 3.100 kg/h |

| Toner | 100 mm | 90 | 170 kg/h | 400 kg/h | 600 kg/h |

| Glass powder | 100 mm | 270 | 500 kg/h | 1.300 kg/h | 2.000 kg/h |

| Purine | 125 mm | 2 | 4.000 l/h | 10.000 l/h | 15.000 l/h |

| Acrylic paint | 80 mm | 500 | 1.200 l/hour | 2.700 l/h | 4.200 l/hour |

DHHAN circular vibrating screen manufacturer is a direct sales rotary vibrating screen manufacturer. Our prices are lower factory prices to reduce user investment costs, and our product models are complete, and we can also customize design and production for each user. Since its establishment 12 years ago, we will help you solve practical problems in time, whether it is selection consultation or difficult handling. The company mainly provides parts warehouse sales for overseas markets and local customers, and provides materials and parts warehouse management services, parts supply planning management services, and machine maintenance and packaging services. It also provides original parts supply and distribution.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.