Screw conveyors play an important role in wastewater treatment by transporting and handling solids and sludge from one stage of the treatment process to another.

Sludge Dewatering: Screw conveyors are commonly used in sludge dewatering applications to transport and handle the solids that are separated from the wastewater. The screw conveyor can help to remove excess water from the sludge, reducing its volume and making it easier to handle and dispose of.

Grit Removal: Screw conveyors can be used to remove grit and other heavy materials from the wastewater during the primary treatment stage. The grit is transported up the inclined screw and deposited into a container for further processing or disposal.

Biosolids Handling: Screw conveyors can be used to transport and handle biosolids, which are the organic materials that are generated during the wastewater treatment process. The screw conveyor can help to mix and blend the biosolids, making them easier to handle and transport.

Chemical Feeding: Screw conveyors can be used to transport and handle the chemicals that are used in the wastewater treatment process, such as coagulants, flocculants, and disinfectants. The screw conveyor can help to ensure accurate dosing of the chemicals and can be designed to handle corrosive or abrasive chemicals.

Solids Handling: Screw conveyors can be used to transport and handle a wide range of solids that are generated during the wastewater treatment process, such as screenings, grit, and biosolids. The screw conveyor can help to ensure efficient and reliable handling of the solids, reducing the risk of clogs and other issues.

Shaftless screw conveyors are commonly used in the wastewater treatment industry due to their many advantages over traditional shafted screw conveyors. Here are some application advantages of using shaftless screw conveyors in wastewater treatment:

Reduced maintenance: Shaftless screw conveyors have fewer components than shafted screw conveyors, which means fewer parts to maintain and replace. With no central shaft, the risk of clogging or clogging is eliminated, reducing maintenance and downtime.

Ability to Handle Difficult Materials: Shaftless screw conveyors can handle difficult materials such as sticky or fibrous materials that can cause shafted screw conveyors to clog or seize. The absence of a central shaft also enables greater capacity and eliminates the risk of galling or winding.

Increased efficiency: Shaftless screw conveyors are more efficient than shafted screw conveyors because they have larger troughs and can handle higher capacities. They also consume less power, which saves energy.

Reduced wear: Shaftless screw conveyors have no central shaft, meaning there is no direct contact between the screw and chute, reducing wear on components. This extends equipment life and reduces maintenance costs.

Environmental benefits: Shaftless screw conveyors are fully enclosed, which means they help reduce dust and noise emissions. They can also be designed with an odor control system to minimize unpleasant odours.

The following are examples of screw conveyors used in the wastewater treatment industry:

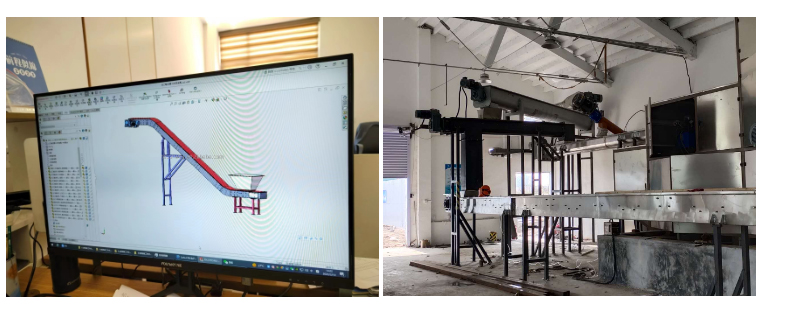

Customer Case: Sewage Treatment Plant

Wastewater treatment plants use multiple screw conveyors in various applications throughout the treatment process. An example is the use of shaftless screw conveyors in biosolids handling. The biosolids are conveyed from the primary clarifier to the anaerobic digester using a shaftless screw conveyor. The shaftless design helps prevent clogging and clogging, which can be common problems with the viscous and fibrous nature of biosolids.

Another example is the use of inclined screw conveyors to transport gravel and other heavy materials from the chamber to the dewatering process. The angle of inclination helps ensure efficient material transfer, and the screw can be designed with abrasive materials to counter the abrasive nature of the grit.

In both applications, screw conveyors are designed to handle the high volumes required in large wastewater treatment plants. They are also designed with environmental factors in mind, such as dust and odor control systems.

Overall, screw conveyors are an important component of wastewater treatment systems, helping to transport and handle solids and sludge throughout the treatment process. They can be customized to meet specific requirements and can be designed to handle even the most challenging materials with minimal wear and tear.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.