The ultrasonic vibrating screen is different from the ordinary vibrating motor as the vibration source. Its advantage is that the screening mesh is high and can be used for extremely fine screening operations.

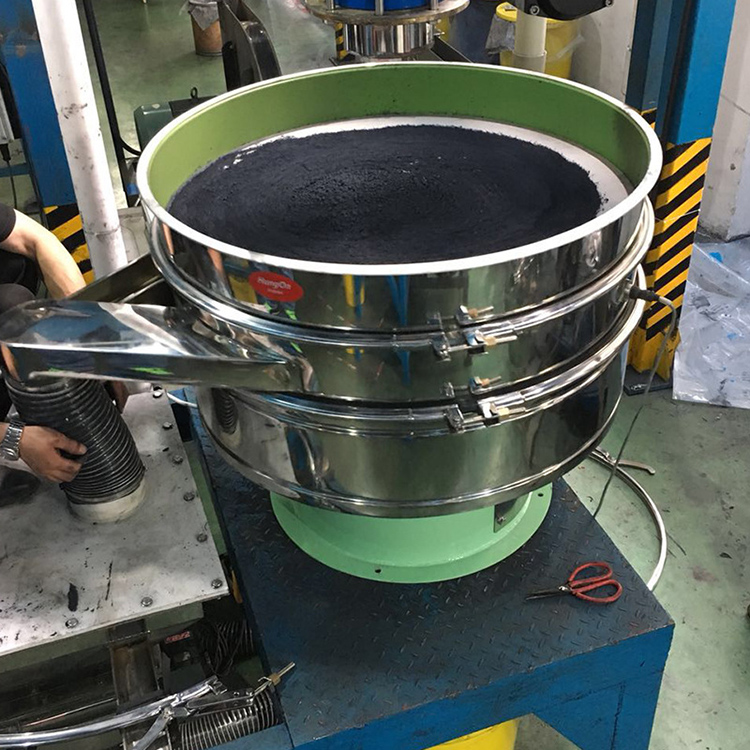

Battery powder refers to the magnetic metal raw materials such as lead, nickel, lithium, etc. and magnetic non-metallic materials contained in the battery. The battery powder cannot be separated from the vibrating screen during the whole process of processing. The battery powder vibrating screen is the For the screening equipment of these powders, since these materials are all powder-type materials, the type of vibrating screen generally used is an ultrasonic vibrating screen.

In the production and preparation of lithium battery materials, ultrasonic vibrating screen is mainly used for the process of crushing materials and before packaging of finished products. It is a kind of equipment used to classify and remove impurities of lithium battery powder. Screen works.

1. Using ultrasonic frequency to vibrate the grid, when sieving lithium battery powder, the sieve hole will not be blocked due to the powder's light weight, high viscosity and high static electricity, and the sieving accuracy is as low as 20μm (635 mesh).

2. An iron remover is installed at the feeding port. During the feeding process, the lithium battery powder first passes through the iron removal silo, and the magnetic bar in it will absorb the iron filings in the material to realize the removal of the iron filings.

3. The sealed structure can eliminate dust pollution and improve the working environment of operators.

4. Both single-layer and multi-layer can work, and one operation can complete the classification of 2-6 levels.

5. Eliminate mesh damage usually associated with mechanical cleaning equipment, prolong mesh life and reduce costs.

Sieve lithium manganate

Sieving lithium iron phosphate

Ultrasonic vibrating screen is an ultrasonic system installed on the ordinary vibrating screen, so that the ultra-fine powder can receive huge ultrasonic acceleration, which solves the problems of adhesion, friction, leveling, wedge and wedge when the ordinary vibrating screen is sieving the ultra-fine powder. Into the other blocking factors, improve the screening efficiency and cleaning efficiency.

Since the above materials have certain magnetic and electrical conductivity, the safety during screening is very important, because these materials belong to the second-level water-burning items, and the water here includes not only clear water, but also moisture in the air. , In addition, these materials are relatively fine and easy to float in the air. Under the influence of moisture in the air, hydrogen will be produced. Hydrogen is a flammable material. At this time, if it encounters a fire source, it will explode and burn instantly. At this time, it is recommended to install an explosion-proof vibration motor for the ultrasonic vibrating screen.

For more detailed information, please contact Dahan Machinery.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.