Alumina powder is a functional bulk material commonly used in the industry, and is often used in the production of dental cement, functional ceramics, fillers for paints, mordants, adsorbents, chromatography and other scenarios.

When the alumina powder is applied, it needs to be dispersed in a single particle, otherwise the purpose of being used as a dispersant, filler, etc. cannot be fully achieved. If the alumina powder is agglomerated, its performance will also be affected, and the ideal use effect cannot be achieved.

The fineness of alumina powder for chemical industry can be as high as 200 mesh and 325 mesh, and it is required that single particles be dispersed without agglomeration. Whether the alumina powder produced in industry is sold or the alumina powder needs to be used, in order to achieve the desired commodity price or use effect, the alumina powder should be sieved, and the fine, high-mesh powder should be sieved. Ultrasonic vibrating sieve is commonly used.

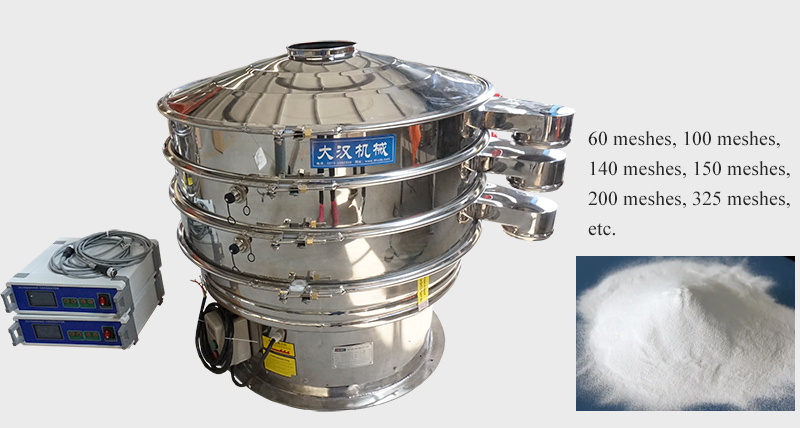

The mesh size of the ultrasonic vibrating sieve for alumina powder can reach 600 meshes, which can meet the sieving requirements of most alumina powders (60 meshes, 100 meshes, 140 meshes, 150 meshes, 200 meshes, 325 meshes, etc.), And it can design 1-5 layers of sieve mesh, which can process alumina powder of various specifications and meshes at the same time.

1. High-frequency and low-amplitude vibration can make alumina powder pass through the sieve quickly, and the sieveing output can reach 2-5 times that of ordinary vibrating sieve;

2. The 38KHZ high-frequency electric energy can break the false agglomeration formed by the alumina powder after grinding or due to long-term moisture, and the net passing rate is higher;

3. The ultrasonic system can keep the alumina powder suspended at a low altitude, which is equivalent to a net cleaning device and will not block the net;

4. The net is fast and the dust is small. Even if there is no cover for sieveing, there will be no excessive alumina powder dust or waste.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.