Rotary vibrating screen

Rotary vibrating screen Stainless steel rotary vibrating screen

Stainless steel rotary vibrating screen Double-layer rotary vibrating screen

Double-layer rotary vibrating screen Multi-layer rotary vibrating screen

Multi-layer rotary vibrating screen Ultrasonic rotary vibrating screen

Ultrasonic rotary vibrating screen

Can sieve, sort, dedust and filter a wide range of products

![]()

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Model: Φ400/600/800/1000/1200/1500/1800/2000mm

Screening area: 0.09/0.22/0.4/0.63/0.95/1.5m2

Mesh Size: 0-500 mesh

Capacity: 100-5000kg/h

Frequency: 1500rpm

Amplitude: 1~2mm

Rotary vibrating screen is also called rotary vibrating screener, used for safety screening to eliminate foreign matter, classification of different particle sizes in the same product, and the process of solid-liquid separation, using customized layered screen and powerful 3D vibration motion to pass different meshes With the external output and stackable design, this ingenious and simple machine can continuously filter up to 5 stages of product separation in just 1 operation.

Our rotary vibrating screens are available in a variety of sizes, suitable for smaller and larger scale operations from Ø400 to Ø22000, allowing throughputs from 100 to 5,000 kg/h, due to the working principle of their application being three-dimensional motion, Compared to traditional screening machines, this vibrating screen produces 3 times more vibration and provides higher throughput in ultra-fine screen meshes.

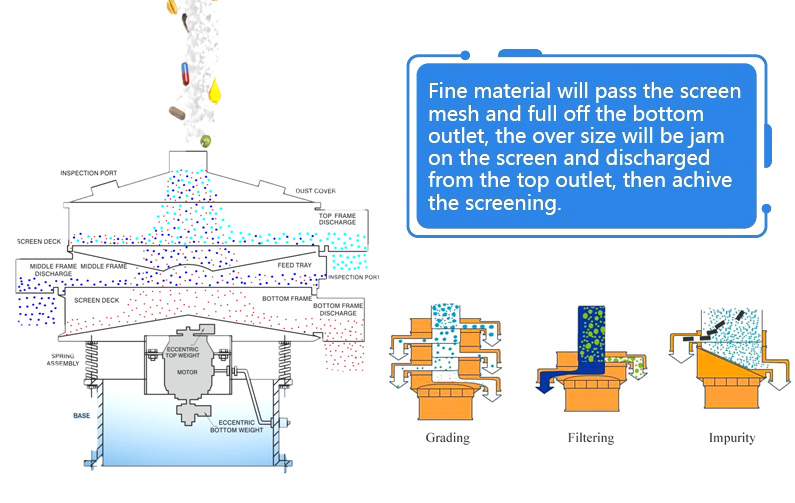

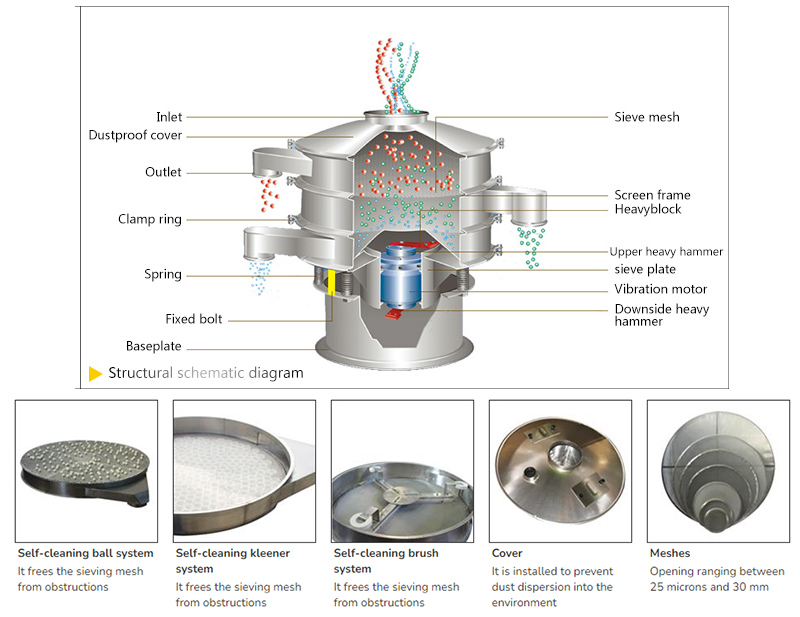

Rotary vibrating screen uses YZUL vertical vibrating motor as the excitation source. The rotating motion is converted into horizontal, vertical and inclined three-dimensional motion through the eccentric weights at the upper and lower ends of the vibrating motor, and is transmitted to the screen surface of the rotary vibrating screen; It enters the equipment through the inlet. According to different material screening requirements, the material passes through 1-5 layers of different mesh metal woven screens. In this process, the cleaning screen is located under the screens of each layer. The device (bouncing ball) continuously hits the screen through frequency vibration, so that the material on the screen can be smoothly screened through the screen, and effectively solves the problem of material blockage. The materials of different meshes pass through the screens of the corresponding meshes in each layer. Then it is discharged at the discharge port of each layer, and finally achieves the purpose of screening and removing impurities or filtering and grading. Adjusting the phase angle of the upper and lower ends can change the movement trajectory of the material on the screen surface.

Fine filter

In the rotary vibrating screen, the sieve cloth is a stainless steel wire woven mesh, and the smallest can reach 600 mesh (0.02mm). The counterweight rapid adjustment system can control and adjust the material movement on the sieve cloth, and maintain a long screening time to complete the fine screen.

high throughput

Horizontal, inclined, vertical 3D vibratory motion for higher vibrations, 3 times higher throughput through precise screening, it allows throughputs from 100 to 5,000 kg/h depending on product, mesh size and machine feed flow.

Prevents mesh blinding

Equipped with a professional screen cleaning device, the screen will not be blocked in the process of screening materials, and the screening blockage rate is less than 10%, which greatly improves the screening output and screening efficiency of the screen.

6 levels

On each shaker you can install 1 to 5 separation stages, resulting in 2 to 6 product fractions. to achieve precise particle size distribution.

No dust pollution

The rotary vibrating screen can be used in conjunction with a hose to achieve full sealing without dust, floating powder and liquid splashing. It is very suitable for sanitary production lines and dust-free workshops, and it is also very helpful to protect the health of your employees.

good adaptability

The height of the machine can be specially customized according to customer requirements. The discharge port can be placed 360 degrees, which is convenient for other equipment in the production line. It adopts IP65 protection grade motor, that is, dust and water resistance, heat resistance and oil resistance, and can deal with ultra-fine dust and liquid. Filtration separation, high and low temperature and other harsh environments.

Sieving wheat flour

Coke impurity removal

Sieving graphite powder

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

1.Various power supply voltages: 110V 220V 240V 380V 415V 450V and 550V, different power frequency, 50HZ or 60HZ, even single-phase electricity.

2.Moving wheels, observation holes, valves, magnets and frequency converters can be provided according to user requirements.

3.Labeling service and OEM orders are also available.

Rotary vibrating screen mainly includes mesh cleaning systems, damping spring, beam ring, vibration motor, seal, etc.

1.Lid with product access window.

2.Quick clamping system.

3.Screen cleaning system: a. Ultrasonic screen cleaning system. b. A brush for cleaning the sieve. c. Gaskets, lids and silicone balls.

4.The machine is mounted on wheels.

5.Machines with one, two, three or four decks.

6.0Can be customized according to user needs.

Food industry: flour, starch, milk powder, monosodium glutamate, soy milk, fruit juice, soy sauce, vinegar, etc.

Chemical industry: resin powder, washing powder, paint, soda ash, lemon powder, rubber, plastics, etc.

Pharmaceutical industry: Chinese medicine powder, Chinese and Western medicine liquid, pills, etc.

Metallurgical industry: electromagnetic materials, metal powder, electrode powder, titanium oxide, etc.

Abrasives, ceramics industry: alumina, quartz sand, mud, spray soil particles.

| Material | Proportion | Mesh(mesh) | MethodS | Capacity ((kg/hr IT/hr)) |

Model |

| Wheat starch | 1 | 2500 | Wet | 3200 IT | DH-1200-1S |

| Flour | 0.6 | 24 | Dry | 1500㎏ | DH-1000-1S |

| Soy sauce | 1 | 100 | Wet | 6500 IT | DH-1200-1S |

| Salt | 1.2 | 30/80 | Dry | 5000㎏ | DH-1500-1S |

| Corn starch | 0.6 | 40 | Dry | 1600㎏ | DH-1000-1S |

| Medicine powder | 0.8 | 80 | Dry | 550㎏ | DH-800-1S |

| PVC resin | 1 | 10 mm / 5 mm | Dry | 3000㎏ | DH-1200-2S |

| Polyethylene powder | 0.45 | 48/100 | Dry | 100㎏ | DH-800-2S |

| Graphite | 1.2 | 16/40/80 | Dry | 1400㎏ | DH-1000-3S |

| Lead powder | 11.34 | 10/80 | Dry | 1000㎏ | DH-1000-2S |

| Emery | 4 | 60 | Dry | 300㎏ | DH-1000-1S |

| Aluminum powder | 0.9/1.2 | 80/120 | Dry | 350㎏ | DH-800-2S |

| Electrode powder | 0.95 | 20/200 | Dry | 550㎏ | DH-1000-2S |

| Kaolin | 0.4 | 100 | Dry | 200㎏ | DH-1000-1S |

| Mud | 1.1 | 250 | Wet | 3200㎏ | DH-1000-1S |

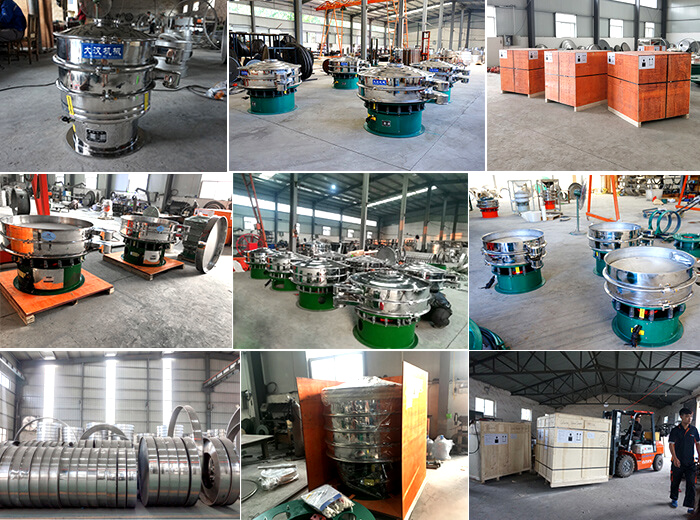

Rotary vibrating screen manufacturer has passed ISO9001 quality management system certification and EU CE certification standards. The quality is good. All models are produced and are available from stock. If our equipment is not satisfactory to you, Dahan manufacturers can also provide you for free Special custom.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.