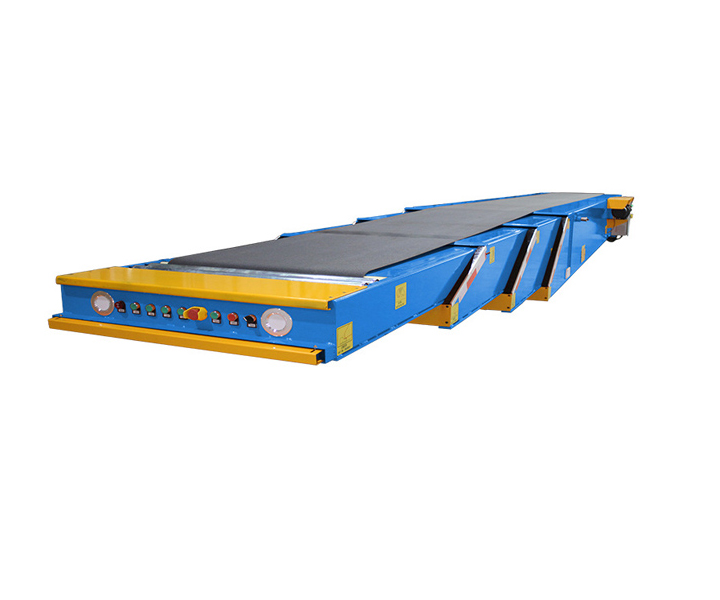

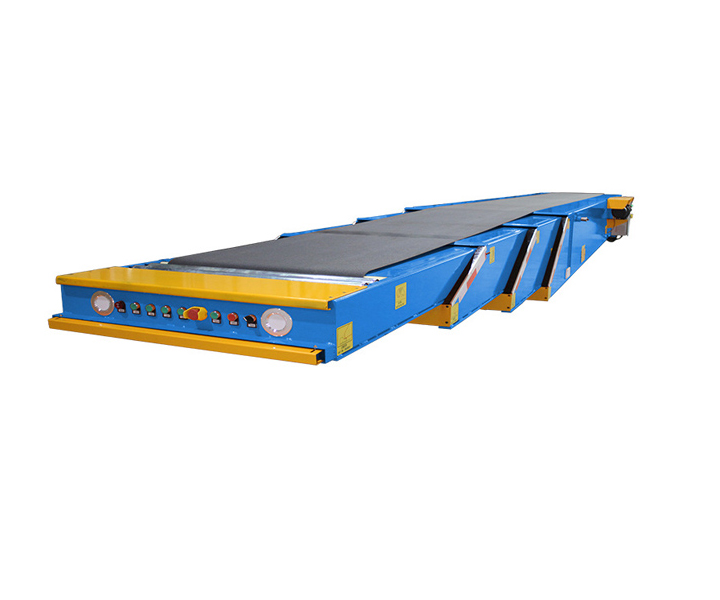

The telescoping feature allows the conveyor to be adjusted to different lengths, making it a versatile and flexible solution for a variety of applications.

![]()

![]()

Price:$900.00-$5,400.00/Set

Consult now and enjoy a 10% discount

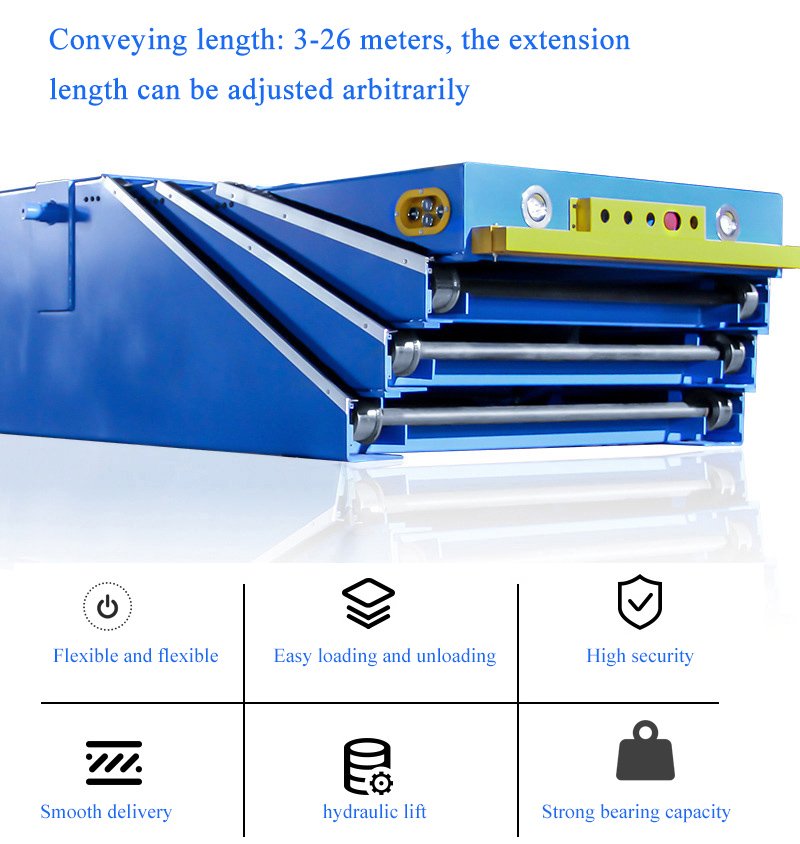

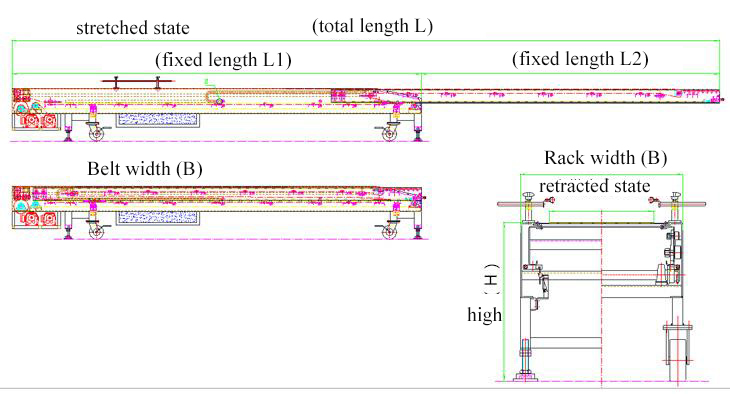

Belt width: 400-1200mm

Fixed length: 3-26 meters

Extended length: 2.8-14 meters (can be customized)

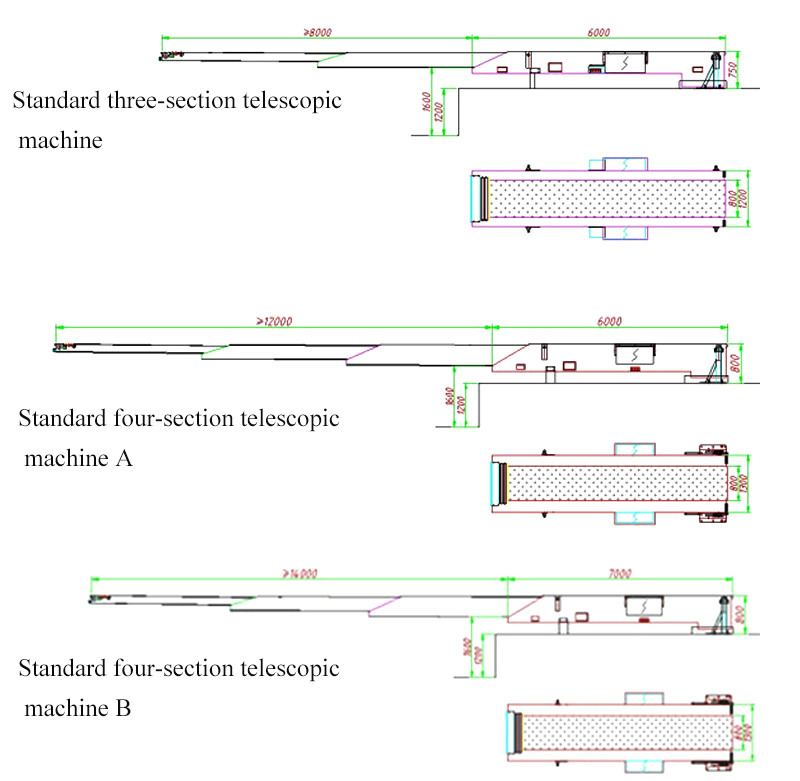

Number of conveyor sections: two-section, three-section, four-section

Capacity: 50-400T/H

Power: 8.5KW-18KW (depending on the length)

Application: Typically used in warehouses, distribution centers and shipping facilities for loading and unloading trucks and containers. They are also used in manufacturing plants and assembly lines to transport materials to different workstations.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

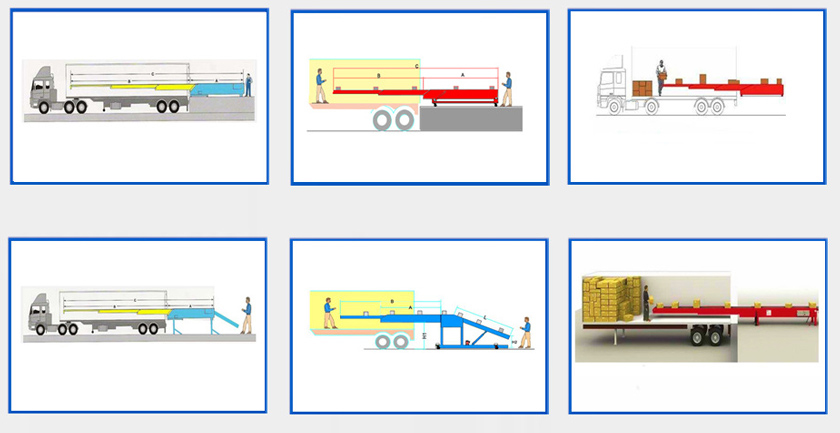

Telescopic belt conveyor, also known as telescopic loader, adds a belt storage device and a retractable belt device. It can be freely stretched in the length direction through an operation lever or operation button. When loading and unloading trucks, the conveyor belt can be extended all the way. To the front end of the truck trailer, making the process of loading and unloading goods faster, easier and safer, it can be freely extended and retracted in the length direction through an operation lever or operation button, and the length of the conveyor can be controlled at any time. Easy and efficient loading and unloading of goods.

Compared with ordinary belt conveyors, the transport of goods on telescopic belt conveyors uses a height-adjustable jack-up platform, which helps make the operation smoother when extending and retracting the conveyor, reducing the physical burden and the risk of injury to employees .

| Features | Telescopic belt conveyor | Ordinary belt conveyor |

| Length | Adjustable | Fixed |

| Flexibility | High | Low |

| Application scenarios | Applied to logistics, warehousing, production lines and other fields, especially suitable for occasions where the conveying distance needs to be adjusted frequently, such as automobile manufacturing, electronic assembly, etc. | Mainly used for fixed conveyor lines, such as mines, ports, food processing and other industries |

| Complexity | High | Low |

| Cost | High | Low |

| Function | Adjustable length, strong flexibility, wide adaptability | - |

Number of conveyor sections: two-section, three-section, four-section. Conveyor belt width: 500, 600, 700, 800, 1000, 1200mm. The telescopic belt conveying speed can be selected: fixed speed or variable speed. Belt conveying direction can be selected: one-way or two-way conveying materials. Belt conveying inclination can be selected: horizontal, fixed inclination or automatic lifting. The base of the fixed section of the conveyor can be selected: fixed or mobile. Conveying speed: <30m/min. Conveyor carrying capacity: <70kg/m.

| Type | section | Fixed Length (A) | Extension length (B) | Total Length (C) | Belt Length (W) |

| DH-2-6A/4B | 2 | 6000 | 4000 | 10000 | 600/800 |

| DH-3-5A/7B | 3 | 5000 | 7000 | 12000 | 600/800 |

| DH-3-6A/8.6B | 3 | 6000 | 8600 | 14600 | 600/800 |

| DH-4-5A/10B | 4 | 5000 | 10000 | 15000 | 600/800 |

| DH-4-6A/12.6B | 4 | 6000 | 12600 | 18600 | 600/800 |

The conveyor belts (or wire ropes) are connected into a closed ring, and they are tensioned by a tensioning device. Under the drive of the motor, the friction between the conveyor belt (or wire rope) and the driving roller (or driving wheel) makes the conveyor belt The belt (or wire rope) runs continuously, so as to achieve the purpose of transporting the load from the loading end to the unloading end.

Improve efficiency

Designed to move goods quickly and efficiently, helping to increase productivity and reduce handling time. They are versatile and can be adjusted to different lengths for a wide range of applications.

Improve security

Helps reduce the risk of injury associated with manual material handling because workers do not have to lift heavy loads. They are also equipped with safety features such as emergency stop buttons and safety barriers.

Reduce labor costs

Helps reduce labor costs because fewer workers are needed to move goods and materials. This helps improve profitability and lower operating expenses.

Easy to operate

Features simple controls for extending or retracting the conveyor. They can also be integrated with other material handling systems, such as automated storage and retrieval systems, to further increase efficiency.

Save space

The compact and space-saving design is especially beneficial for facilities with limited floor space. They store easily when not in use, freeing up valuable space in your facility.

Firmness

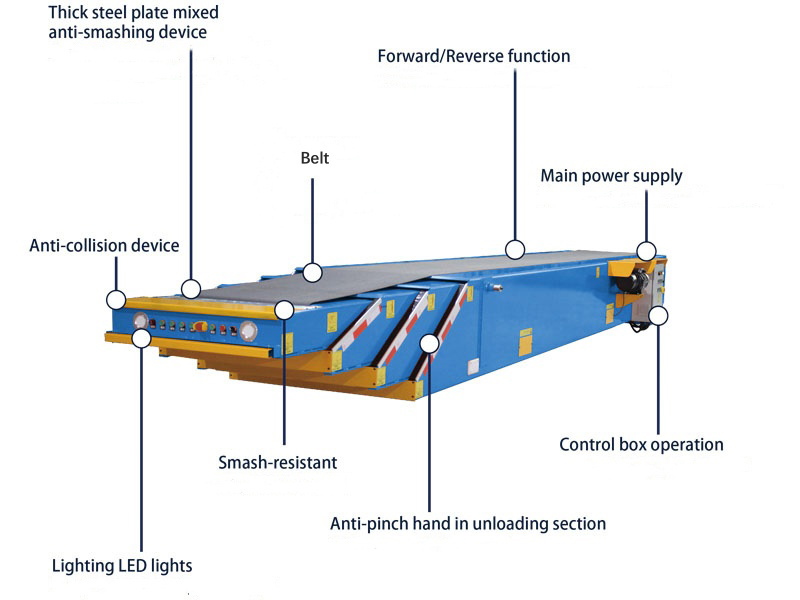

The frame is directly bent by the whole steel plate, and the web parts on both sides are connected by bolts, which can avoid welding deformation and improve installation accuracy.

Telescopic belt conveyor is mainly composed of head drive device, retractable belt device, intermediate frame, feeding device, unloading device and other parts.

Machine head transmission equipment: It is composed of transmission drum, reducer, hydraulic coupling, frame, unloading drum and cleaner.

Intermediate frame: It is a quick and detachable support without bolts, and is composed of H-shaped bracket, steel pipe, flat idler, hook-type grooved idler, "V" type idler, etc.

Belt retracting equipment: located at the back of the tension winch, it is composed of frame, self-aligning idler, reducer, motor, rotating rod, etc.

Feeding equipment and unloading equipment: The feeding equipment is installed behind the receiving and unloading equipment, and is directed from the steering to the feeding section. The conveyed materials are loaded and transported from this section to the unloading section. The rollers unload the material.

Telescopic belt conveyor section number: two-section, three-section, four-section. Width of conveyor belt: 500, 600, 700, 800, 1000, 1200mm.

Conveying speed can be selected: fixed speed or variable speed.

The direction can be selected: one-way or two-way conveying materials.

The inclination angle can be selected: horizontal, fixed inclination or automatic lifting.

The base of the fixed section of the conveyor can be selected: fixed or mobile.

Conveying speed: <30m/min.

Conveyor capacity: <70kg/m.

Telescopic belt conveyor can be easily adjusted to different lengths, making it an invaluable tool for increasing the efficiency and productivity of material handling operations. , the following are its common applications:

Warehousing and distribution: for loading and unloading trucks and containers. They can extend inside trailers or containers, making it easier and more efficient to get in and out of cargo.

Manufacturing and Assembly: Transportation of materials to different workstations. They can be easily adjusted to different lengths, making them a versatile and flexible solution for various production processes.

E-Commerce and Retail: Moving goods and packages from one location to another. They can be used to transport items from warehouses to packing stations, or to load packages onto delivery trucks.

Ports and shipping: for loading and unloading containers. They can extend inside the container, making it easier to move cargo in and out.

Package Delivery: Moving packages from one location to another. They can be used to transport packages from sortation facilities to delivery trucks, or to load packages onto delivery vehicles.

WhatsApp:+86 15236742901

Address::China,Yanjin county forest park gate to the west 1000 meters north road.