Specifically designed to handle all types of oils and oil-based products

![]()

![]()

Price::$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Diameter: 200mm-600mm

Length: 10-20 meters

Output: 9-134 tons/hour

Angle: horizontal or tilted below 20 degrees

Application: Efficient and reliable oil transportation ensures a stable supply of this key ingredient to downstream equipment (such as storage tanks, reactors, and distillation towers), and can be used in conjunction with other transportation equipment to complete joint transportation, separate transportation, mixing, blending, and dehydration , fine material and stacking, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Oil screw conveyor is a type of mechanical device used for the transportation of oil or oily substances. It consists of a rotating screw inside a cylindrical casing that helps move the oil from one point to another.Oil screw conveyors are commonly used in various industries, including food processing, agriculture, and manufacturing. They offer efficient and reliable oil handling, allowing for smooth and controlled movement of oil or oily substances within a production or processing system.

When it comes to oil screw conveyors, they are typically constructed using materials that are compatible with oils to prevent contamination and ensure the safe handling of the oil-based products. These conveyors are designed to efficiently transport oils without leakage or spillage, maintaining the integrity of the product being transported.

Oil screw conveyors are efficient and reliable for oil delivery, ensuring stable supply to downstream processes (e.g. storage tanks, reactors, distillation columns).

Oilfield production: Oil screw conveyors are often used to transport crude oil, natural gas, water and other materials. These materials need to be transported from the production well to processing equipment or storage facilities.

Refinery: Oil screw conveyors are widely used to transport oil products, such as crude oil, gasoline, diesel, kerosene, etc.

Oil storage: Oil screw conveyors are used to transport oil products from storage tanks to loading equipment or other processing equipment to ensure efficient transportation and storage of oil products.

Pipeline oil transportation: Through screw conveyors, oil products can be transported from one location to another, ensuring the smooth operation of the entire oil transportation system.

Chemical industry: Oil screw conveyors are used to transport viscous chemical products, such as lubricating oil, grease, etc., to ensure smooth transportation of products and efficient operation of the production process.

Solid waste transportation: used to transport solid waste such as drilling mud and cuttings from the drilling site to the disposal facility.

Efficient delivery

Screw conveyors are highly efficient at conveying oils and other viscous liquids, even at high viscosities. The helical design of the conveyor helps move the oil through the conveyor with minimal resistance, ensuring a steady flow of material.

Minimum overflow

The screw conveyor is designed with a dust seal to help prevent oil or other liquids from spilling during transport. This reduces the risk of accidents or environmental pollution.

Low maintenance

Screw conveyors are relatively low maintenance compared to other types of conveyors. They have fewer moving parts and require minimal lubrication, reducing maintenance costs and downtime.

Versatility

Screw conveyors can be designed to handle a wide range of oils and other viscous liquids, including crude oil, refined petroleum products and waste. They can also be designed to fit different factory layouts and transport materials over short or long distances.

Hygienic design

The screw conveyor can be designed with food-grade stainless steel, which meets the hygienic and safety requirements of the food processing industry. This makes them suitable for food applications such as the transportation of edible oils.

Customizable

Screw conveyor designs and configurations can be tailored to the specific requirements of the application, ensuring a seamless and efficient material handling process for oils and other viscous liquids.

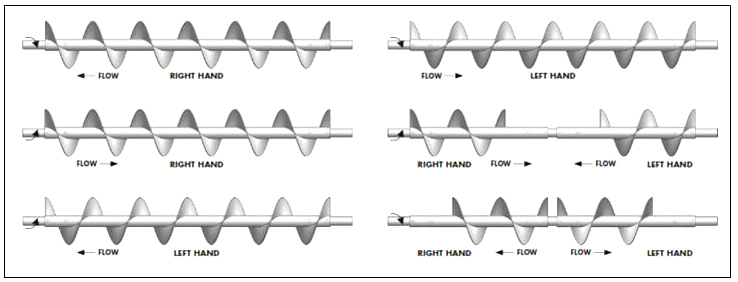

Oil screw conveyors are composed of screw blades, shafts, sleeves, bearing seats, etc. The screw blades are arranged in a screw shape along the rotation direction of the screw axis to form a conveying channel. When the screw conveyor is started, the screw blades rotate along the shaft to push or lift the material along the conveying channel. Due to the screw structure of the screw blades, the material will be affected by thrust and resistance during transportation, thereby completing the transportation process.

| Specification | Main technical performance | Drive device | Drive device | Weight(kg) | |||

| Diameter | Length(m) | Yield( t/h) | Rotating speed(min) | Reducer | Electric motor | ||

| Model | Speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

Screw conveyors for oil transportation can have a variety of customized options according to the specific needs of customers. Here are some common customization options:

1. Material selection: The screw and conveying pipe of the Oil screw conveyor can be made of materials suitable for oil transportation, such as stainless steel, carbon steel or coated materials. Material selection will be determined based on factors such as the type of oil being transported, temperature and chemical properties.

2. Size and capacity: The size and capacity of Oil screw conveyor can be customized according to customer requirements. This includes the diameter, length and speed of the screw, as well as the overall size and capacity of the conveyor.

3. Conveying speed and control: According to the properties of the oil and the needs of the production line, the conveying speed of the screw conveyor can be adjusted and controlled. Customers can select the appropriate drive system, frequency converter or speed regulator to achieve the required conveying speed and control.

4. Conveying direction and angle: Oil screw conveyor can carry out horizontal, inclined or vertical conveying, depending on the customer's layout requirements. The conveying angle can be adjusted and customized according to the actual situation.

5. Conveying system accessories: According to customer needs, different accessories can be added to enhance the functionality and adaptability of the screw conveyor. For example, oil seals, explosion-proof devices, cleaning devices, adjustable diversion devices, etc. can be installed.

Here are three customer cases of oil screw conveyor:

1. Oil drilling company: An oil drilling company in the Middle East was looking for a reliable and efficient solution to transport drilling mud and cuttings from the drilling site to the disposal facilities. They chose an oil screw conveyor due to its ability to handle the high viscosity and abrasive nature of the materials. The screw conveyor was designed with a dust-tight cover and seals to prevent spills and to maintain a safe working environment.

2. Petroleum refinery: A petroleum refinery in the United States was looking for a solution to transport refined petroleum products from the refinery to the distribution facilities. They chose an oil screw conveyor due to its ability to handle the high viscosity of the products and to ensure a steady flow of material. The screw conveyor was designed with a variable speed drive to control the rate of flow and to prevent overloading or underfeeding the downstream equipment.

3. Edible oil processing company: An edible oil processing company in Asia was looking for a hygienic and efficient solution to transport edible oils from the storage tanks to the production lines. They chose an oil screw conveyor made of food-grade stainless steel to ensure the hygiene and safety of the product. The screw conveyor was designed with a dust-tight cover and seals to prevent contamination and to maintain the quality of the product.

There are several factors to consider when selecting an oil screw conveyor for an oil industry application. Here are some key things to note:

1. Material characteristics: The characteristics of the oil or other viscous liquids to be transported should be considered, including viscosity, density, abrasiveness, etc. This will affect the screw conveyor design, including pitch, diameter and speed.

2. Capacity and throughput: The required capacity and throughput of the screw conveyor should be determined to ensure it can handle the production requirements. The length, diameter and speed of the conveyor should be selected accordingly.

3. Sanitation and safety: If oil or other liquids are used in food or pharmaceutical applications, the screw conveyor should be made of food-grade stainless steel and designed with dust covers and seals to ensure hygiene and safety.

4. Space limitation: The available space of the screw conveyor should be considered, including the length, height and inclination of the conveyor.

5. Maintenance requirements: The maintenance requirements of the screw conveyor should be considered, including the frequency of lubrication, cleaning and inspection. Screw conveyors with fewer moving parts and easy maintenance help reduce downtime and maintenance costs.

6. Compatibility with downstream equipment: the screw conveyor should be compatible with downstream equipment, including tanks, reactors, distillation towers, etc. Conveyors should be designed to convey oil or other liquids at the required flow rate and pressure.

Xinxiang Dahan is a manufacturer of oil screw conveyors. Dahan designs and manufactures high-quality oil screw conveyors for conveying oil from one location to another. These conveyors use advanced technology and reliable construction to ensure stable operation and long-lasting use. Dahan's oil screw conveyors are efficient, energy-saving and adjustable, suitable for oil conveying needs of different scales. The products produced by Dahan are widely used in industries such as oil processing, food processing, and agricultural fields, and are well received and trusted by customers.

We are a manufacturer specializing in the production of oil screw conveyors, dedicated to providing high-quality, high-efficiency conveying equipment solutions for the oil industry. We have rich experience and technical strength, and have a good reputation in the field of oil screw conveyors. We provide customized design solutions and customized production according to the specific requirements of customers and site conditions to ensure the perfect match between the equipment and the production line. The price is $500.00 - $20,000.00/Set. If you are looking for a reliable oil screw conveyor manufacturer, please contact us!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.