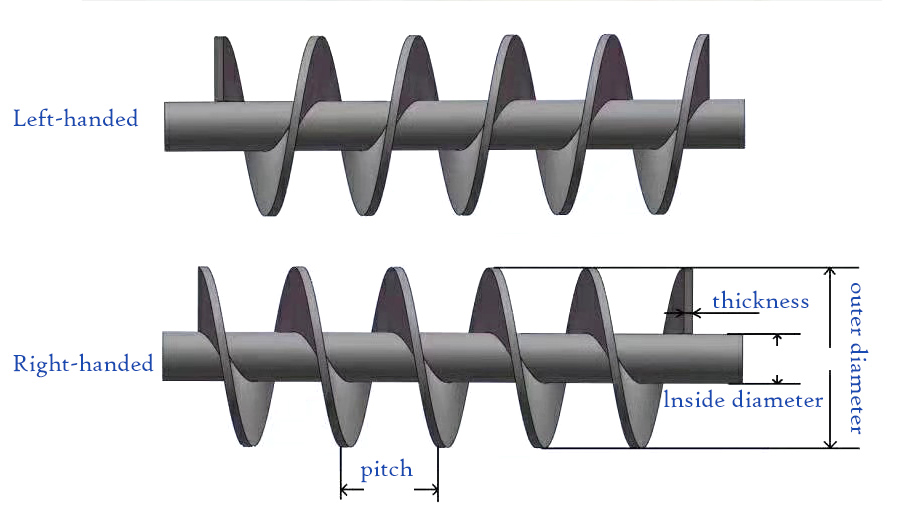

The twin screw feeder uses two seamless steel tubes with a solid spiral, one of which is left-handed and the other is right-handed. What are the structural characteristics of the twin screw feeder? The following is the relevant introduction:

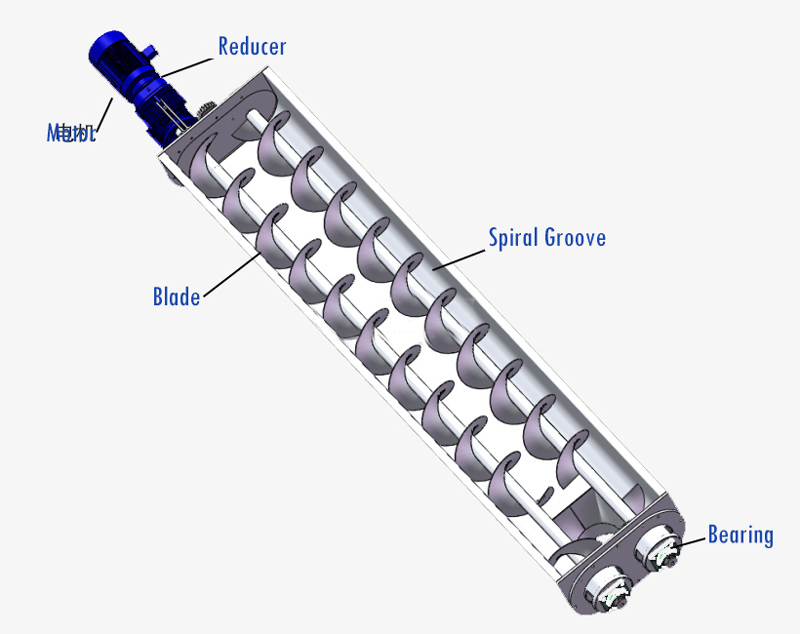

1. Twin screw feeder blade structure

The design of twin screw feeder blade structures can vary depending on the specific application and the material being conveyed. Some common features of blade structures include:

Lead screw pitch: It is the distance between the screw threads, which is an important factor to determine the capacity and efficiency of the twin-screw feeder. A larger pitch will result in a higher capacity, but may require more power to operate.

Screw diameter: The screw diameter is the width of the screw. This is another factor that affects the capacity and efficiency of a twin screw feeder.

Screw flight design: The screw flight is the raised portion of the screw that forms a pocket for the material to be transported. Flight designs can vary depending on the material being transported and the flow characteristics required. Common flight designs include variable pitch, tapered, and cut-fold.

Screw Material: Usually made of stainless steel or other durable material that can withstand the wear and tear of continuous operation.

2. The rotation axis determines the material conveying direction

The rotation direction of the rotating shaft of the twin screw feeder determines the conveying direction of the material. Generally, the twin screw feeder is designed according to a single item, and the reverse conveyance of the rotating blades designed for conveying will reduce the service life of the conveyor.

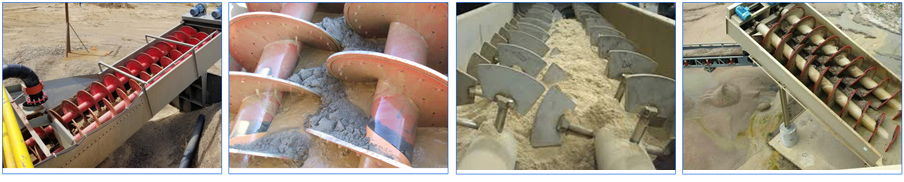

3. Double shaft design increases the conveying capacity

Compared with the single-shaft screw conveyor, at the same speed, the twin screw feeder has a higher helix angle than the single screw blade, so the conveying flow of the blade per unit time is larger, and the conveying volume has been increased to the original single screw. 1.5-2 times as much.

Summary: Compared with other conveying equipment, twin screw feeder has the advantages of small cross-sectional size, good sealing performance, stable and reliable operation, multi-point loading and unloading in the middle, safe operation, and simple maintenance.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.