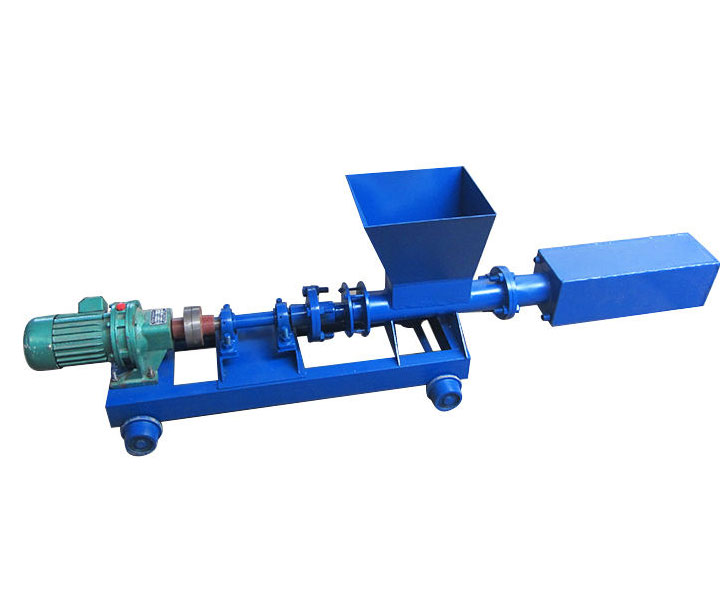

It is used to evenly feed non-sticky powdery, granular and small granular materials from storage equipment such as silos to receiving equipment.

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Diameter: 100-1250mm

Angle of inclination: 0-90 degree

Contact part material: Mild steel,SUS304 or SUS316L

Hopper Size: 100L, 230L Feeding rate: 244m³/h

Loading capacity: 250kg

Conveying height: ≤8 meters

Power Supply: 380V/220V 50-60Hz Power: 1.5-5.5KW

Application: For continuous or batch operation, can feed granular, powder, viscous or adhesive type materials, and is the choice of users who require particularly efficient discharge/feed from silos or hoppers

Commitment:

Screw feeder conveyor is a mechanical conveying system that uses a rotating screw to move material from one point to another and is the choice of users who require particularly efficient discharge/feed from silos or hoppers. Screw feeder conveyor is designed to measure and control the flow of materials entering the process, such as mixing or mixing operations. It can be customized according to user requirements with different diameters, different lengths, and different inclination angles. It can be equipped with a speed-regulating motor to continuously adjust the speed to achieve quantitative feeding.

There are several types of screw feeder conveyor available, each designed for specific applications. Here are some of the most common types:

1. Horizontal Screw Feeder Conveyor: This type of screw conveyor is designed to transport bulk materials horizontally from one point to another. It is commonly used for material handling applications in industries such as food processing, chemical processing, and agriculture.

2. Vertical Screw Feeder Conveyor: This type of screw conveyor is designed to transport bulk materials vertically, often used to elevate materials from one level to another. It is commonly used in industries such as construction, mining, and agriculture.

3. Inclined Screw Feeder Conveyor: This type of screw conveyor is designed to transport bulk materials at an incline, often used to move materials between floors or up an incline. It is commonly used in industries such as food processing, chemical processing, and pharmaceuticals.

4.Twin screw feeder conveyor: Consists of two parallel, counter-rotating screws. This design allows for higher material throughput and greater mixing capacity than single screw conveyors. Twin screw feed conveyors are commonly used in industries such as food processing, chemical processing and pharmaceuticals.

5.Volumetric screw feeder conveyor: This type of screw feeder is designed to deliver a fixed volume of material per unit of time. It is commonly used in applications where precise dosing of material is required, such as in the food and pharmaceutical industries.

6. Shaftless screw feeder conveyor: This type of screw conveyor has no central shaft, which allows it to handle material that would otherwise wrap around a conventional screw. It is commonly used for handling materials such as sludge, gravel, and other abrasive or sticky materials.

Screw feeder conveyors are used to transport and handle bulk materials in a wide range of industrial applications. Some common uses for screw-fed conveyors include:

1. Metering and batching: It is commonly used in the metering and batching of materials in many industries such as food processing, chemical processing and pharmaceuticals. They can be designed to provide precise flow or material volume, making them suitable for applications where accurate metering is critical.

2. Mixing and stirring: It can be used for mixing and stirring powdery, granular, pasty and other materials. They can be designed with different types of screws, such as helical, ribbon or paddle, to achieve the desired mixing characteristics.

3. Conveying and conveying: It is often used for conveying and conveying materials between different stages of the production process. They can be used to move material horizontally, vertically or obliquely, making them suitable for a wide range of applications.

4. Filling and packaging: It can be used to fill and package materials such as powder and granules into bags, containers or other packaging forms. They can be engineered to deliver precise quantities of material, making them suitable for applications where precise filling is critical.

5. Garbage disposal: It can be used for the disposal and transportation of garbage materials, such as sludge, gravel and other sundries. They can be designed to handle abrasive and corrosive materials, making them suitable for use in wastewater treatment, mining and other industries.

Screw feeder conveyor is mainly composed of feed port, spiral blade, cylinder, hopper, drive device, discharge port and other parts. During operation, after the material is conveyed to the housing of the screw feeder through the feed port, the material is subjected to the centrifugal force and the frictional force of the pipe wall in the internal spiral groove, and rotates with the spiral blades, and moves along the spiral under the action of gravity. The trough slides downwards, so that the material is continuously pushed forward and conveyed, and evenly discharged from the discharge port.

Versatility

A wide range of materials can be handled including powders, granules, pellets and other bulk materials. They can also be designed to handle materials with different flow characteristics, such as viscous, abrasive or brittle materials.

High efficiency

Conveys material with high efficiency and a continuous flow of material that can be controlled and adjusted to meet specific application requirements. They can also be designed to run at different speeds and feed rates to optimize efficiency.

Consistent dosing

Can provide a consistent and accurate material feed rate to the process, which is important to maintain the quality and consistency of the final product.

Reliability

Is a reliable material handling solution, simple in design, easy to maintain and operate, durable and resistant to wear, thus ensuring long life and reducing downtime.

Cleanliness

Can meet stringent hygienic standards, making it suitable for industries such as food processing and pharmaceuticals. They can be made of materials that are easy to clean and sanitize, and are hermetically sealed and closed to prevent contamination.

Custom made

Can be customized to meet specific application requirements, with different sizes, shapes and characteristics. They can be designed to fit into existing lines and processes and can be integrated with other equipment such as mixers, extruders and packaging machines.

screw feeder conveyor for grain

small screw feeder conveyor

Screw feeders and screw conveyors are two different types of mechanical conveying systems that serve different purposes. Screw feeders are designed for precise metering of materials into a process, while screw conveyors are designed for moving materials from one point to another over longer distances or elevated heights. Here are some other key differences between screw feeders and screw conveyors:

| Comparison item | Screw Feeder | Screw Conveyor |

|

|

|

| Speed | 5-20 RPM | 100-600RPM |

| Capacity | Used to process relatively small volumes of material, typically a few grams to a few pounds per minute. | Larger volumes can be handled, ranging from a few hundred pounds to several tons per hour. |

| Design | There are shorter screw lengths and larger diameters for better control of material flow. | Available in longer screw lengths and smaller diameters to maximize material throughput. |

| Application | Typically used in applications where precise metering of materials is critical, such as in the food and pharmaceutical industries. | For applications where material needs to be transported over longer distances or heights, such as in the mining and construction industries. |

| Material handling | It is designed for processing materials that are relatively easy to handle, such as powder, granular, flake, etc. | Can handle a wider range of materials, including abrasive and corrosive materials. |

Screw feeder conveyors can be customized to meet specific requirements and to suit the material being conveyed. Here are some examples of custom types of screw feed conveyors:

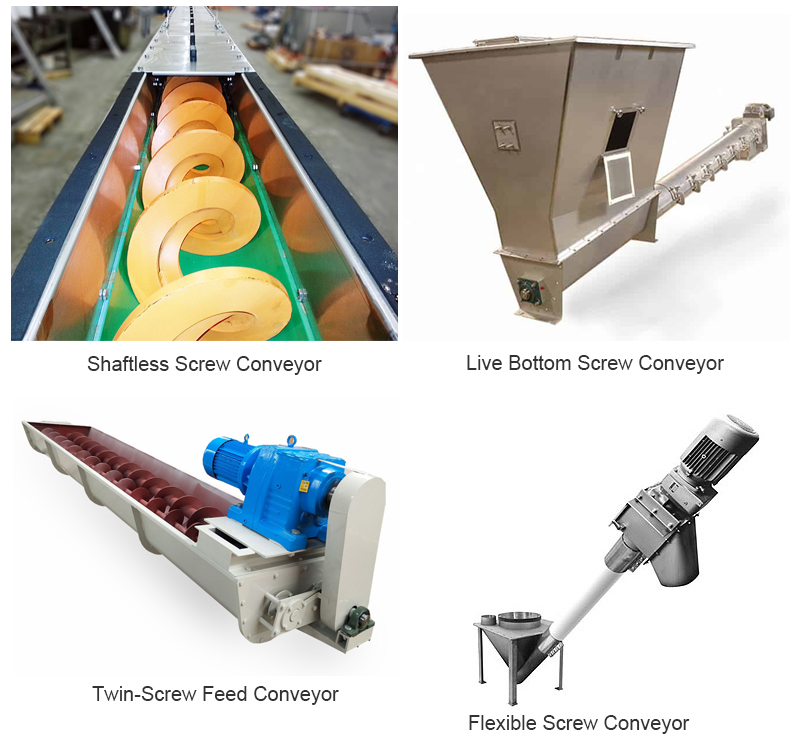

Shaftless Screw Conveyor: This type of screw conveyor has no central shaft, making it easier to clean and maintain. It is often used to move sticky or viscous materials that can clog conventional screw conveyors.

Live Bottom Screw Conveyor: This type of screw conveyor is used to convey difficult materials such as wet or sticky materials. It features a series of independently moving blades to prevent materials from sticking together or clumping.

Twin-Screw Feed Conveyor: This type of screw conveyor has two screws that rotate in opposite directions for better control of the flow of material. It is typically used in applications requiring consistent and precise flow.

Flexible Screw Conveyor: This type of screw conveyor has a flexible tube that can be bent and twisted to fit the available space. It is ideal for use in tight spaces and complex production layouts.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

The screw feeder is mainly composed of driving device, head section, middle section, tail section, head and tail bearings, feeding and discharging device and other parts.

Drive device: composed of motor and reducer

Suspension bearing: sliding bearing is used, equipped with dust-proof sealing device, and the suspension shaft and screw shaft are connected by sliders.

Spiral: It is mainly composed of a shaft and a helical blade welded on the shaft.

Screw feeder conveyor has a variety of options, including:

1. Screw selection: Screws can be customized according to specific application requirements. This includes options such as pitch, diameter and thread configuration, as well as different screw types such as helical, ribbon or paddle.

2. Material selection: Can be made of different materials according to application requirements. Common materials include stainless steel, carbon steel, and plastic.

3. Controls: Different types of controls can be equipped, including manual, semi-automatic and automatic controls. Automatic controls can include sensors, timers, and other devices that help regulate the flow of material.

4. Hoppers: Can be designed to accommodate different types of hoppers, depending on the type of material being handled. This includes options such as open hoppers, closed hoppers and surge tanks.

5. Feed Rate: Can be designed to provide precise feed rate, depending on application requirements. This can be achieved through the use of speed controls, sensors and other devices.

6. Size and capacity: Can be designed to accommodate different sizes and capacities, depending on the volume of material being handled. This includes options such as single-screw, twin-screw and multi-screw screw feeder conveyors.

Silo, hopper emptying screw conveyor

Screw feeders placed below silos, hoppers, or other containment systems are used to control the discharge of bulk solids (in powder or granular form) from these units and from feeding equipment such as conveyors, mixers, etc.

Dust removal system, bag filter

Dust collectors, filters, and jet pulse filters are used to collect dust generated in the production line. The screw conveyor installed under the dust removal system is used to unload the collected dust.

Mixing, batching, batching system

Screw feeder conveyors can be used to control the discharge of bulk solids. Volumetric measurement of powdered and granular bulk materials is possible by controlling the shaft speed of the screw feeder. Gravity feeding of mixers or containers is accomplished by measuring the weight of the product being processed.

Bulk solid handling equipment uses screw conveyor for feeding/discharging

In some industrial processes, bulk solids processing equipment can be fed or unloaded with the help of screw conveyors. Feeding, batching, mixing, crushing processes are some examples where screw conveyors are used.

Dahan screw feeder conveyor manufacturer Dahan double-axis screw conveyor has been established for more than 15 years. The screw feeder conveyor has a complete range of models and provides relevant accessories. The quality of the project is not guaranteed, the risk is high, there are many disputes, and the cost is high. The integrated and rapid construction is completed by the installation team in one stop. The team is unified, rework is reduced, and the quality of the project is guaranteed. The product is delivered on the same day or the next day, shortening Shorten the construction period and reduce the waiting time of customers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.