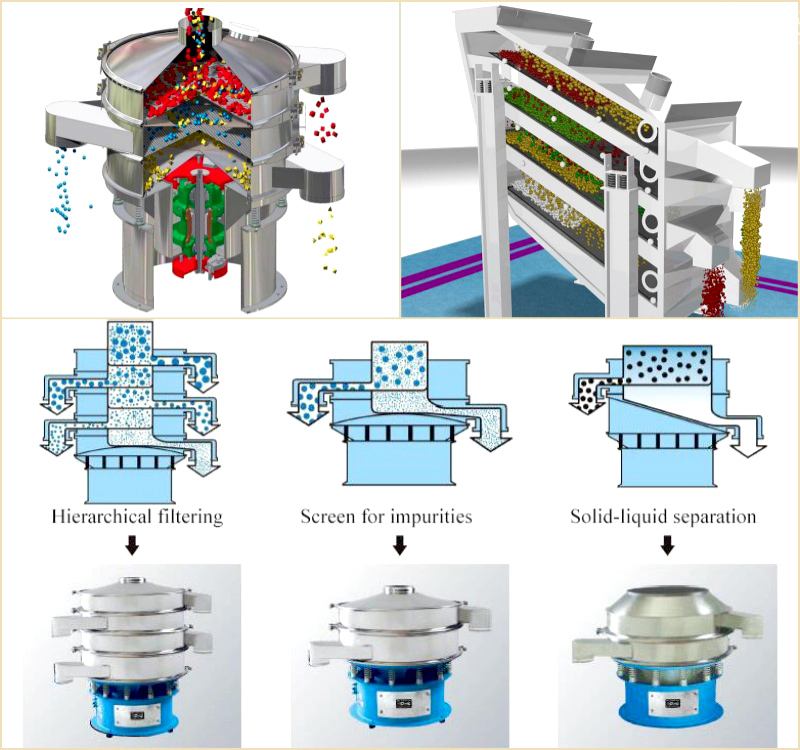

Is a machine used to separate and classify particles according to their size and shape, to protect the quality of powder or liquid products by removing oversized contaminants

![]()

![]()

![]()

Price:$500.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Diameter: 400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

Screen frame: 1-5 layers (3 layers is best)

Material: Q235 carbon steel, stainless steel 304 or 316L, polypropylene plastic

Customization: ordinary type, gate type (to control the screening time of materials), flanged type (to prevent liquid splashing), ultrasonic type (to prevent fine powder from clumping and clogging)

Application: Separation of oversized particles and foreign matter from products, as well as solid-liquid separation of liquids, fineness control of suspended particles, etc.

Commitment:

Industrial screener also known as industrial screening equipment or industrial sieving machine, is a machine used to separate and classify particles according to their size and shape, by using customized layered sieve and 3D motion to screen products, it can be used Suitable for screening dry powder or granular products as well as wet products and liquids, it can eliminate foreign matter in products through continuous filtration, only 1 operation can be used for separation of up to 5 grades of products, usually used in various industries, such as mining, food And beverage, pharmaceutical, chemical and recycling etc.

Industrial screener can choose single-layer or multi-layer screen, and can grade up to 6 different specifications of products at one time, machine diameter: 400, 600, 800, 1000, 1200, 1500 or 1800mm, different sizes and options are available, Meet your screening requirements.

Vibro Sifter

Used for screening of raw materials and final production inspection of finished products, it can remove agglomerates and contaminants from products, and can provide up to 5 grades of classification in one operation, suitable for screening from 36 microns to 25 mm.

Ultrasonic Vibrating Screen

Applying ultrasonic frequency to the sieve can separate 20m (#635 mesh) fine powder, suitable for high viscosity, high electrostatic fine powder, the screening accuracy can be increased by more than 80%, and the output can be increased by 2-5 times.

Tumbler Screen

Simulating the action of manual sieving, it produces a three-dimensional rolling motion of horizontal and throwing, which is suitable for fine-grained materials within 500 meshes. The screening accuracy is increased by 90-95%, and the output is 5-10 times that of circular vibrating screens.

Filter Sieve

It is often used in the liquid filtration industry to remove unwanted particles in liquid or suspended matter, and of course it can also be used as a powder to remove impurities. It can be used in factories or small workshops with small processing volume.

Linear Vibrating Screen

Used for screening, classifying, deblocking, dewatering any lumpy solids or slurries, multi-layer systems can separate the product into 2-7 different parts, in Multi-stage separation is completed while removing impurities.

The vertical vibrating motor is used as the excitation source, and the eccentric weights at the upper and lower ends of the vibrating motor convert the rotary motion into a three-dimensional motion of horizontal, vertical and inclined, and transmit it to the screen surface of the industrial screen, and the material enters through the feeding port In the equipment, according to different screening requirements, the material passes through 1-5 layers of screens with different meshes. It can screen smoothly and effectively avoid the problem of material blocking. The material close to the sieve aperture passes through the sieve and is the undersize material. The material larger than the sieve aperture is discharged from the outlet of the layer and is the sieve. Substances, to complete the purpose of screening or filtering.

Efficient screening

Designed to efficiently separate and classify particles according to their size and shape. This allows for a more accurate and efficient screening process.

Great productivity

It allows throughputs from 100 to 3300 kg/h, depending on the product, mesh size and feed flow of the machine.

Improve quality control

This ensures that particles of the desired size and shape are correctly separated and sorted, helping to improve quality control.

Cost effective

It can be a cost-effective solution for various industries by reducing labor costs and increasing efficiency.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

To suit different applications and material requirements, industrial screeners can be customized in many ways. Here are some examples of industrial screener customization options according to different industries:

1. Food and beverage industry: In the food and beverage industry, food-grade materials and finishes, such as stainless steel, can be customized to meet safety and hygiene requirements. They can also be designed with different sieve plates and screen media to handle different food products such as powders, granules and liquids.

2. Pharmaceutical industry: Pharmaceutical-grade materials and finishes can be customized, such as stainless steel and polished surfaces, to meet safety and hygiene requirements. They can also be designed with different frits and screen media to handle different pharmaceutical products such as powders, granules and tablets.

3. Chemical industry: In the chemical industry, materials and finishes that are resistant to aggressive chemicals and solvents can be customized. They can also be designed with different sieve decks and screen media to handle different chemical products such as powders, granules and liquids.

4. Mining industry: In the mining industry, heavy-duty materials and surface treatments, such as high-strength steel and anti-rust coatings, can be customized to withstand harsh operating conditions. They can also be designed with different sieve decks and screen media to handle different types of minerals and ores.

5. Recycling industry: Recycling materials can be used in the recycling industry for customization of wear-resistant materials and finishes. They can also be designed with different screen decks and screen media to process different types of recycled materials such as plastic, metal and paper.

Industrial screener is usually suitable for cement, fertilizer, paper or food industries, suitable for dry and wet screening of various industries related to particles and powders, such as metallurgy, non-ferrous metals, non-ferrous metals, food, abrasives and other industries.

We are a supplier specializing in the manufacture of industrial screening machines, with many years of production experience and technology accumulation. We provide screening machines of various specifications, including vibrating screens, centrifugal screens, high-frequency screens, etc., which can meet the screening needs of different industries. Our products are of good quality and reasonable price, and are often chosen as the first choice by customers in various industries. In addition, we also provide a variety of customized services to meet the individual needs of customers. We always uphold the principle of customer first and wholeheartedly provide customers with high-quality products and services. If you need industrial screening machines, welcome to contact us, we will try our best to serve you.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.