Used to scoop up material from a lower position and unload it at a higher position.

![]()

![]()

Price:$500.00 - $6,700.00/Set

Consult now and enjoy a 10% discount

Type: belt type

Bucket capacity: 3~102L

Bucket speed: 1.4~1.8m/s

Motor power: 5.5~7.5KW

Delivery capacity: 32-686 cubic/hour

Lifting height: 40 meters

Application: grain, feed, chemical fertilizer, limestone, calcium carbonate, dolomite, barite, talc, gypsum, diabase, quartz stone, bentonite and other powder, granular or block products

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

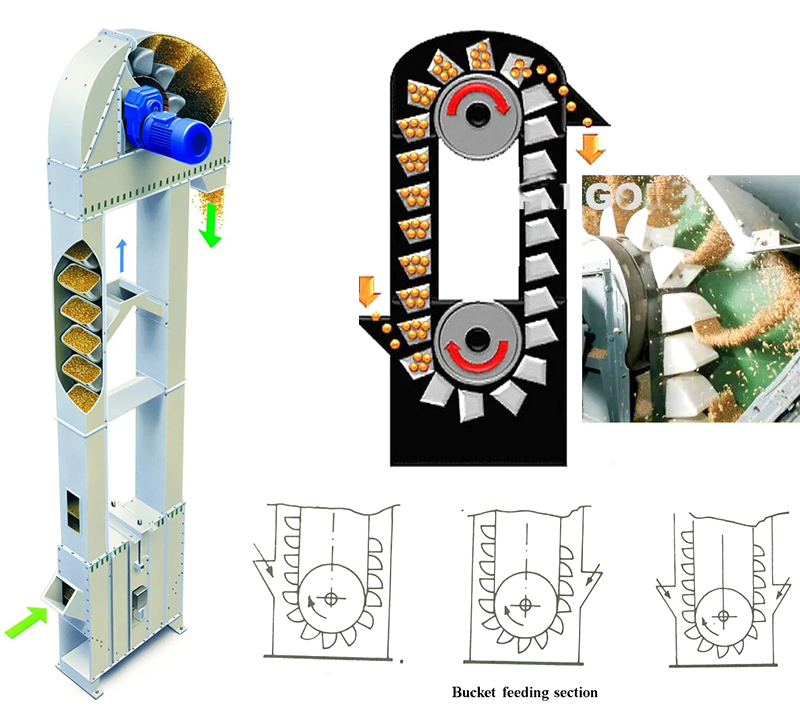

TD vertical belt bucket elevator is a type of conveyor system that is designed for the vertical transportation of bulk materials. Consists of a series of buckets attached to belts that run around pulleys or sprockets at the top and bottom of the elevator. Conveyor belts are usually made of high-strength materials such as rubber or PVC, and buckets are designed to scoop up material from a low level and discharge it at a high level.

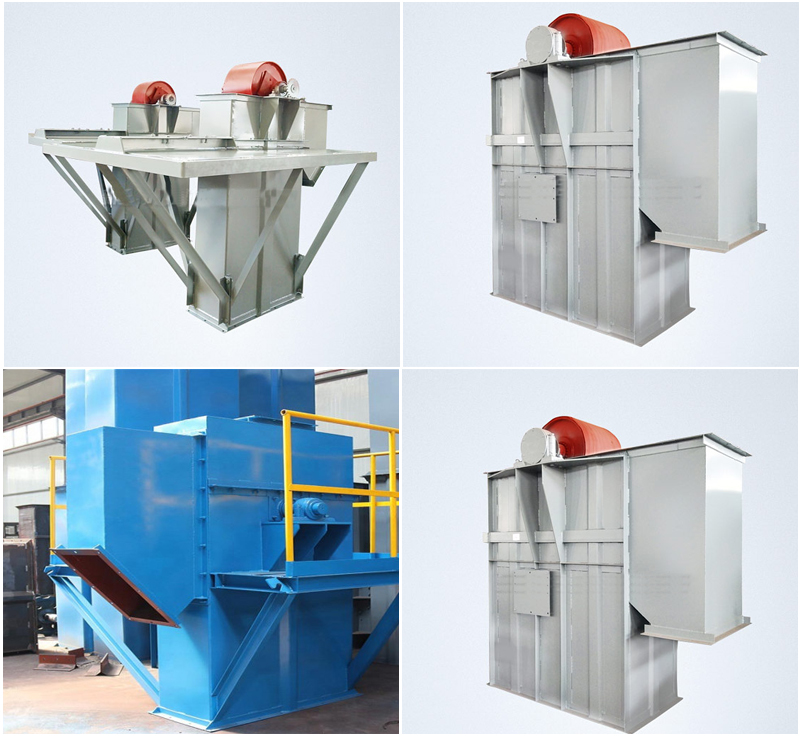

It is typically used in industries such as mining, cement, and chemical processing, where materials need to be transported vertically between different levels of a facility.

TD vertical belt bucket elevator is a versatile conveyor system for vertical conveying of bulk materials in various industries. Here are some common applications for TD Vertical Belt Bucket Elevators:

1. Mine: It is used to vertically transport coal, iron ore, copper ore and other materials between different levels of the mine.

2. Cement: Materials such as limestone, clay and gypsum are transported vertically between processing stages.

3. Chemical processing: It is used in the chemical processing industry to vertically transport fertilizers, plastics, chemicals and other materials between different stages of production.

4. Food processing: It is used in the food processing industry to vertically transport grains, nuts, seeds and other materials between different processing stages.

5. Power generation: used in power plants to vertically transport materials such as coal and biomass between different stages of the power generation process.

Material is fed into the elevator from the bottom layer. The bucket is designed to scoop up material from the bottom layer and carry it to the top layer. The belt carrying the bucket moves around pulleys or sprockets on the top and bottom of the elevator. The belt is driven by a motor and is designed to The buckets are moved in a continuous cycle, as the buckets move on the elevator, they are filled with material, the material remains in the buckets until it reaches the top level, where the buckets discharge the material into a discharge spout or chute, and the material is conveyed to the next stage of the process. The empty bucket continues to move around the bottom pulley and back to the bottom of the elevator, ready to be filled with more material.

| Model | Max Feed Size (mm) |

Capacity (Ton/Hour) |

Lifting Speed (m/s) |

Belt Width (mm) |

Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD630 | 70 | 85-142 | 2 | 700 |

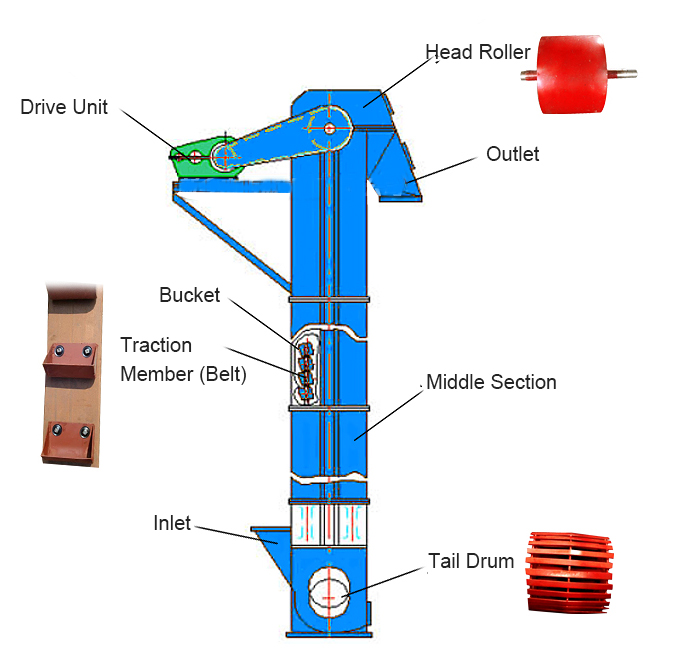

The structure of a TD vertical belt bucket elevator generally consists of the following components:

1. Head section: The head section of the elevator includes the head pulley, motor, and drive assembly. The head pulley is located at the top of the elevator and is used to drive the belt and buckets.

2. Boot section: The boot section of the elevator includes the tail pulley and tensioning mechanism for the belt. The tail pulley is located at the bottom of the elevator and is used to tension the belt.

3. Belt: The belt of the elevator is typically made of rubber, PVC, or other high-strength materials. It is used to move the buckets around the elevator in a continuous loop.

4. Buckets: The buckets of the elevator are attached to the belt and are designed to scoop up the material from a lower level and discharge it at a higher level. They are typically made of metal or plastic and come in a variety of sizes and shapes depending on the application.

5. Inspection doors: The elevator may have inspection doors located at various points along the structure to allow for easy access and maintenance.

6. Safety features: The elevator may be equipped with safety features such as sensors and interlocks to prevent overloading or other potential hazards.

TD vertical belt bucket elevators can be customized to meet the specific needs of different industries and applications. Here are some common customization options available for belt bucket elevators:

1. Belt type: The type of belt used in the elevator can be customized to meet the specific needs of the material being transported. Different belt types such as rubber, PVC, and steel can be used depending on factors such as the weight, size, and abrasiveness of the material.

2. Bucket size and shape: The size and shape of the buckets can be customized to match the material being transported and the desired capacity of the elevator. Buckets can be made in a variety of sizes and shapes, such as square, rectangular, or circular.

3. Material of construction: The buckets and other components of the elevator can be made from a variety of materials, including plastic, steel, and stainless steel. The choice of material will depend on factors such as the corrosiveness of the material being transported and the desired durability of the elevator.

4. Capacity: The capacity of the elevator can be customized to match the desired throughput of the material being transported. Elevators can be designed to handle large volumes of material at high speeds or smaller volumes at slower speeds.

5. Height: The height of the elevator can be customized to match the vertical distance between the different levels of the facility.

6. Control system: The control system for the elevator can be customized to meet the specific needs of the application. Options may include variable speed drives, programmable logic controllers (PLCs), and human-machine interface (HMI) systems.

Large volume

Because it is belt traction, there is no impact caused by chain traction due to its own structure, and the transmission is stable, so the linear speed can be increased a lot, the conveying material speed is high, and the carrying capacity is strong.

Low noise

Because the belt is used as the traction member, the stability of its transmission is not possessed by the chain bucket elevator, and there is no impact caused by the traction member, so the noise is very small.

Save space

The compact design and small footprint make it ideal for use in facilities with limited space.

Gentle handling

Can be designed to handle materials gently, reducing the risk of material being damaged or degraded during transport.

Easy to maintain

Designed for easy maintenance, it features removable lids and easy access to drives and motors.

Flexible design

Can be customized to meet the specific needs of different industries and applications, capable of handling a wide range of materials and operating conditions.

The TD hoist also has some precautions. For example, the verticality of the hoist's mechanical structure should be ensured during installation. The foundation of the motor and the reducer should be integrated. At the same time, the tightness of the connecting parts of each part should be checked regularly during use. and the lubrication of the reducer, the degree of wear of the gears and bearings in the reducer, etc., to ensure the normal operation of the hoist.

To sum up, TD vertical belt bucket elevator is a kind of mechanical equipment with stable performance, long service life, safety and reliability, which plays an important role in industrial production. As people's requirements for production efficiency continue to increase, TD hoists will also be continuously updated and improved to provide better services for various industries.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.