Stainless steel filter sieve

Stainless steel filter sieve Stainless steel 450 vibration filter

Stainless steel 450 vibration filter Stainless steel liquid 450 filter sieve

Stainless steel liquid 450 filter sieve 450 type stainless steel filter sieve

450 type stainless steel filter sieve Stainless steel 450 vibration filter sieve

Stainless steel 450 vibration filter sieve

SS 304 or 316L stainless steel for food industry, clean and hygienic, can eliminate and suspend unwanted particles present in the material

![]()

![]()

![]()

Price:$420.00-$600.00/Set

Consult now and enjoy a 10% discount

Function: Eliminates or separates all unwanted suspended solids present in liquid products.

Screen size: 25 microns

Processing capacity: 120m3/hour

Material: 304/316L stainless steel

Voltage: 220v/380v

Power:0.18KW

Application materials: coating, ink, color paste, paint, latex paint, aluminum powder paste, soybean milk, fruit juice, beverage, mud, pulp, waste liquid, Chinese and Western medicine liquid, etc.

Stainless steel filter sieve is made of SUS304 or 316L stainless steel, mirror-polished, and the internal and external surface finish is 0.1-0.2 RA. It is specially used for removing large particles and suspended solids in powder or liquid in food, medicine, and chemical industries. Stainless steel filter sieve generally adopts a single layer, adopts large-diameter discharge, and discharges quickly. It is suitable for filtering materials with less impurity content within 400 meshes, good fluidity, and low output requirements, such as soybean milk, flour, paint, latex paint, Juice etc.

304 stainless steel filter sieve: widely used, it has the characteristics of anti-oxidation, anti-corrosion, easy to clean, and can prevent product pollution.

316L stainless steel filter sieve: Type 316 stainless steel is added molybdenum element on the basis of 304 stainless steel. Compared with 304 stainless steel, it has better corrosion resistance. Therefore, 316L stainless steel screw conveyor is durable and avoids excessive metal pollution. It is mostly used in Under strong acid and strong alkali environment.

| 304 and 316 stainless steel comparison | ||||

| Serial number comparison item | Contrast | 304 | 316L | Remark |

| 1 | Price | Low | High | 304 stainless steel has excellent performance, low unit price, and is more widely used |

| 2 | Molybdenum content % | 0 | 2-3 | The higher the Mo content, the better the corrosion resistance and heat resistance. |

| 3 | Nickel content % | 8-10.5 | 10-14 | The higher the Ni content, the better the corrosion resistance and heat resistance. |

| 4 | Carbon content % | <0.08 | 0.03 | The higher the c content, the harder the city ② the lower the c content, the better the welding performance |

| Notes |

1: When we refer to 316 stainless steel, we mean 316L stainless steel 2: Carbon is a strong austenite forming element, which can significantly improve the strength of steel, but the higher the carbon content in carbon steel, the worse the plasticity, and carbon also has an adverse effect on corrosion resistance |

|||

Stainless steel filter sieve is made of 304 stainless steel or 316L stainless steel, which is clean, hygienic, easy to clean, corrosion-resistant, high-temperature resistant, and meets the hygienic standards of the food and pharmaceutical industries. It can sieve or filter flour, soybean milk, fruit juice, mature vinegar, syrup, paint, etc. Less impurity, low output powder, liquid material.

Application in the paint industry: There are impurities in the paint liquid, the paint liquid is too thick, and the quality of latex paint is poor, resulting in uneven wall coating. During construction, brands with good leveling properties should be used. Before the last coat of topcoat, the paint liquid should be Use after filtering.

Application in the food industry: Juice production companies need to filter the juice before canning to filter out the large particles of pulp inside to improve the taste. Soymilk manufacturers need to install a stainless steel filter sieve with any sieve between 80-140 mesh to filter to improve the taste. Both hot and cold soymilk can be used!

Application in chemical industry: quickly separate and remove impurities for small chemical dry powder or slurry materials to improve product purity.

Filter nail powder

Filter soy milk

304 stainless steel material

The machine is made of stainless steel (304), which is more conducive to the filtration and removal of impurities of the liquid, and the slag discharge is smooth.

Operational safety

The motor with waterproof grade IP54 + anti-seepage water treatment, the slurry does not leak, which can prevent the damage of the motor caused by the liquid.

Prevent the slurry splash

The screen grid heightened design, large observation port, easy to observe the screen surface, prevent the slurry from splashing, and the liquid does not leak.

Automatic cleaning

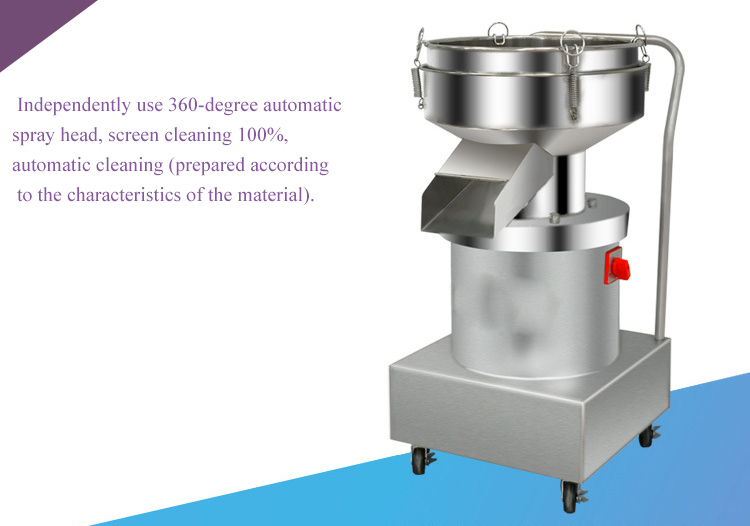

Independent 360-degree automatic spray head, 100% screen cleaning, automatic cleaning (prepared according to the characteristics of the material).

| Model | DH-450 | DH-450S (With moving wheels) |

| Overall size (mm) |

500*500*600 | 500*500*1000 |

| Screen body size (diameter * height) (mm) |

488*135 | 488*135 |

| weight (Kg) |

40 | 48 |

| Power (Kw) |

0.18 | 0.18 |

| Support customized production(Click here to get accurate quotation) | ||

Stainless steel filter sieve can be specially customized according to the needs, such as trolley type, mobile type, heightened screen frame type, valve type, dust cover (fully sealed type), heightened bottom bucket type, etc., various models Complete specifications.

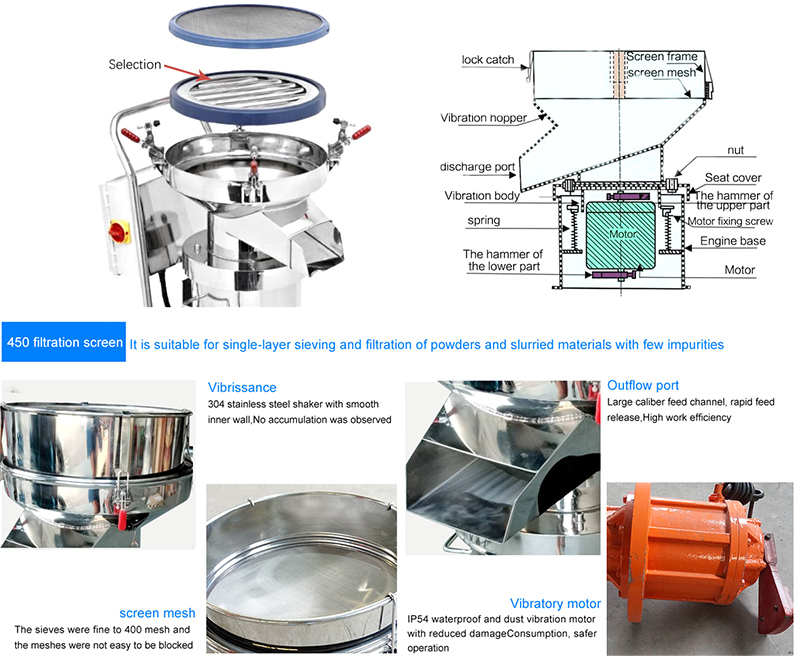

Stainless steel filter sieve is mainly composed of screen frame, screen mesh, machine base, vertical vibration motor, etc. Generally, the parts in contact with materials are made of 304 stainless steel, the machine base is ordinary carbon steel, the weight of the whole machine is about 42 kg, and the horizontal vibration The motor is installed inside the machine base, at the lower part of the screen frame and the screen. The diameter of the screen frame is 450mm. The single-layer screen has no wear and long service life compared with the mother screen and the screen is directly pressed on the screen frame. In the tank, the screen is installed tightly, the screening and filtration efficiency is high, and the screen is easy to change.

| Material | Mesh | Capacity |

| Spray paint | 325 mesh | 1200L/h |

| Flour | 30 mesh | 700kg/hour |

| Juice | 40-80 mesh | 6-10 cubic meters/hour |

| Soy milk | 100-200 mesh | 1200kg/hour |

| Pigment | 100-200 mesh | 500kg/hour |

Xinxiang Dahan stainless steel filter sieve manufacturer is a manufacturer specializing in the production, sales and service of material filtration, screening and impurity removal equipment. The manufacturers have passed ISO9001 quality system certification and ISO/CE certification, and have successfully served more than 80 countries around the world.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.