It is a spiral metal sheet used to transport materials along the direction of the screw axis.

![]()

![]()

Price:$50.00-$200.00/Set

Consult now and enjoy a 10% discount

Thickness: 3.5mm

OD:60-3000mm

ID:30-2500mm

Pitch: 60-3000mm

Material: Carbon Steel、Stainless Steel、Wear Resistance Steel

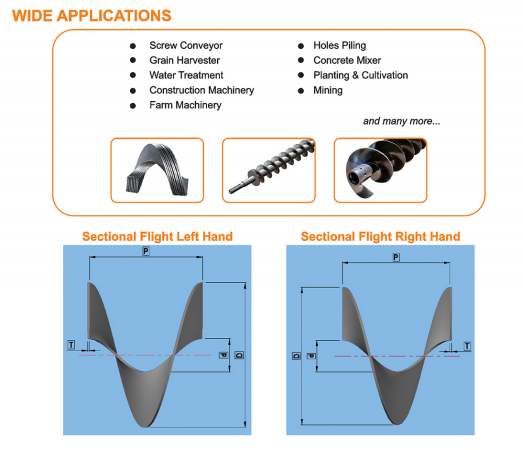

Application: It is widely used in various industrial fields to convey various materials such as powder, granules, and blocks.

Commitment:

Screw conveyor blades are the helical components that form the spiral shape within a screw conveyor.They are responsible for the efficient transportation of bulk materials, including powders, granules, and small objects, along the length of the conveyor.

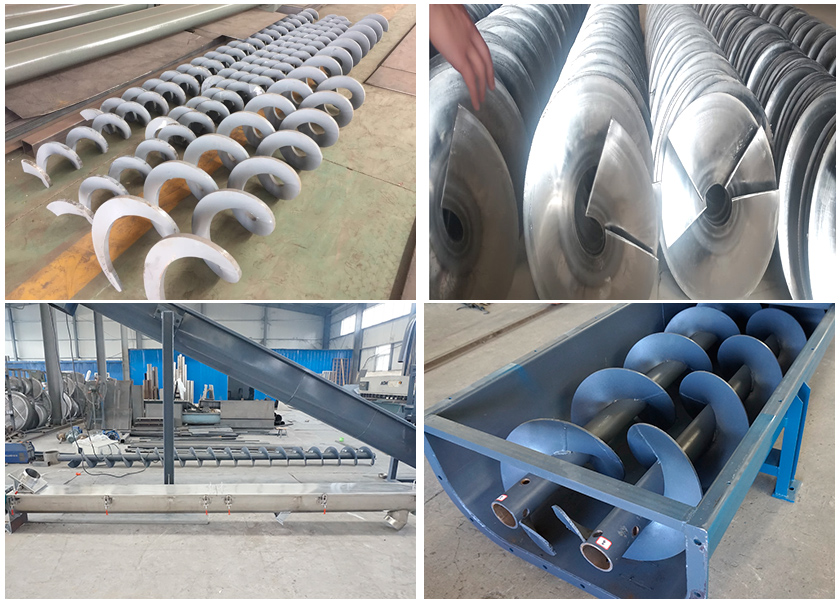

We can offer you a wide range of designs such as simple blades, serrated blades, conical blades, blades with irregular pitch, with and without shaft, etc.

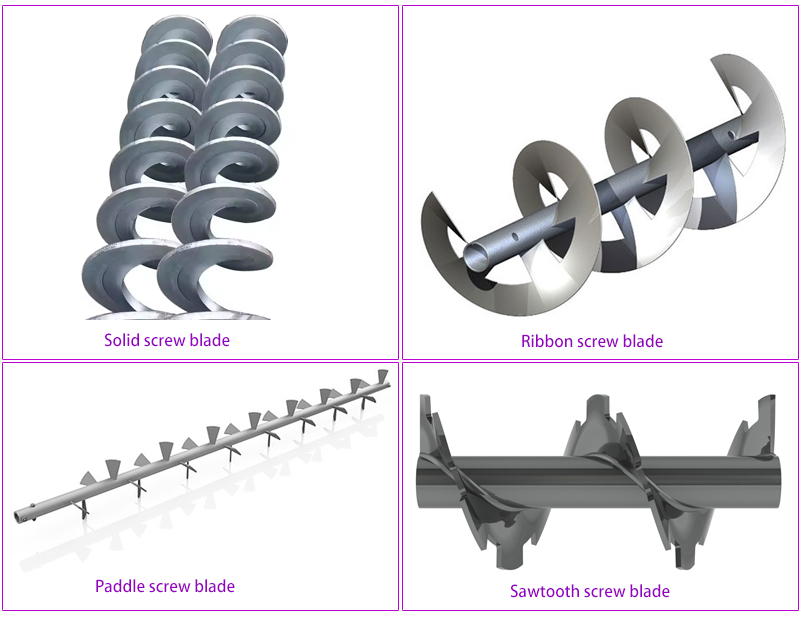

There are several types of screw conveyor blades designed to suit different material handling needs and applications. Here are some common types of screw conveyor blades:

1. Different forms

1. Solid screw blade: The full-leaf blade is directly welded or riveted on the shaft, suitable for dry powder or small granular materials.

2. Ribbon screw blade: It is fixed to the shaft with a radial rod, suitable for block materials with a certain viscosity.

3. Paddle screw ade: The paddle design can blend and stir the material.

4. Sawtooth screw blade: It has a serrated groove, which plays a mixing role such as cutting, loosening, and stirring.

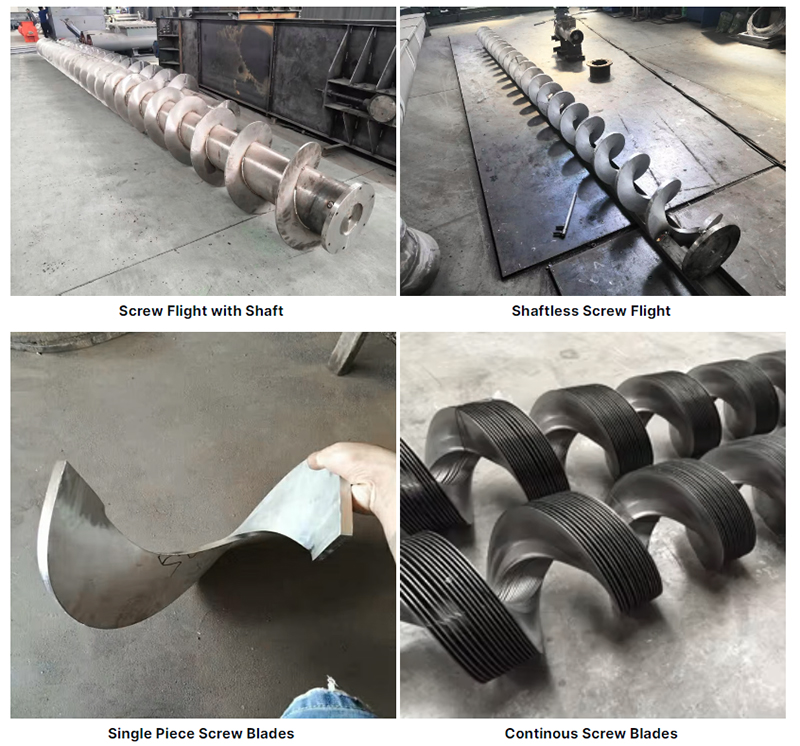

2. Different structures

Shafted screw blades: The blades are fixed on the central shaft. The central shaft and the blades are an integral component, which is suitable for processing relatively hard, granular materials.

Shaftless screw blades: There is no central shaft, and the blades themselves have load-bearing and transmission functions. Suitable for processing soft, easily deformed or highly viscous materials.

3. Different materials

Carbon steel material: It has good strength and wear resistance, is suitable for general industrial application environments, has low cost, and is suitable for processing general granular materials.

Stainless steel material: It has excellent corrosion resistance and wear resistance, and is suitable for humid or highly corrosive environments. Compared with carbon steel, the cost of stainless steel is higher.

Manganese steel material: It has extremely high wear resistance and impact resistance, and is suitable for processing materials with severe wear or high-intensity working conditions. It is usually more expensive than carbon steel and stainless steel.

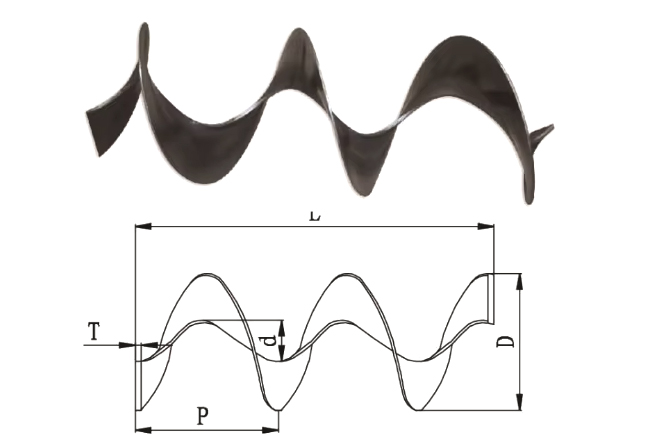

| Model | LY125 | LY160 | LY200 | LY250 | LY320 | LY400 | LY500 |

| OD D (mm) |

φ125 | φ160 | φ200 | φ250 | φ320 | φ400 | φ500 |

| ID d (mm) |

φ30 | φ42 | φ48 | φ60 | φ76 | φ108 | φ133 |

| Pitch P (mm) |

100-125 | 120-160 | 160-200 | 200-250 | 250-320 | 320-400 | 400 |

| Thickness T (mm) |

3.5 | 3.5 | 3.5 | 3.5-5 | 3.5-5 | 3.5-5 | 3.5-5 |

| Pitch P (mm ) |

Min ID (mm) |

Max OD D (mm) |

Ratio of OD and ID | Max OD (mm) |

Thickness T (mm) |

| 60-100 | 20 | 480 | 0.25 | Min OD =Pitch customized X ratio | 3-16 |

| 100-150 | 30 | 480 | 0.25 | 3-18 | |

| 150-200 | 50 | 520 | 0.33 | 3-20 | |

| 200-250 | 60 | 630 | 0.30 | 3-25 | |

| 250-300 | 65 | 670 | 0.25 | 3-25 | |

| 300-350 | 90 | 900 | 0.30 | 3-30 | |

| 350-400 | 90 | 520 | 0.25 | 3-30 | |

| 400-450 | 95 | 950 | 0.25 | 3-30 | |

| 450-500 | 135 | 1150 | 0.33 | 3-35 | |

| 500-550 | 150 | 1200 | 0.30 | 3-40 |

When choosing screw conveyor blades, the following key factors need to be considered:

Material characteristics: Select suitable blades according to the density, particle size, abrasiveness and other characteristics of the conveyed material to ensure effective conveying and prevent blockage.

Working environment: Consider factors such as temperature, humidity and corrosiveness of the working environment, and select corrosion-resistant and wear-resistant blades to adapt to different environmental conditions.

Required processing capacity: Determine the design and size of the blades according to the amount of material to be processed per unit time to ensure that the required processing capacity requirements are met.

Screw conveyor configuration: Consider parameters such as the length, diameter and pitch of the screw conveyor, and select blades that are suitable for its configuration to ensure smooth material transportation and efficient operation.

Special requirements: For materials that are prone to agglomeration or adhesion, select blades with special designs, such as belt blades or mixing blades.

Maintenance and cleanability: Select blades that are easy to clean and maintain to avoid material accumulation and ensure hygiene requirements, especially suitable for the food or pharmaceutical industry.

Screw conveyor blades have the following characteristics:

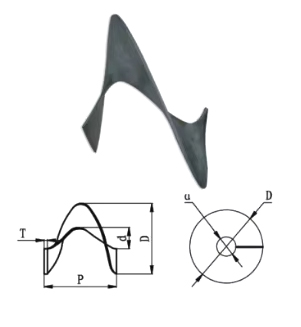

Spiral shape: The blades are spiral-shaped and rotate around the central axis to form a continuous spiral channel. This design effectively propels material along the length of the conveyor.

Various Shapes and Types: Screw conveyor blades can come in a variety of shapes and types depending on different application requirements. For example, standard pitch blades, short pitch blades, cutting blades, ribbon blades and mixing blades, etc. Different types of blades are suitable for different material characteristics and conveying requirements.

Material selection: Screw conveyor blades are usually made of materials with good wear resistance to ensure their durability and service life. Common blade materials include carbon steel, stainless steel and wear-resistant alloys. The choice of material depends on the characteristics of the conveyed material, such as abrasion, temperature and chemical properties.

Customizability: Screw conveyor blades can be customized to meet specific application needs. For example, the pitch, diameter and blade shape of the spiral can be adjusted to adapt to the conveying requirements of different materials.

Wear resistance and easy cleaning: Since the screw conveyor blades are in direct contact with the material during the material transportation process, they need to have good wear resistance. In addition, the easy-to-clean design can reduce material residue and reduce the difficulty of maintenance and cleaning.

Xinxiang Dahan screw conveyor blade manufacturer has many years of experience and professional knowledge, and has accumulated rich experience in the design, manufacturing and application of screw conveyor blades. They understand the needs of different industries and can provide customized blade solutions. Ye Dahan Company currently supplies spiral blades with an outer diameter of up to 1250mm and a thickness of ≤60mm. Other specifications can be customized according to user requirements.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.