Vibrating equipment plays a crucial role in various industries for tasks such as material handling, screening, conveying, compacting, and sorting. These machines utilize vibrations to move materials efficiently and effectively. Vibrating equipment can be classified into several categories based on their functions, design, and applications.

Inclined Vibrating Screens: These screens are designed with a multi-deck configuration and an inclined angle to facilitate the screening of materials by size classification.

Horizontal Vibrating Screens: Horizontal screens have a horizontal deck for efficient material screening and separation.

High-Frequency Vibrating Screens: These screens operate at higher frequencies to improve screening efficiency for fine particles and difficult-to-screen materials.

Electromagnetic Vibrating Feeders: These feeders use electromagnetic drives to generate vibrations, providing precise and controlled material feeding.

Grizzly Feeders: Grizzly feeders have a vibrating grizzly section at the discharge end to remove undersized materials before they reach the crusher or processing equipment.

Horizontal Vibrating Conveyors: These conveyors move materials horizontally by vibrating the trough or pan.

Vertical Vibrating Conveyors: Vertical vibrating conveyors lift materials vertically using vibrating motion for elevation or lowering.

Compaction Tables: Vibrating compaction tables are used to settle, compact, and densify materials in molds or containers to remove air bubbles and improve material density.

Sorting Tables: Vibrating sorting tables are used to separate materials based on size, weight, or other characteristics by conveying them across the vibrating surface.

Dewatering Screens: These screens are designed to remove excess moisture from materials to improve handling and processing efficiency.

Scalping Screens: Scalping screens have a coarse mesh to remove oversized materials before the primary crushing or processing stage. Sieve Shakers: Vibrating sieve shakers are used in laboratories for particle size analysis by shaking a stack of test sieves to separate particles based on size.

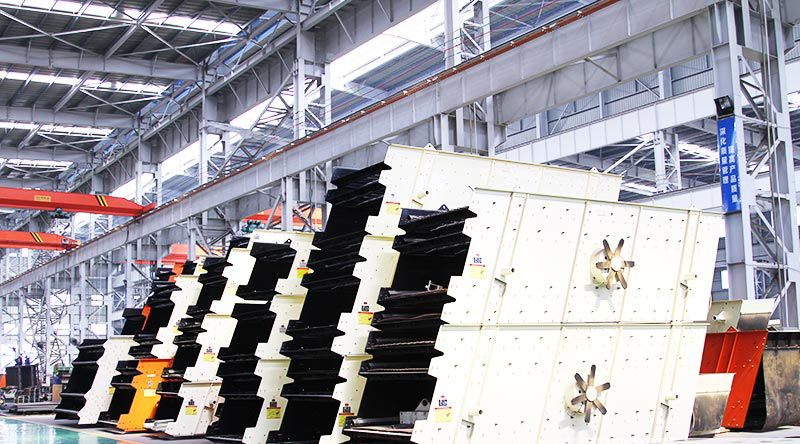

Mining vibrating screen is mainly used in mining, coal, smelting, building materials and other industries. Specific types include high-efficiency heavy-duty screen, self-centering vibrating screen, elliptical vibrating screen, dewatering screen, circular vibrating screen, banana screen, linear vibrating screen, etc. These devices can be divided into linear vibrating screens with linear motion trajectories, circular vibrating screens with circular motion trajectories, and fine screening machines with reciprocating motion trajectories according to the different running trajectories of the materials. Mining vibrating screens can be divided into single-axis vibrating screens and double-axis vibrating screens according to the form of vibrators, and according to different vibration sources, there are also inertial vibrating screens, eccentric vibrating screens, self-centering vibrating screens and electromagnetic vibrating screens.

Lightweight fine vibrating screen is suitable for screening fine materials, including rotary vibrating screens, linear screens, inline screens, ultrasonic vibrating screens, filter screens, etc. These devices are mainly used to remove lumps, packaging debris and other contaminants in products to ensure the quality of the final product.

Experimental vibrating screens are mainly used in laboratories to classify and analyze the particle size of powders, particles and suspensions, including slap screens, top-impact vibrating screens, and standard test screens. These instruments can quickly and efficiently measure solid particle size for scientific research and product quality control.

vibrating equipment encompasses a wide range of machines designed to handle different tasks in various industries. Whether it's vibrating screens, feeders, conveyors, tables, compactors, or specialized equipment for specific applications, the classification of vibrating equipment is based on their unique functions, designs, and applications to meet the diverse material handling and processing needs of different industries.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.