Mobile belt conveyor

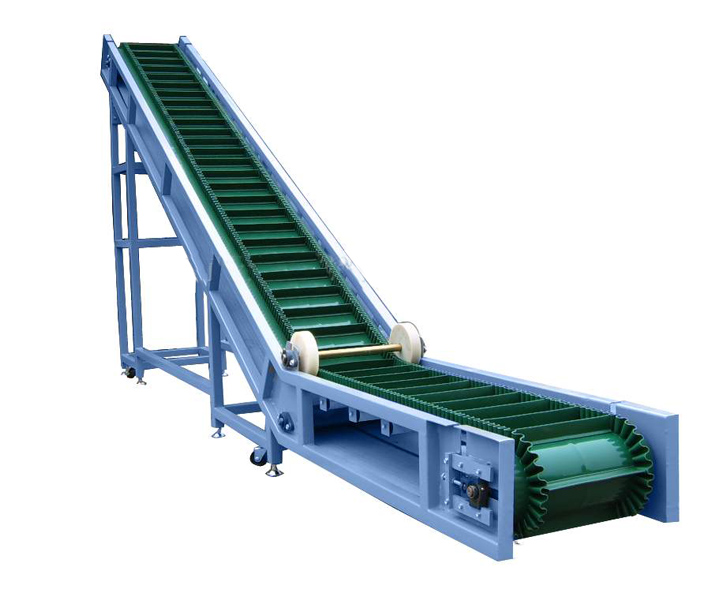

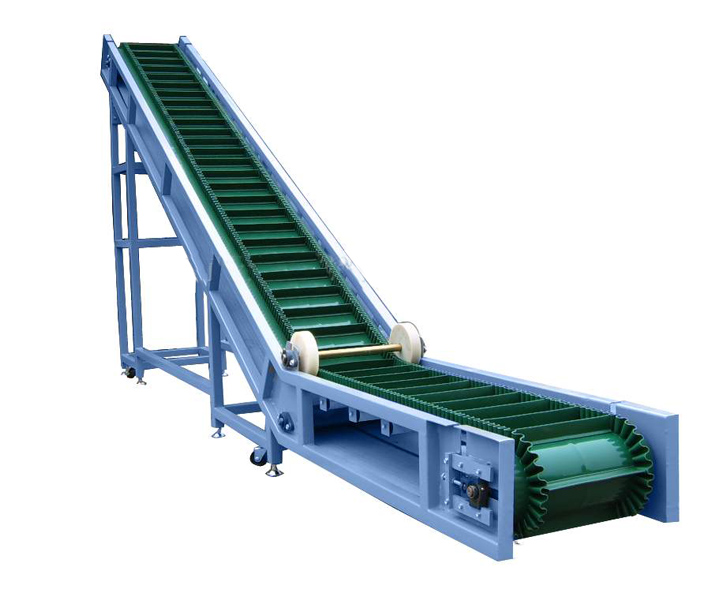

Mobile belt conveyor Horizontal mobile belt conveyor

Horizontal mobile belt conveyor Mobile sidewall belt conveyor

Mobile sidewall belt conveyor Mobile climbing belt conveyor

Mobile climbing belt conveyor Inclined mobile belt conveyor

Inclined mobile belt conveyor

Used for the transportation, stacking, loading and unloading of bulk grain and packaged grain, and is mainly used in places where the loading and unloading location frequently changes.

![]()

![]()

![]()

Price:$800.00-$5,000.00/Set

Consult now and enjoy a 10% discount

Belt width: 400/500/650/600/800/1000/1200/1500mm

Conveying capacity: 70-278m³/h

Conveying length: 10-15 meters

Conveying speed: 1.25-2.0 m/s

Application: It is used in places where the loading and unloading locations change frequently, such as coal yards, warehouses, construction sites, sand and gravel yards, farms, etc., for short-distance transportation and loading and unloading of bulk materials or finished items with a single weight of less than 100 kg.

Commitment:

Mobile belt conveyor is composed of frame, walking wheel, universal wheel, and lifting device, which is easy to move. It is suitable for transportation, stacking, loading and unloading of bulk grain and packaged grain, and is mainly used in places where loading and unloading locations frequently change. The mobile belt conveyor can also be equipped with hydraulic cylinders and power units, which can adjust the height, reducing the danger and work intensity caused by manual lifting, and can adjust the height of the mobile belt conveyor to 3 meters (10 feet) and the height of the stacker. Adjusted to 6 meters (20 feet). Can be manufactured in standard lengths or according to customer requirements.

The mobile belt conveyor can move freely and flexibly, a cost-effective and flexible way, because they can move quickly and easily transported from one job site to another, they can be forward, backward, variable speed and serial connection, Can be used for various applications.

Mobile liftable belt conveyor: The height of the lifting and lowering can be adjusted according to the height of the silo or truck. It is often used for short-distance transportation of bulk materials or finished items. The mobile lifting belt conveyor is generally equipped with two pneumatic tires and two universal wheels, which are flexible and convenient to move. Other models can also be customized according to the special needs of users.

Mobile retractable belt conveyor: also known as mobile loading conveyor, which can be freely expanded and contracted in the length direction, and the length of the conveyor can be controlled at any time. It can convey materials in two directions, and can be used in conjunction with other conveying equipment and material sorting systems to realize automatic production of materials in and out of storage or vehicle loading and unloading.

Mobile belt conveyors are suitable for various industries and scenarios that require portable and flexible material handling. Here are some common applications for moving belt conveyors:

Construction Sites: Widely used on construction sites for efficient material handling. They can transport aggregates, sand, cement and other construction materials to different areas of the site, such as mixing plants, storage areas, or directly into trucks for transport.

Mining and Quarrying: Used in mining and quarrying operations to transport bulk materials such as coal, ore, gravel and aggregates. They can be easily relocated to different areas of the mine or quarry for efficient material movement, loading and unloading of truck or rail cars, and storage.

Agriculture: For tasks such as loading and unloading crops, grain, seeds and fertilizers. They enable farmers to efficiently move materials around the farm, for example from storage bins to trucks or directly into processing equipment.

Warehousing and logistics: Can be used to load and unload trucks, move goods between different areas of the warehouse, or connect various processing or packaging equipment to improve the efficiency of inventory management and order fulfillment.

Ports and terminals: Used for loading and unloading cargo onto ships or barges. They can be easily maneuvered to different berths or locations, enabling efficient and flexible material transfer during loading and unloading operations.

Mobile belt conveyor for conveying sand

Mobile liftable belt conveyor for conveying wood chips

Easy to move

A moving wheel is installed at the bottom, which can be moved at will according to the stacking position of the material, and can be pushed in and out of the warehouse manually. It is mainly used for occasions where the loading and unloading places change.

Height adjustable

Equipped with hydraulic lifting device, the height of its end can be controlled at any time, its processing efficiency can reach 30 pieces per minute, and the lifting height can reach 6 meters.

Large delivery volume

It can be designed to be conveyed downward according to the conveying direction of the user, and can be used for unloading. It is generally used when unloading bagged materials, and the conveying capacity is 160 tons/hour.

Horizontal/inclined conveying

It can be transported by a single machine according to the requirements of the transportation process. Multiple belt conveyors are composed of other conveyors or combined into a horizontal or inclined conveyor system.

One machine for multiple purposes

The conveyor has two speeds, fast and slow, to adapt to different requirements for bulk transportation and packaging, which improves the utilization of equipment and gives full play to the multi-purpose performance of one machine.

Customizable

Belts of different widths can be provided according to the user's conveying volume, and guide grooves and baffles can also be installed at the rear of the fuselage to prevent materials from slipping.

Mobile belt conveyor is a flexible conveying equipment that usually consists of a support structure, a conveyor belt, a transmission device and an electric motor. Its working principle is that it is driven by an electric motor, and the transmission device transmits power to the conveyor belt to make it run continuously. The support structure supports the conveyor belt so that it remains stable during the work process.

Fixed belt conveyor: It means that the whole set of equipment is fixed in one place and cannot be moved. It is mainly used in fixed conveying occasions, such as special docks, warehouse goods movement, transportation between factory production processes, raw material receiving and finished product release.

Mobile belt conveyor: refers to a complete set of equipment installed on wheels, which can be moved. It has the characteristics of strong mobility and high utilization rate, and can arrange transportation operations in time to meet the loading and unloading requirements. The conveying capacity of this kind of equipment is not too large, and the conveying distance is not long, which is suitable for small and medium-sized warehouses.

| Model | Belt Width (mm) | Lenth(m) | Belt Speed (m/s) | Lifting Height | Slope Angle | Capacity (m³/h) |

| DY-500 | 500 | Max.20 | 0.8-2.0 | adjustable | 0-30 | 50-140 |

| DY-650 | 650 | Max.20 | 0.8-2.0 | adjustable | 0-30 | 100-250 |

| DY-800 | 800 | Max.25 | 0.8-2.0 | adjustable | 0-30 | 170-350 |

| DY-1000 | 1000 | Max.25 | 0.8-2.0 | adjustable | 0-30 | 270-550 |

Notes:The parameter above is just for reference,More models pls inquiry us directly.We accept customization.

1. Specifications: 5 meters, 8 meters, 10 meters, 12 meters, 15 meters, 18 meters, 20 meters and other specifications.

2. Belt: belt width can be 500mm, 600mm, 650mm, 700mm, 800mm, 1000mm, 1200mm....

3. Belt thickness: 8mm, 10mm, 12mm, 14mm.....Use high-quality EP belts.

4. Frame: high-strength carbon steel

5. Running speed: It can be controlled from 0.3m/s-2.5m/s, and the mobile belt conveyor can control the running speed to meet the different requirements of bulk transportation and packaging,

6. The height of the upper and lower motors can be adjusted, and the operation is very convenient.

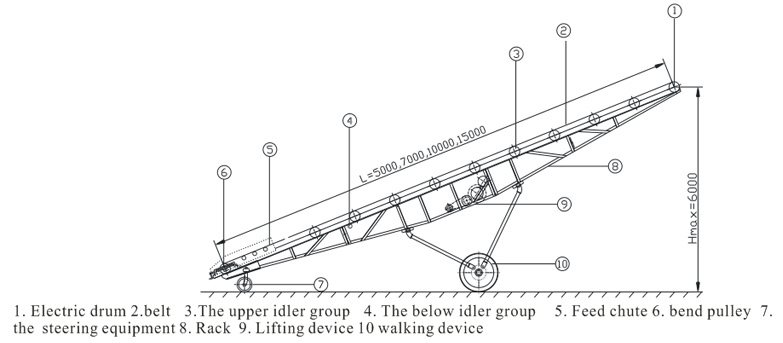

Mobile belt conveyor is mainly composed of solid tires, casters, driving devices, conveyor belts, idlers, tensioning devices, rollers and redirecting devices.

1. Walking wheels: There are two types of pneumatic tires and steel wheels.

2. Driving part: It is composed of the electric motor installed on the base welded by the section steel --> high-speed coupling --> reducer --> reduction coupling.

According to the layout requirements: the drive device is equipped with two types: left-mounted and right-mounted, and the company is equipped with oil-cooled electric drums with a power of 1.5KW to 13KW and a speed of 0.80, 1.0, and 1.25.

3. Rolling part: It is divided into two categories: driving roller and reversing roller.

4. Idler part: slotted, parallel, self-aligning and buffer idler, etc.

5. Cleaning part: divided into spring cleaner and empty section cleaner.

6. Unloading part: divided into fixed plough unloader and electric unloader.

7. Braking part: there are two types of belt backstop and roller backstop.

8. Accessories: in the cover, guide trough, funnel, etc.

Application in the logistics industry

It can be started and stopped with one key, and the fixed type can be seen at the entrance of the logistics express warehouse. With the progress of the box truck, it can be extended slowly and freely, and the manual operation is convenient, which can save a lot of manual operation; not only can it be suitable for 7.8 meters carriage, but also The use of 12-meter container is welcomed by foreign trade export units.

Application in the grain industry

It is used for short-distance transportation and loading and unloading operations in the grain industry. The storage belt and retractable belt device are added, which can be freely stretched in the length direction, and the length of the conveyor can be controlled at any time. It is usually used in grain loading and unloading industries.

Application in the fertilizer industry

Through it, the fertilizer can be transported from the initial feeding point to the unloading point, and it can cooperate with the technological process in the production process of the enterprise to improve the production efficiency of the enterprise.

The mobile belt conveyor produced by Dahan manufacturers adopts belt conveying, which has good wear resistance and can support 24-hour non-stop material transportation of the equipment; it adopts hard surface gears, which has strong material bearing capacity, and is 2-3 of the soft surface mask wheels. It is suitable for conveying bulk materials and finished items under 100 catties. Our Dahan manufacturers have guaranteed product quality and excellent materials, so users can rest assured in terms of performance.

The mobile belt conveyors produced by our factory mainly include various models such as 400mm, 500mm, 650mm in width, the lifting height can reach 1.8m, the length can reach 15m, and the conveying capacity of materials is large; the mobile belt conveyor casing designed and produced by our factory can Downward conveying, and the output can reach 160t/h; in addition, our factory can accept customer's "tailor-made" equipment to meet the user's material screening needs to the greatest extent, according to the customer's production origin, equipment size, conveying height, Conveying length, conveying throughput, etc., create exclusive mobile belt conveyors for customers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.