Twin screw feeders, also called twin shaft screw feeders, are used to handle heterogeneous materials (wood chips, paper, etc.), materials in the flour processing industry (bran, flour, etc.) and bridging materials (eg sawdust, soybeans, etc.). This article will give you a comprehensive introduction to the twin screw feeder, hoping to help you.

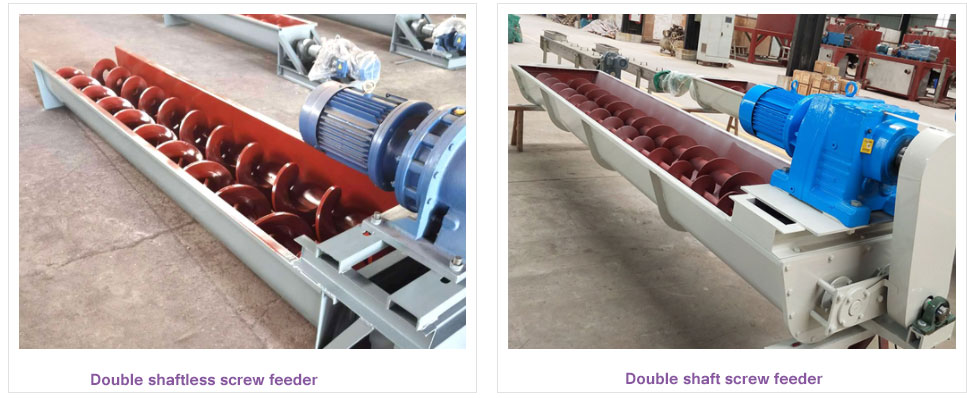

twin screw feeder is divided into two types: double shaft and double shaftless.

Double shaft screw feeder: It can transport materials that are not easy to stick and have a certain friction, and have certain requirements for the wear resistance of the screw feeder.

Double shaftless screw feeder: It can transport granular/powder/wet/paste, semi-fluid/viscous materials, such as sludge, household waste, etc. It is also suitable for materials with special hygiene requirements.

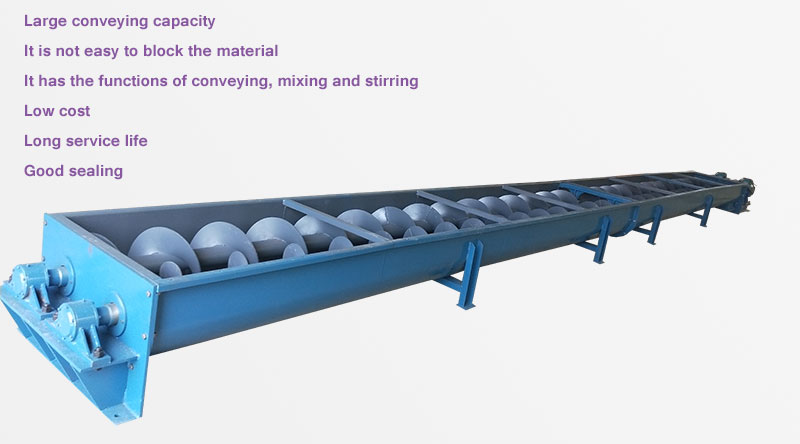

1. Large conveying capacity

The two screws rotate through a pair of gears at the shaft extension position, and the conveying capacity is 1.5-2 times that of the single-shaft screw feeder.

2. It is not easy to block the material

The two seamless steel pipes are respectively equipped with solid screws, and the screw shafts on both sides turn to different directions, which can avoid the phenomenon of material blocking caused by material accumulation.

3. It has the functions of conveying, mixing and stirring

In addition to conveying materials, it also has functions such as mixing, stirring, and pushing materials. It is suitable for conveying materials with poor fluidity, large volume or particle size and need to be stirred.

4. Low cost

When the twin screw feeder is working, the mixing speed is increased, which is equivalent to the mixer mixing materials at the same time, but the price is lower than that of the mixer, and the cost is saved.

5. Long service life

The variable diameter structure can greatly increase the volume of the hanging bearing, prevent the friction between the hanging bearing and the material, and the service life can reach more than two years.

6. Good sealing

All bearings are sealed with multi-layer sealing boxes, and the materials will not overflow and will not be polluted by other dust.

The twin screw feeder is mainly used to convey the materials with poor flow performance, large volume or size, and need to be stirred. It usually works in the horizontal direction. Suitable for feeding under silo. Used in metallurgical building materials, chemical industry, food machinery and other industries. The processing industry is widely used.

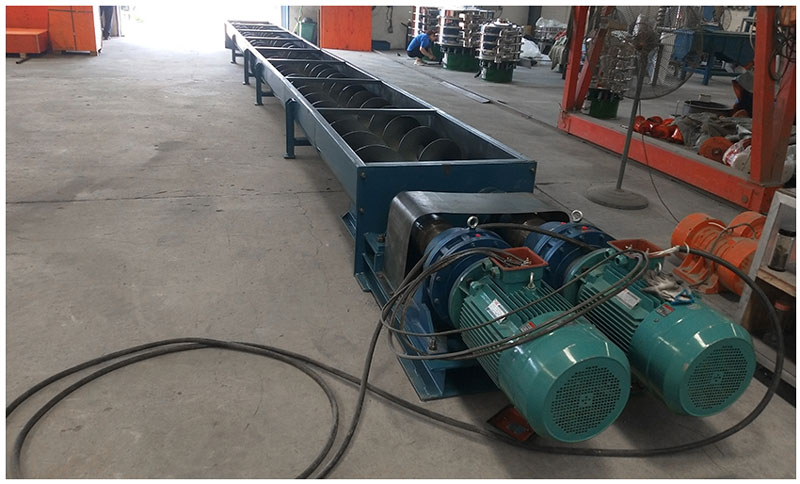

The following is a scene case picture about the twin screw feeder:

Address:China,Yanjin county forest park gate to the west 1000 meters north road.