Designed to efficiently load and unload cargo or materials from a truck or trailer.

![]()

![]()

Price::$900.00-$5,400.00/Set

Consult now and enjoy a 10% discount

Belt width: 400-1200mm

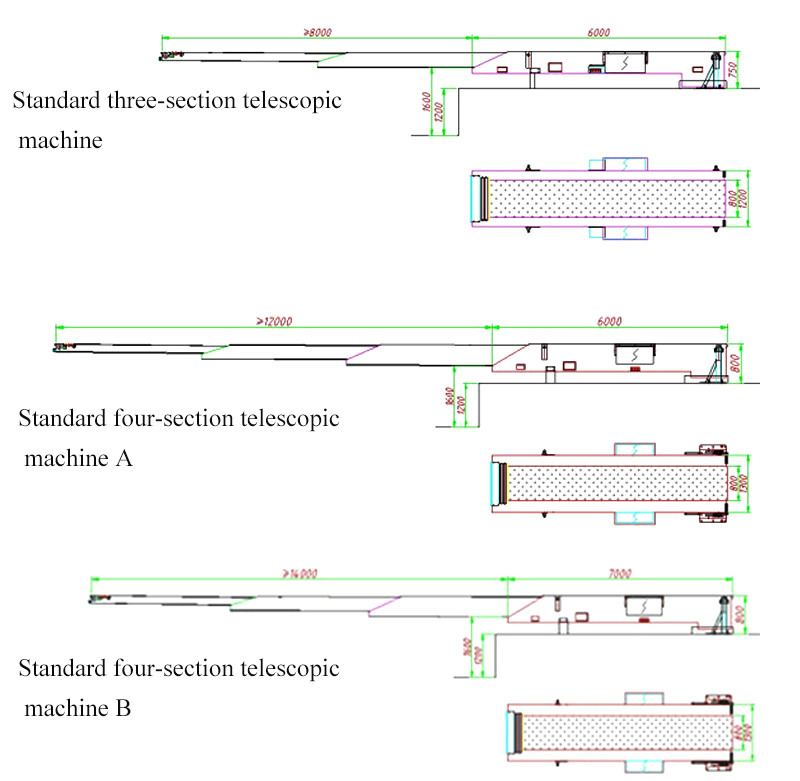

Fixed length: 3-26 meters

Extended length: 2.8-14 meters (can be customized)

Number of conveyor sections: two-section, three-section, four-section

Capacity: 50-400T/H

Power: 8.5KW-18KW (depending on the length)

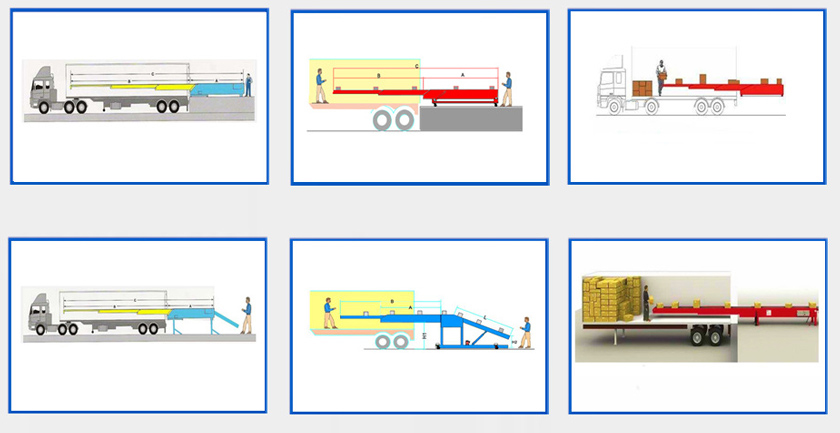

Application: Commonly used in warehouses, distribution centers, shipping yards and other logistics facilities to streamline the truck loading and unloading process.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Truck loading unloading belt conveyor is a specialized conveyor system designed to facilitate the efficient loading and unloading of goods or materials onto or from trucks or trailers. It is commonly used in various industries, including logistics, warehouses, distribution centers, and manufacturing facilities.

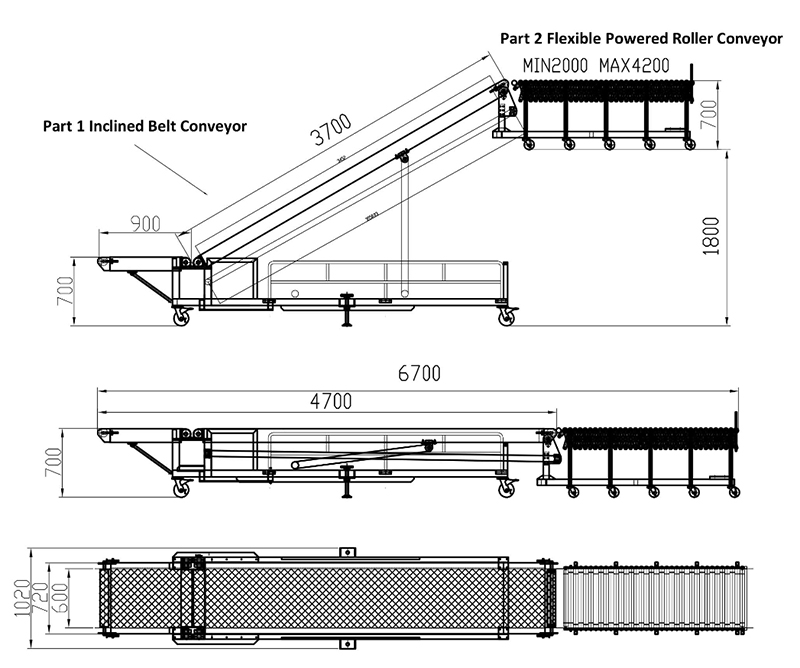

The truck loading/unloading belt conveyor typically consists of a continuous belt that runs along a series of rollers or pulleys, supported by a frame structure. The conveyor is positioned at the loading or unloading dock, allowing for the seamless movement of goods between the truck and the facility.

Hydraulic Truck Loading Unloading Belt Conveyor

Hydraulic truck loading unloading belt conveyor uses a hydraulic system as the power source, and uses a hydraulic cylinder to drive the lifting and expansion of the conveyor belt. It has the characteristics of easy operation and good stability.

Non Hydraulic Truck Loading Unloading Belt Conveyor

Non hydraulic truck loading unloading belt conveyor usually uses an electric motor or other power source to drive the operation of the conveyor belt. It does not involve a hydraulic system and is suitable for some occasions that do not require hydraulic devices.

Truck loading/unloading belt conveyors find application in various industries and scenarios where efficient and streamlined transfer of goods between trucks and facilities is required. Some common applications include:

Logistics and Distribution Centers: Truck loading/unloading belt conveyors are extensively used in logistics and distribution centers for loading and unloading trucks carrying goods or parcels. They enable efficient and rapid transfer of packages, reducing manual labor and optimizing operational efficiency.

Warehouses: Belt conveyors are employed in warehouses to facilitate the loading and unloading of goods from trucks. They help in the smooth flow of materials between the trucks and the storage area, improving productivity and reducing handling time.

Construction Sites: Construction projects often involve the transportation of materials and equipment to and from the site using trucks. Loading/unloading belt conveyors are used to efficiently transfer construction materials such as aggregates, cement, bricks, and equipment onto or from trucks, enhancing productivity and reducing manual labor.

Ports and Terminals: Ports and terminals handle large volumes of cargo transported by trucks. Truck loading/unloading belt conveyors are used to transfer containers, palletized goods, or bulk materials between trucks and ships or warehouses, ensuring smooth logistics operations.

Recycling and Waste Management: Belt conveyors play a crucial role in recycling and waste management facilities. They are used to load or unload trucks carrying recyclable materials or waste, facilitating the sorting and processing of materials for recycling or proper disposal.

Food Processing and Beverage Industries: Truck loading/unloading belt conveyors are employed in food processing and beverage industries to transfer raw materials, packaging materials, or finished products between trucks and production areas. They ensure hygienic and efficient handling of goods, complying with industry standards.

Truck loading and unloading belt conveyors work with a continuous belt that runs along a series of rollers or pulleys and is supported by a frame structure. Here is a step-by-step explanation of how these conveyors typically work:

Conveyor Positioning: Truck loading belt conveyors are located at loading docks and can be fixed in place or as mobile units. It aligns with the truck or trailer for seamless transfer of goods.

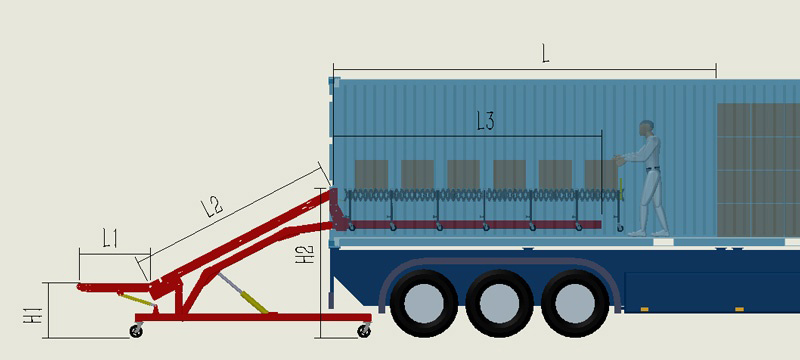

Adjust Conveyor Height: Adjust conveyor height to match truck bed level. This ensures that goods can be transferred smoothly between the truck and the conveyor without any noticeable height differences.

Starting the conveyor: The conveyor can be started manually or by automatic control. When activated, the motor drives the pulley or pulley, causing the belt to move continuously.

Loading or unloading goods: goods or materials are placed on the conveyor belt at the loading point or transferred from the truck to the conveyor belt. The continuous motion of the belt carries the goods along the length of the conveyor.

Unloading or receiving goods: At the point of unloading, the goods are either transferred directly to the receiving area or onto another conveyor system for further processing or distribution. Conveyor belts can be designed to unload goods in specific ways, such as onto chutes or into containers.

Versatile Design

These conveyors are designed to handle a wide range of materials, including packages, boxes, cartons, bags, and pallets. They offer flexibility in loading and unloading various types of goods.

Adjustable Height and Length

The height and length of the conveyor can be easily adjusted to match the truck or trailer height, ensuring seamless loading and unloading operations.

Increased Productivity

Truck loading and unloading belt conveyors help optimize workflow and increase productivity by reducing the time required for loading and unloading operations. This leads to faster turnaround times for trucks and improved operational efficiency.

Space Optimization

Truck loading and unloading belt conveyors are typically compact and can be easily maneuvered in tight spaces. They enable efficient space utilization within the loading and unloading area.

Customizable Options

These conveyors can be customized with additional features such as telescopic sections, adjustable incline or decline angles, and integrated weighing or scanning systems, based on specific operational requirements.

Integration with Other Equipment

They can be seamlessly integrated with other material handling equipment such as forklifts, palletizers, and sorting systems, creating a comprehensive and efficient loading and unloading process.

The capacity of a truck loading unloading belt conveyor depends on its design and specifications, and can usually be customized according to demand. Generally speaking, the capacity of a truck loading unloading belt conveyor can range from tens of tons to hundreds of tons. This type of equipment is usually used to efficiently load and unload large quantities of bulk materials, such as ore, coal, grain, etc., to improve loading and unloading efficiency and reduce labor costs. It is suitable for places such as ports and warehouses that require large amounts of material loading and unloading. Choosing a truck loading unloading belt conveyor with the right capacity will help improve production efficiency and reduce loading and unloading time.

| Type | section | Fixed Length (A) | Extension length (B) | Total Length (C) | Belt Length (W) |

| DH-2-6A/4B | 2 | 6000 | 4000 | 10000 | 600/800 |

| DH-3-5A/7B | 3 | 5000 | 7000 | 12000 | 600/800 |

| DH-3-6A/8.6B | 3 | 6000 | 8600 | 14600 | 600/800 |

| DH-4-5A/10B | 4 | 5000 | 10000 | 15000 | 600/800 |

| DH-4-6A/12.6B | 4 | 6000 | 12600 | 18600 | 600/800 |

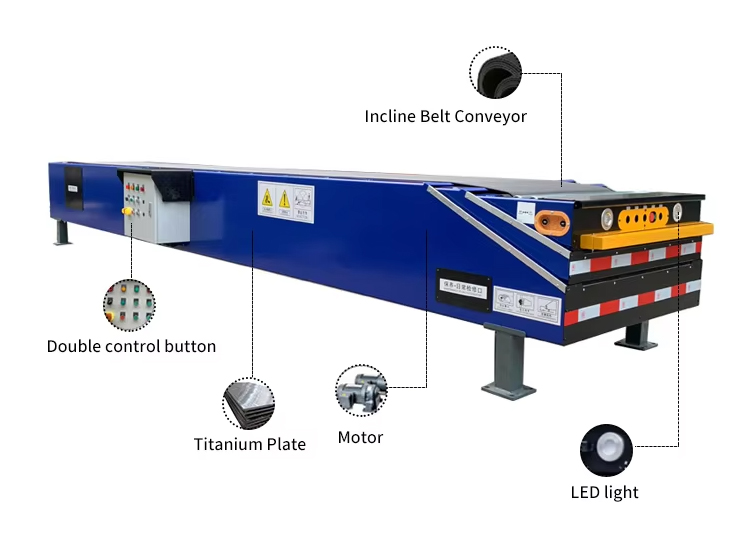

Truck loading and unloading belt conveyor usually consists of the following basic components:

Drive device: used to start the belt conveyor, including motor, reducer, drive shaft, etc.

Conveyor belt: The belt used to carry the product has different materials including PVC material, rubber material, etc.

Roller: Directly drive the conveyor belt, which can change the running direction of the conveyor belt.

Frame: load-bearing frame, used to support the entire conveyor.

Tensioning device: spring or hydraulic device, used to maintain the tension of the conveyor belt to prevent slipping.

Unloading device: flap, scraper, etc., different unloading methods can be selected according to the characteristics of the material.

Control system: PLC, frequency converter, etc.: control the start, stop, speed adjustment, etc. of the conveyor.

Selecting the correct truck loading and unloading belt conveyor requires consideration of a variety of factors to ensure that the conveyor system meets your specific requirements. Here are some key considerations to help you make an informed decision:

Application Requirements: Define the specific needs of your application. Consider factors such as the type and weight of cargo being handled, required loading/unloading rates, available space, and any special requirements unique to your operation.

Load capacity: Determine the maximum weight and size of the load to be transferred. Make sure the conveyor's load capacity meets or exceeds your requirements. Consider static loads (when the cargo is at rest) and dynamic loads (when the cargo is in motion).

Conveyor Length and Width: Evaluate the conveyor length and width needed to accommodate the trucks and desired loading and unloading areas. Consider the size of the truck or trailer you will be using and make sure the conveyor can efficiently reach the entire truck bed.

Adjustable height and reach: If you handle trucks of different heights, consider a conveyor with adjustable height and telescoping or articulation features. This will allow you to adapt the conveyor to different truck sizes and configurations.

Speed and control: Determine the required speed and necessary control of the conveyor belt. Consider whether you need variable speed control or specific controls to start, stop or reverse your conveyor. Automation and integration with other systems may also be important considerations.

Generally, the inclination angle of the truck loading and unloading belt conveyor is between 0°~45°.

0°~18°: Suitable for most bagged or box conveying, which is a common inclination angle.

18°~30°: Suitable for conveying materials with higher density or when a higher lifting height is required.

30°~45°: Suitable for conveying materials with smaller particles and lower density, or when conveying in a narrow space.

A large logistics company introduced a truck loading unloading belt conveyor to improve loading and unloading efficiency. The belt conveyor can quickly transport bulk materials from the truck to the designated location in the warehouse, reducing manpower requirements and improving operating efficiency. By automating the loading and unloading process, the time is greatly shortened and the overall logistics operation efficiency is improved. This solution not only saves costs, but also improves working conditions, making logistics operations more efficient and safer.

The selection of a suitable truck loading and unloading belt conveyor needs to be combined with the type of conveyed material. The following are selection suggestions based on the characteristics of different material types:

Bagged materials: You can choose a belt conveyor with a smaller inclination angle to avoid sliding and accumulating materials during transportation.

Granular materials: It is suitable to choose a belt conveyor with a certain inclination angle and strong conveying capacity.

Block materials: It is recommended to choose a belt conveyor with a larger inclination angle and strong conveying capacity to meet the conveying needs of block materials.

Special considerations: The structural strength and wear resistance of the conveyor need to be considered to cope with the impact and wear of block materials.

Flammable and corrosive materials: For special materials, it is necessary to choose a belt conveyor with special requirements such as corrosion resistance and explosion-proof.

As a source manufacturer, we support non-standard customization and can provide you with professional design services based on your conveying conditions to ensure that your conveying efficiency can be maximized during the conveying process. In addition, we have a professional after-sales and pre-sales team that can quickly solve your doubts. If you need it, please feel free to contact us!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.