Double deck vibrating screen

Double deck vibrating screen Double deck horizontal vibrating screen

Double deck horizontal vibrating screen Stainless steel deck vibrating screen

Stainless steel deck vibrating screen Mobile double deck vibrating screen

Mobile double deck vibrating screen Mobile double deck vibrating screen

Mobile double deck vibrating screen

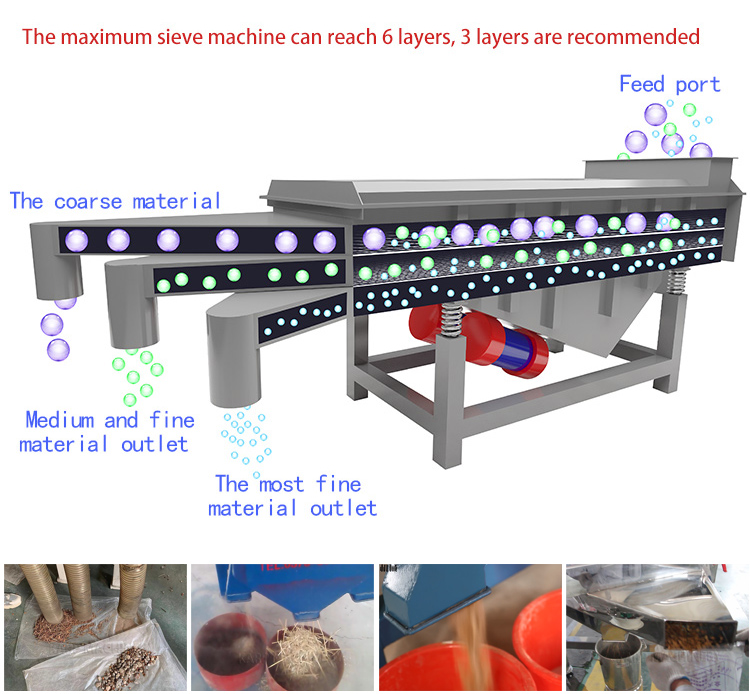

3 different gradings can be achieved in one operation

![]()

![]()

![]()

Price:$900.00-$4,800.00/Set

Consult now and enjoy a 10% discount

Layers: 2 layers Outlet: Outlet:

Uses: Simultaneous screening of materials into 3 different sizes

Feed particle size: 0.074-10mm

Number of meshes: within 400 meshes

Output: 0.12-20 tons/hour Processing capacity: 0.12-20t/h

Power: 2×(0.4-1.5)kw Voltage: 380V

Vibration acceleration: no more than 7g (g: acceleration of gravity)

Screen inclination: 0°-7°

Application: food, plastic, abrasive, chemical, pharmaceutical, building material, grain, carbon, fertilizer and other industries

Commitment:

Double deck vibrating screen, also known as double deck screen, double deck linear vibrating screen,consists of two decks or levels of screens stacked on top of each other, with each deck having different mesh sizes to allow for the separation of different particle sizes.The double deck vibrating screen operates by vibrating the screens in a linear motion, which helps to effectively separate and classify the materials being processed. This type of vibrating screen is commonly used in industries such as mining, aggregate, recycling, and construction to efficiently sort and classify materials based on size.

Double deck vibrating screen has the advantages of high screening accuracy, easy operation and convenient maintenance, and can effectively improve the screening efficiency and material quality in the production process. It is widely used in food, medicine, chemical industry, plastic particles, abrasives, quartz sand and other industries to remove oversized particles, impurities and other foreign matter in products.

1. Removal of impurities: Prevents agglomerates, oversized products or large particles that can cause problems in subsequent processing or quality control, while maintaining optimal performance feed rates.

2. Classification: While removing the coarse material from the fine material, it is used for the separation of different particle sizes of the same product, and one product can be separated into 3 kinds of finished products of different specifications, which are used for the homogenization of particles, etc.

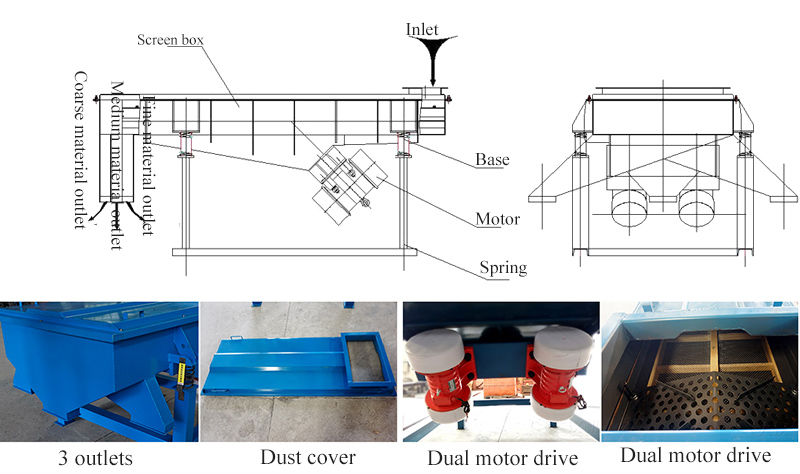

Vibration source produces vibration: Double deck vibrating screen is usually equipped with a vibration motor or vibrator as the vibration source. The vibration source will generate vibration force, which is transmitted to the screen and screen box.

Material feeding and layered screening: The material to be screened enters the screen box of the double-layer vibrating screen through the feeding port. Under the action of vibration, the materials are initially screened on the upper screen of the screen box. Larger particles will be blocked and cannot pass through the screen, while smaller particles will enter the lower layer through the screen.

Secondary screening: The materials screened by the upper screen will continue to pass through the lower screen for secondary screening.

Material separation and collection: According to the screening results, materials of different particle sizes will pass through the screen respectively. The finer materials will fall through the screen into the collecting port below, while the coarser materials will be blocked above the screen.

Double screen

There are 2 layers of screens and 3 discharge ports, which can classify a material into 3 different particle size specifications, and the classification accuracy can reach more than 96%.

High throughput

Double motor drive vibration, large processing capacity and low energy consumption, can process 20 tons of powder or granular materials per hour.

Prevent dust from spreading

The fully enclosed structure design prevents a large amount of dust and materials from splashing and falling during the screening process, improving the working environment.

Can be customized

Height/tilt angle/dust removal port and inlet and outlet ports can be designed as needed, and can be seamlessly connected to various production lines and production processes.

Reduce production costs

Double deck net is used, the upper net protects the lower net, and the lower net protects the finished material, which plays a role in improving the quality of the finished product of the screened material.

Adjustable

The spacing and inclination of the screen surface can be changed according to the particle size of the material, the probability of passing through the screen, and the productivity. The bracket is designed as a live opening, which is convenient for everyone to adjust the angle of the screen box.

Single deck vibrating screen and double deck vibrating screen are two common vibrating screening equipment, and they have some differences in structure, function and application.

| Features | Single Deck Vibrating Screen | Double Deck Vibrating Screen |

|

|

|

| Number of screening layers | 1 layer | 2 layers |

| Screening material (particle size) | 2 particle sizes (screened and underscreen) | 3 particle sizes (upper layer, middle layer and underlayer) |

| Processing capacity | Relatively high, large screen area, large screen volume | Relatively low, the screen area is distributed to each layer, and the screening volume is relatively small |

| Structural complexity | Simple structure, easy to maintain | The structure is relatively complex and the maintenance is slightly difficult |

| Application scenarios | Requires simple material classification, such as coarse and fine material classification, impurity removal, etc. | The material needs to be classified more finely, such as dividing the material into 3 different particle sizes |

| Cost | Low cost | Higher cost |

| Occupied area | Relatively large | Relatively small |

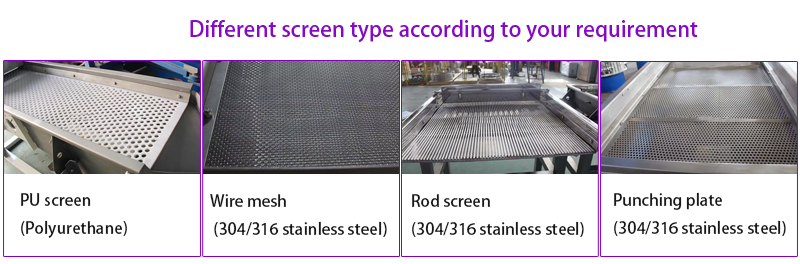

| Screen material | Screens of different materials can be selected according to material characteristics (such as stainless steel, nylon, polyurethane, etc.) | Different materials can be selected according to the screening requirements of different layers |

| Applicable materials | Granular and powdery materials | Granular and powdery materials, materials with higher screening accuracy requirements |

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Double deck vibrating screens consist of the following main components:

Screen box: used to accommodate the screen mesh and materials for screening.

Vibration source: such as vibration motor or vibrator, which generates vibration force and transmits it to the screen box.

Screen: including upper and lower layers of screen, used for screening materials.

Feed port: for materials to enter the screen box.

Discharge port: used to collect screened materials.

Support structure: supports the entire vibrating screen equipment.

Control system: used to adjust vibration amplitude, frequency and other parameters.

Screen: There are several types of screens such as low carbon steel, brass, bronze, and stainless steel wire.

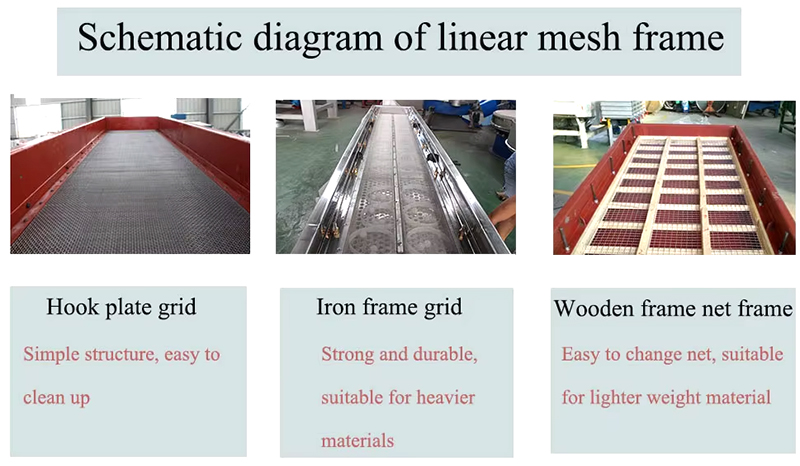

Sieve frame: There are two options of wooden sieve frame and metal sieve frame. The cost of wooden sieve frame is lower and the replacement is more convenient. It is suitable for the screening of powdery products. The metal sieve frame is durable and has two materials of carbon steel and stainless steel. Special products Optional stainless steel material, high temperature resistance, corrosion resistance, easy to clean.

Discharge port: usually in two ways, one is a round flange design, which is convenient to connect the discharge port of the previous process equipment and the feed port of the vibrating screen with a soft connection, and the other is a square port type. It is usually funnel-shaped, which is convenient for users to feed or use other equipment to feed. It adopts an open design and does not need a dust cover on the upper part of the machine. The conveyor directly transports the materials to the double deck vibrating screen.

Double deck vibrating screens are mainly used for screening dry powder, fine powder and granular materials in chemical, mining and mining, pharmaceutical, food, metallurgy, building materials, grain and other industries.

The following are some specific application:

Mining and Mining Industry: Used for screening and classifying coal, ore, limestone and other minerals to help improve the grade and extraction efficiency of the ore.

Building materials industry: used for screening sand, cement, concrete and other building materials to ensure that the raw materials meet production requirements.

Chemical industry: suitable for screening chemical raw materials and granular chemical products to ensure product quality and production efficiency.

Metallurgical industry: used for screening and classifying metallurgical raw materials such as iron ore and iron powder to meet the needs of metallurgical production.

Food processing industry: suitable for screening food raw materials such as grains, condiments, food additives, etc. to ensure food safety and quality.

Pharmaceutical industry: used for screening medicinal materials, medicinal powders and other pharmaceutical raw materials to ensure the quality and purity of pharmaceutical production.

Provides high-quality, customized double-deck vibrating screens suitable for screening and classifying granular materials. Make sure to choose a manufacturer with extensive experience, a good reputation, and reliable after-sales service for quality double-deck vibrating screen equipment.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.