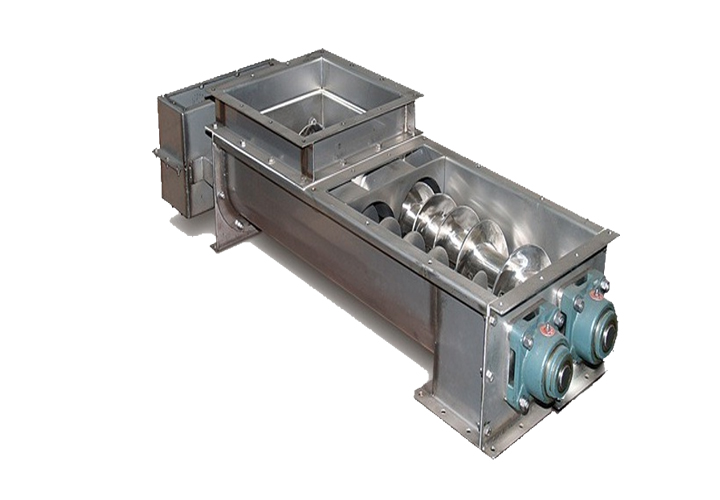

Twin screw feeder

Twin screw feeder Twin shaft auger feeder

Twin shaft auger feeder Twin shaftless auger feeder

Twin shaftless auger feeder Tapered twin shaft screw feeder

Tapered twin shaft screw feeder Stainless steel twin screw feeder

Stainless steel twin screw feeder

Twin screw design with mixing and stirring functions for free-flowing powders and fine particles, ideal for feeding difficult materials

![]()

![]()

![]()

Price:$700.00 - $40,000.00/Set

Consult now and enjoy a 10% discount

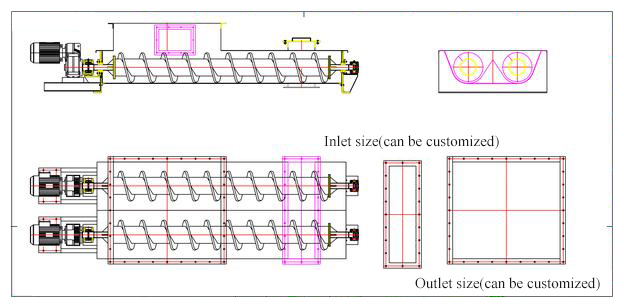

Type: Twin shaft / twin shaftless

Conveying length: 10-20 meters

Conveying output: 134m³/h

Conveying speed: 1.5m/s

Power: 1.1-55KW

Material:

Applications: Conveying heterogeneous materials (wood chips, paper, etc.), materials in the flour processing industry (bran, flour, etc.) and bridging materials (eg sawdust, soybeans, etc.)

Twin screw feeders are an option for users who need particularly efficient discharge/feed from bins or hoppers, they are designed for handling inhomogeneous materials (wood chips, paper, etc.), materials in the flour milling industry (bran, flour, etc.) and bridging materials (such as sawdust, soybeans, etc.). Twin screw feeder is generally used for horizontal conveying of materials, suitable for feeding under the silo.

Twin shaft screw feeder-mainly suitable for cement, coal, stone, and other granular or powdery materials that are not sticky and will not stick to the inner center shaft of the WLS screw conveyor.

Twin shaftless screw feeder-mainly used for materials with strong adhesion in conveying stations in industries such as environmental protection, papermaking, chemical industry, food, medicine, beverage, etc., paste-like viscous materials (such as chemical raw materials, waste paper pulp, malt, sludge, etc.) and In industries that are easy to wind up (such as domestic waste), the main reason is that the shaftless screw conveyor has the characteristics of anti-winding and anti-winding.

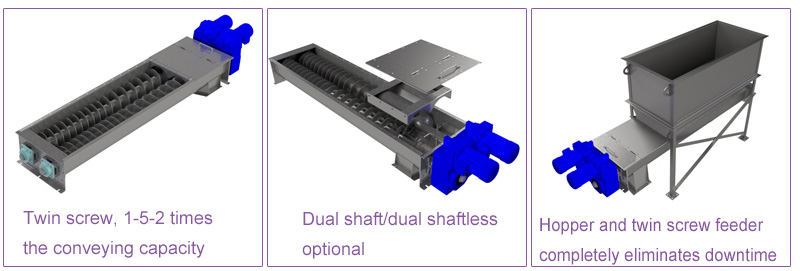

Twin screw feeder is equipped with a solid spiral in two seamless steel tubes, one of which is left-handed and the other is right-handed. When working, the two helices rotate through a pair of gears at the shaft extension position, and the material is moved axially due to the rotation of the helix, so as to achieve the purpose of conveying.

Twin screw feeder includes feeding trough body, driving device, head bearing, tail bearing, casing, frame, etc. One end of the discharge port of the feeding trough body is higher than one end of the feeding port, and the feeding trough body forms an included angle with the horizontal direction. Two parallel screws are arranged inside, bearings are installed at both ends of the screws, and screw blades are respectively fixed on the screws. The working process includes the steps of conveying and mixing, which saves the stirring and mixing steps in the traditional process. The design of the twin-screw increases the internal space of the feeding trough and the material carrying capacity, which increases the conveying capacity of the entire screw conveyor, greatly improves the work efficiency, and the mixing effect is better than conventional mixing.

| Specification | Main technical performance | Drive device | Drive device | Weight(kg) | |||

| Diameter | Length(m) | Yield( t/h) | Rotating speed(min) | Reducer | Electric motor | ||

| Model | Speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

Large delivery volume

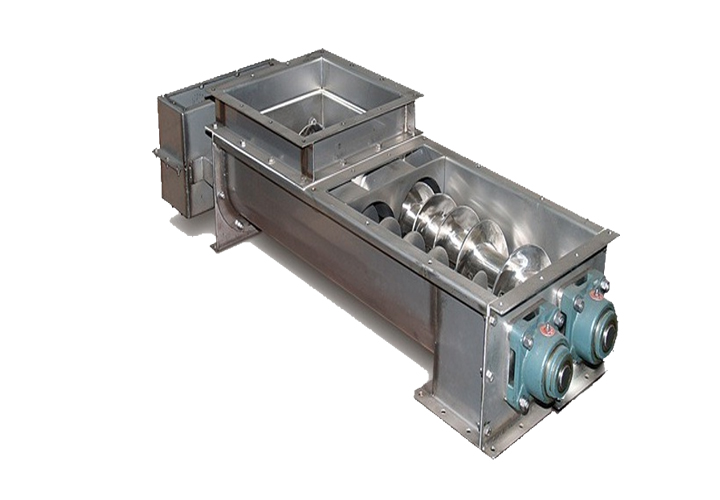

The two screws rotate through a pair of gears at the shaft extension position. In addition to conveying materials, they also have the functions of mixing, stirring, and pushing materials. The conveying capacity is 1.5-2 times that of the single-shaft screw conveyor.

Not easy to block

The two seamless steel pipes are respectively equipped with solid screws, and the screw shafts on both sides turn to different directions, which can avoid the phenomenon of material blocking caused by material accumulation.

Low cost

The twin screw feeder increases the mixing speed when working, which is equivalent to the mixer mixing materials at the same time, but the price is lower than that of the mixer, which saves costs.

Long service life

The variable diameter structure can greatly increase the volume of the hanging bearing, prevent the friction between the hanging bearing and the material, and the service life can reach more than 2 years.

1. Twin screw feeder is that the screw shafts on both sides turn in different directions. The specific mixing and stirring function. When the material is put into the feeding port, it will automatically rotate the material to the middle and mix it together. No matter which direction the single screw feeder runs, the mixing and stirring functions are not specified.

2. At the same rotational speed, because the helix angle of the double blade is higher than that of the single blade, the conveying flow of the double blade is larger than that of the single helical blade. The conveying capacity is 1.5-2 times that of a single screw.

Twin screw feeder is the choice of users who need particularly efficient unloading/feeding from silos or hoppers. It usually works horizontally and is suitable for feeding under the silo. It is suitable for conveying the kind of poor flow performance, large object volume or size Materials that need to be stirred, such as heterogeneous materials (wood chips, paper, etc.), materials in the flour processing industry (bran, flour, etc.) and bridging materials (such as sawdust, soybeans, etc.), due to the design of the double helix shaft, It is equivalent to a mixer mixing materials at the same time, but the price is lower than that of the mixer, saving costs.

Application:

1. It can be directly installed in the slag removal equipment or sludge dewatering equipment, and then made into a sealed structure for conveying and pressing, which can collect and improve the environment, reduce the amount of slag, and facilitate subsequent processing.

2. It is designed for feeding straw to the boiler furnace. The spiral blade is used to achieve the effect of uniform feeding, and it has the functions of mixing and stirring.

In order to achieve uniform mixing of materials and adjust the feeding rate, the drive of this system is an electromagnetic speed-regulating motor or a frequency converter, which can easily adjust the speed of the screw conveyor, so that it can be in the best state. Meet the delivery requirements.

Twin shaft screw feeder for sludge

Twin shaftless screw feeder for clay

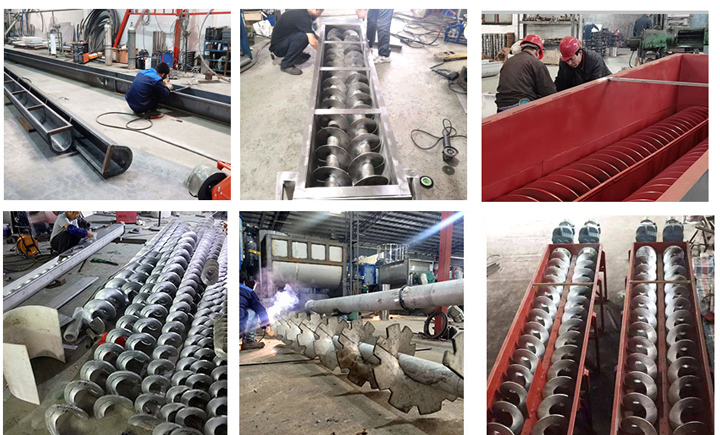

Dahan Machinery has been established for 15 years. The twin screw feeder model is complete and relevant accessories are provided. All links are independently constructed by the company without subcontracting. There are many disputes and high costs. The integrated and rapid construction is completed by the installation team in one stop. The team is unified to reduce rework and ensure the quality of the project. The products are delivered on the same day or the next day, shortening the construction period and reducing the waiting time of customers.

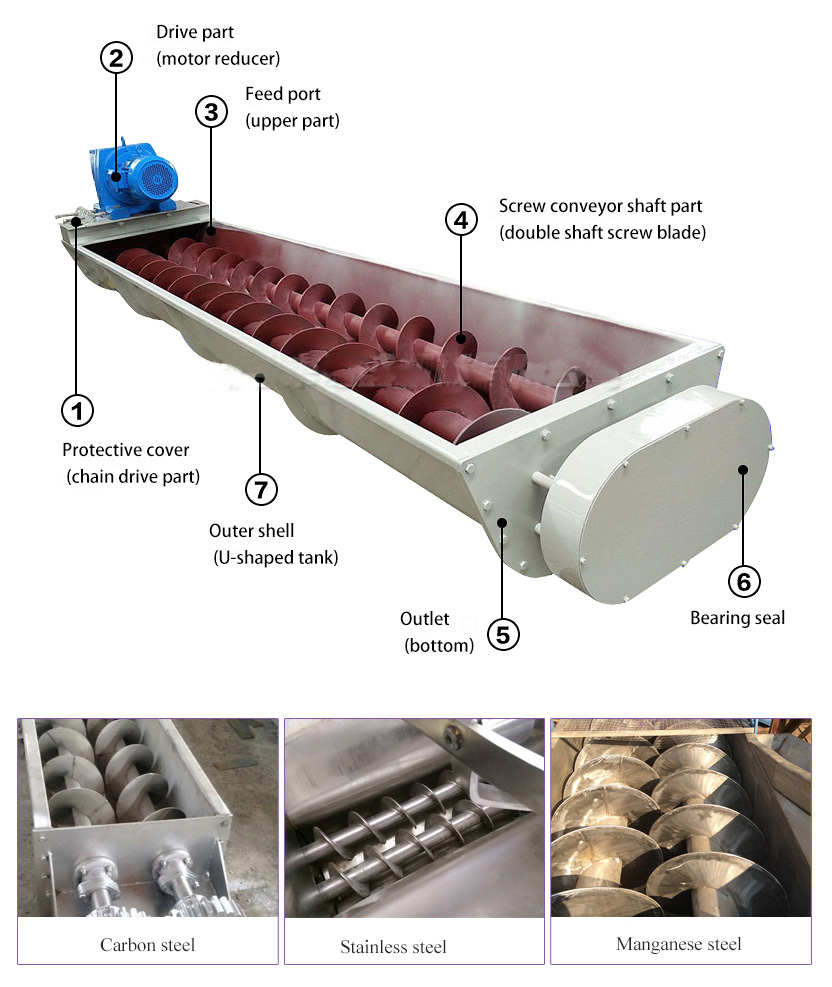

The specifications of this product are (single shaft, no shaft), shell blade material: carbon steel, stainless steel. According to the particle size, conveying volume and conveying distance of the conveyed material, reasonable selection and design can be made to achieve no jamming, no arching, and smooth discharge. Parameters and drawings are provided free of charge.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.