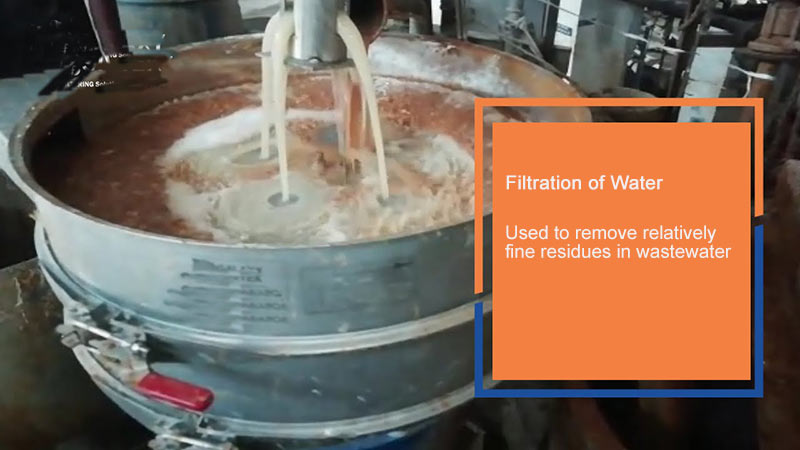

Water sieve filter can effectively remove domestic garbage, heavy metal particles and finer particle pollutants in sewage. Under the action of vibration force, the liquid in the suspended matter passes through the pores of the medium, and the solid particles are intercepted and reach the effect of solid-liquid separation.

Water sieve filter is suitable for high-flow liquid treatment, quickly removes large particles with small content, quickly removes insoluble solids in various slurries, and removes unqualified impurities from slurries. The following is an example of the application of water sieve filter in related sewage treatment:

1. Mineral dressing industry: The industrial wastewater of the mineral dressing industry contains many heavy metal particles. The application of sieve filter has effectively removed the heavy metal particles in the sewage and greatly improved the utilization rate of resources.

2. Papermaking industry: sieve filter plays the role of filter grid in the pretreatment of industrial wastewater generated in the papermaking industry, effectively removing large particle pollutants in wastewater.

3. Domestic sewage: With the improvement of the quality of life, the discharge of domestic sewage is also increasing. There are a lot of domestic garbage in the domestic sewage, and sieve filter has been well applied in the pretreatment of these domestic waste.

4. Sewage treatment plant: The treatment of sewage in sewage treatment plants must go through pretreatment-secondary treatment-advanced treatment and other links. Just now we mentioned that sieve filter can play the role of filter grid in pretreatment, and then we can also use filter The fine filtration before sedimentation makes the sedimentation time greatly shortened, and also makes the energy efficiency of sewage treatment more efficient.

1. Stainless steel (304) material, which is more conducive to liquid filtration and impurity removal;

2. Waterproof IP54 motor + anti-seepage water treatment, safer operation, and can prevent damage to the motor caused by liquid;

3. The heightened design of the screen grid prevents the slurry from splashing, and the large observation port makes it easy to observe the screen surface;

4. Independent use of 360-degree automatic spray washing head, screen cleaning 100%, automatic cleaning (prepared according to the characteristics of the material);

5. Special inlet and outlet gates make the cloth more uniform and higher precision.

Water sieve filter is mainly composed of screen frame, screen, frame, vertical vibration motor, etc. Generally, the parts that contact the material are made of 304 stainless steel, and the frame is made of plain carbon steel. The weight of the whole machine is about 42 kg. Horizontal vibration motor Installed inside the machine base, located at the lower part of the screen frame and the screen. The screen frame diameter is 450mm. The single-layer screen is non-wearing and has a long service life compared with the mother-child screen. The screen is directly pressed on the screen frame. In the tank, the screen is installed tightly, the screening and filtering efficiency is high, and the screen is easy to change.

The two sets of eccentric blocks (unbalanced eccentric blocks) at the upper and lower ends of the vibration motor shaft convert the rotation movement of the vibration motor into horizontal, vertical, and

Inclination and centrifugal action are often used to overlap, and then this force is transmitted to the screen surface. Changing the phase angle and weight of the upper and lower eccentric blocks can change the size of the exciting force and the movement track of the material, so as to achieve the purpose of particle powder screening.

| Model | Power (kW) |

Whole machine size (mm) |

Sieve body size(Diameter*Height) (mm) |

Weight (kG) |

Description |

| DH-450 | 0.18 | 500*500*600 | 488*135 | 40 | The seat material is Q235 high quality carbon steel, stainless steel can be selected according to needs |

| DH-450s (With mobile trolley) |

500*500*1000 | 48 |

| Product | Proportion | Mesh size | Method | Capacity (kg/hr t/hr) |

| Pig feces | 1.1 | 120 mesh | wet | 20000t |

| Waste water | 1-1.3 | 60 mesh | 15000t | |

| Dyeing and steaming wastewater | 1 | 150 mesh | 22000t | |

| Waste oil | 0.9 | 100 mesh | 3800t |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.