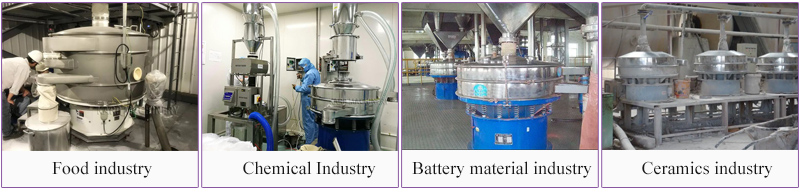

Teflon vibrating screen is treated with Teflon spraying, which has the characteristics of acid and alkali resistance, wear resistance, high temperature resistance, anti-static, etc., and the materials that need to be screened by the vibrating screen have various properties, so the characteristics of this teflon vibrating screen can be aimed at Most of the coatings that are not easy to screen can be better for strong corrosive damage to the vibrating screen, and can also prevent the vibrating screen screen and screen frame from being frequently damaged due to the nature of the material, improve production efficiency and prolong the service life of the vibrating screen. , has been widely used in chemical industry, ceramics, silicon carbide, medicine, food and other industries.

Teflon vibrating screen has the characteristics of acid and alkali resistance, corrosion resistance, wear resistance, high temperature resistance, etc. It can isolate the contact between materials and equipment materials, and effectively avoid secondary pollution of materials.

1. The application of Teflon in the chemical, pharmaceutical, and industrial industries can solve the corrosion and wear of chemical and pharmaceutical equipment, and also ensure that the equipment works normally under high temperature conditions.

2. In the food industry. Teflon also has a good solution to the stickiness of food, and it is non-toxic, so it can be safely used in food.

3. In the ceramic industry, the mud and glaze often have acidic substances, and Teflon has acid and alkali resistance, which can effectively prevent the material from contacting the stainless steel of the screen body, causing the screen body to corrode.

4. Teflon is neither lipophilic nor hydrophilic, it is not easy to be soaked by the solution during production, and it is easy to clean.

1. Isolate the contact between materials and equipment materials, protect the vibrating screen from chemical erosion, and effectively avoid secondary pollution of materials.

2. Non-stick properties or anti-stick properties, easy to clean (almost all substances will not be structured with Teflon coating.

3. It is oil- and water-resistant, and does not pollute the internal materials of the equipment. If there is a small amount of dirt on the surface of the Teflon coating, simply wipe it.

4. The film is cured at a high temperature of 400 degrees Celsius and has excellent heat resistance and low temperature resistance. The vibrating screen coated with Teflon can withstand a high temperature of 300 degrees Celsius for a short time. In general, Teflon coating can be used continuously at 240℃-260℃ without melting.

5. The friction coefficient is very low, only 0.05-0.15.

Teflon vibrating screen consists of bottom barrel, vertical vibration motor, vibration damping spring, screen frame, screen mesh, ultrasonic deblinding system, and dust cover. The equipment is composed of ultrasonic resonance power supply, oscillator and resonance ring. The high-frequency electrical oscillations generated by the ultrasonic resonant power supply are converted into longitudinal oscillation waves in the form of high-frequency sine by the oscillator. These oscillation waves are transmitted to the resonant ring to resonate the resonant ring, and then the resonant ring transmits the vibration evenly to the screen surface. The materials on the net are subjected to low-frequency three-dimensional vibration and superimposed with ultrasonic vibration, which can not only prevent the mesh from clogging, but also improve the screening output.

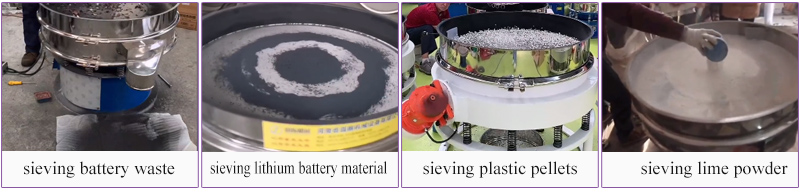

Teflon vibrating screen for sieving graphite powder

Teflon vibrating screen for sieving plastic pellets

| Model |

Screen Diameter (mm) |

Sieving Area (m2) |

Screen Size (mesh) |

Layers |

Power (KW) |

| DHC-400 | 340 | 0.091 | 80-600 | 1~3 | 0.18 |

| DHC-600 | 540 | 0.229 | 0.25 | ||

| DHC-800 | 730 | 0.418 | 0.55 | ||

| DHC-1000 | 900 | 0.636 | 0.75 | ||

| DHC-1200 | 1100 | 0.95 | 1.1 | ||

| DHC-1500 | 1400 | 1.539 | 1.5 | ||

| DHC-1800 | 1700 | 2.269 | 2.2 | ||

| DHC-2000 | 1886 | 2.792 | 2.2 |

Teflon vibrating screen is used in chemical industry, ceramics, silicon carbide, medicine, and food operations. It can be used for most of the coatings that are difficult to screen. It can be better for strong corrosive damage to the vibrating screen, and it can also prevent damage to the vibrating screen due to the nature of the material. The screen mesh and screen frame of the vibrating screen are often damaged, which improves the production efficiency and prolongs the service life of the vibrating screen.

1) Chemicals: resins, coatings, pharmaceuticals, industry, cosmetics, oils, herbal powders, etc.

2) Food industry: sugar, monosodium glutamate, salt, fruit juice, starch, milk powder, food, soy milk, egg powder, rice, soybean, fish meal, pineapple juice, etc.

3) Metal and metallurgical mines: aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, abrasive powder, refractory material, kaolin, lime, alumina, quartz sand, etc.

4) Other industries: waste oil, waste water, waste water dyeing, papermaking, chemical industry, activated carbon, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.