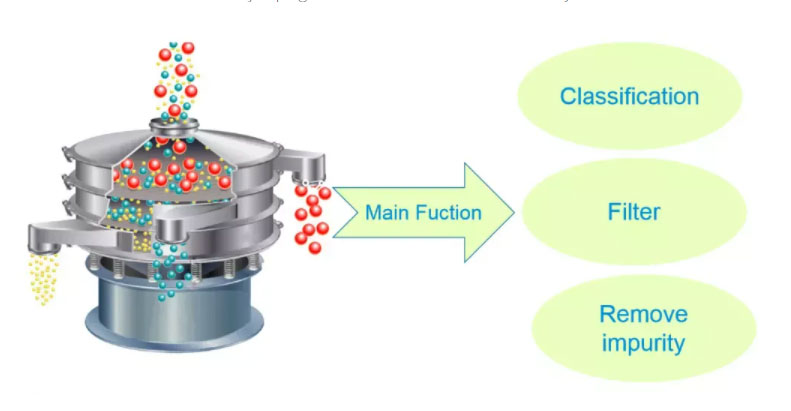

Pollen Vibro Sifter is a kind of mechanical equipment commonly used in pollen particle grading. It separates pollen of different particle sizes through sieve vibration, so as to achieve the effect of classification.

Pollen Vibro Sifter when grading dry pollen, it is first necessary to add the pollen sample to the sieve, and then open the vibrating sieve for sieving. Through the tiny pores of different pore sizes in the sieve, pollen with similar particle sizes within a certain range can be classified into one category to form a genus. Larger pollen particles are sieved onto the upper sieve screen, while smaller pollen particles fall through the sieve holes into the lower collection pan. This completes the isolation and fractionation of the pollen sample.

Wet pollen grains generally require sieving after further processing in solution. The processed wet pollen sample contains a lot of water, which can cause the pollen grains to stick to each other, making it difficult to sieve through the mesh. Therefore, before processing the wet pollen particles, it is necessary to use chemical agents or ultrasonic treatment to disperse the pollen particles and reduce the adhesion phenomenon. Then, the processed wet pollen samples were added to the sieve for vibration sieving. Wet pollen particles with different particle sizes can be classified into different species through the difference in sieve size.

The classification effect of the pollen vibrating screen depends on the separation efficiency and separation precision. Separation efficiency refers to the ratio of the target sample size obtained by the screening process to the original sample size, and separation accuracy refers to the measure of the similarity between different types of pollen samples. If the sieve hole is too large, smaller pollen particles may be missed and cannot be effectively separated; if the sieve hole is too small, pollen particles may stick to the sieve hole and cannot pass through, and the sieving speed will also be reduced.

Therefore, before vibrating pollen sieving, it is necessary to make reasonable selection and optimization according to the characteristics of the sample and the size of the sieve hole to achieve the best grading effect. At the same time, different pretreatment methods are required for different types of pollen (such as dry pollen and wet flower fraction) to obtain effective separation results.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.