Self-flowing loading and gravity unloading

![]()

![]()

Price:$500.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Product specification: TD160-400

Belt Type: Rubber Belt or Reinforced Belt

Particle size: 4-180 mm

Production capacity: 0.65-69.6m³/h

Lifting height: 40 meters

Temperature can reach 200°C

Equipment material: carbon steel, stainless steel

Application range: chemical industry, metallurgy, building materials, mining and other industries

Application materials: limestone, calcium carbonate, dolomite, barite, talc, gypsum, diabase, quartz stone, bentonite, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Belt type bucket elevator is a series of hoppers evenly fixed on the endless belt. It is a continuous conveying machine for vertical lifting of materials. It is suitable for lifting from low to high. After the supplied materials are put into the hopper through the vibrating table, the machine automatically runs continuously and transports upwards. For vertical transportation of various industries such as fertilizers, potash and salt, cement, sand and gravel and other materials.

The choice of bucket elevator belt material depends on several factors such as the type of material being transported, the operating conditions, and the specific requirements of the application. Here are some common materials used for bucket elevator belts:

1. Rubber: Rubber belts are commonly used in bucket elevators as they are durable, flexible, and have good abrasion resistance. They can also be designed to have anti-static properties, making them suitable for handling materials that are prone to static buildup.

2. PVC: PVC belts are lightweight and have good chemical resistance, making them suitable for handling materials that are corrosive or abrasive. They are also easy to clean, making them suitable for applications where hygiene is important.

3. Polyester: Polyester belts are strong and have good resistance to stretch, making them suitable for handling heavy loads. They are also resistant to heat and moisture, making them suitable for applications in harsh environments.

4. Nylon: Nylon belts are strong, flexible, and have good resistance to abrasion. They are also resistant to heat and moisture, making them suitable for applications in harsh environments.

5. Steel: Steel belts are used in bucket elevators that handle heavy loads and operate at high temperatures. They are strong, durable, and have good resistance to abrasion and corrosion.

The bucket scoops up the material from the storage below, lifts it to the top with the conveyor belt or chain, goes around the top wheel and turns down, and the bucket elevator dumps the material into the receiving trough. The drive belt of the belt-driven bucket elevator generally adopts a rubber belt, which is installed on the lower or upper driving drum and the upper and lower redirecting drums.

High capacity

Can handle large quantities of material, making it ideal for applications requiring high volumes.

Versatility

Can handle a wide range of materials, including fine powders, granules and large particles.

Customizable

Belt bucket elevators can be customized to meet specific requirements such as height, capacity and material handling characteristics.

Energy saving

Belt-type bucket elevators use less energy than other types of material handling equipment, making them a cost-effective choice.

Low maintenance

Belt-type bucket elevators require minimal maintenance, reducing downtime and maintenance costs.

Safety

The belt type bucket elevator is designed with safety functions such as protective devices, sensors, and emergency stops to ensure safe operation.

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

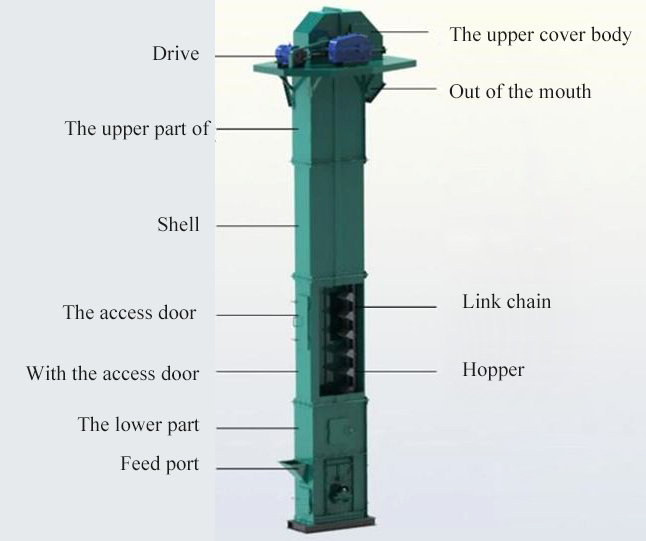

Belt type bucket elevator consists of drive device, upper section, hopper and rubber belt, middle shell, middle shell with access door, lower section, etc. Its main structural features are:

1. The rubber belt is used as the traction member, which has the characteristics of small self-weight, good flexibility, stable operation and low wear and tear.

2. There are sealing devices between the shells and between the inspection door and the shell to ensure no dust leakage, clean and environmentally friendly

3. The casing and the hood are provided with multiple access doors, which can be easily repaired or replaced in the event of failure or the need to replace the wearing parts such as the hopper.

4. There is a high-reliability backstop mechanism inside the traditional device, which prevents the traction element and the loading hopper from running backwards, and makes the overall structure of the transmission device compact and takes up less space.

5. The middle shell is welded by bending components. While improving the overall rigidity of the shell, each section of the shell has good versatility and interchangeability, ensuring that after the assembly is completed, the shell has a good vertical Spend

6. There is a tensioning mechanism at the bottom to ensure that the belt has sufficient pre-tightening force during operation; at the same time, there is an automatic centering mechanism in the bottom roller device to prevent the roller from tilting after being subjected to uneven tension, thereby causing equipment failure.

ssBelt bucket elevators can be customized with several options to suit specific material handling requirements and operating conditions. Here are some common options available for belt bucket elevators:

1. Bucket Type: Buckets can be customized in terms of size, shape, and material to suit specific material handling requirements. Buckets can be made of materials such as plastic, steel, or stainless steel.

2. Belt Type: Belt type can be customized based on the material being handled, the operating conditions, and the specific requirements of the application. Belt types include rubber, PVC, polyester, nylon, or steel.

3. Bucket Attachments: Bucket attachments such as lip extensions, wear strips, and bolt-on cutting edges can be added to improve the performance and durability of the buckets.

4. Belt Attachments: Belt attachments such as cleats, sidewalls, and V-guides can be added to the belt to improve the handling of specific materials.

5. Discharge Options: Discharge options such as rotary valves, slide gates, and diverters can be added to control the flow and discharge of the material.

6. Dust Control: Dust control options such as dust collectors, vented buckets, and enclosed conveyors can be added to reduce dust and protect the environment.

7. Monitoring and Control: Monitoring and control options such as sensors, alarms, and automation systems can be added to monitor the performance of the elevator and ensure safe and efficient operation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.