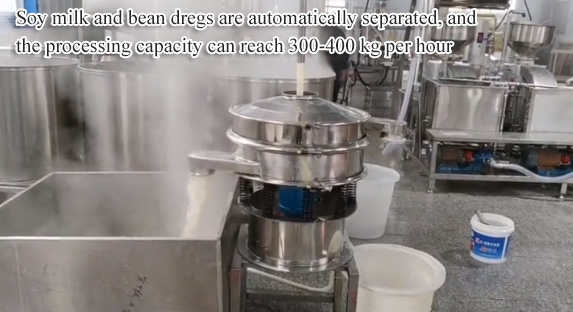

Soymilk filter can be used in the filtration and impurity removal of soymilk, which is much more efficient than traditional soymilk filtration, and the soymilk filter is a layer with two outlets. After being separated by a screen, the residue on the screen can be automatically discharged without manual labor Clean, and can be continuous, assembly line operation.

In the whole screening process, the sealing performance is strong, and the liquid does not leak; the discharge port adopts the inclined design, the material is discharged quickly, and there is no retention phenomenon. According to the needs of different customers, a variety of grid structures can be designed and replaced. Screen time is fast.

Soymilk is made by soaking soybeans in water, grinding, filtering, and boiling. Soak the soybeans in water for about 3 to 8 hours, soak the soybeans, then grind the soybeans or use a grinder to form a slurry with bean dregs, and then use a rotary vibrating screen to separate the bean dregs to obtain raw soybean milk. Add raw soy milk and water to a boil for 5 to 10 minutes before serving. Raw soy milk must be boiled completely to destroy soya saponin, which can trigger allergies. The soy milk before cooking and packaging can also be filtered again with a rotary vibrating sieve to ensure that a small amount of bean dregs or other impurities are mixed into the soy milk.

In the case that the user has no special requirements, it is generally enough to use a layer of soymilk filter with two outlets. When sieving soybean milk, its power device, namely the eccentric blocks at the upper and lower ends of the vibrating motor with different phases, generates a compound inertial force due to the effect of high-speed placement. Under the effect of force, it continuously reciprocates, and then drives the screen surface to vibrate periodically, so that the materials on the screen surface will make directional positive movement together with the screen box, during which, the materials smaller than the aperture of the screen surface will fall to the screen through the screen holes. The lower layer becomes the undersieve, and the material larger than the aperture of the screen surface is discharged from the discharge port after continuous beating movement, and the screening work is finally completed. Thereby separating the impurities of soy milk.

1. Both raw soybean milk and cooked soybean milk can be filtered, which can remove impurities in the soybean milk, and the filtered soybean milk tastes better.

2. The flow rate can be as high as 120m3/hour, impurities can be automatically discharged, and a variety of new mesh frame designs can ensure that the screen is durable and fine materials are filtered to 25 microns (500 mesh).

3. It is made of ss304 or 316L stainless steel specially used in the food industry, which has the characteristics of heat resistance and high temperature resistance, and fully meets the requirements of the food industry.

4. In the existing conditions, the feeding port is enlarged, and it is also equipped with a special angle design to avoid the liquid bursting out, preventing material leakage and material splashing.

5. The special vibrating screen for food is designed with a mother-type and stamping-type mesh frame. It can be changed by 2 people. The mesh number of the filter mesh can be adjusted at any time.

Although the discharge port of the refiner is equipped with a filter screen, which can roughly separate the soybean milk and soybean dregs, it still cannot fully meet the market standards. The original method of using filter cloth to shake and filter manually is very slow, and the output is relatively low. In addition, the labor cost is becoming more and more expensive, which is very uneconomical. It is an economical and cost-effective choice to use soymilk filter instead of traditional manual filtering.The following is a comparison of soymilk filter and other filtering methods:

| Type | 60-120 mesh filtration speed | 140-160 mesh filtration speed | 180-240 mesh filtration speed | Main cost |

| Artificial | Fast | Generally | Slightly slower | Full-time staff salary + consumables |

| Simulate Labor | Generally | Slightly slower | Slow | Full-time staff salary + consumables + high power consumption |

| Roller | Generally | Slightly slower | Slow and easy to spread paste net | Full-time employee salary + consumables + medium power consumption |

| Vibrating Screen | Quick and easy to splash | Generally easy to splash | Slightly slow, easy to splash paste, easy to spread paste net | Semi-full-time employee salary + consumables + medium power consumption |

| Soymilk Filter | Fast and stable | Fast and stable | Fast and stable | Part-time employee salary + consumables + low power consumption |

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

According to the customers in the soybean product preparation industry who visited the Dahan vibrating screen, we learned that according to the different types of soybean products, manufacturers have different requirements on the fineness of the soybean milk liquid in the production process. There are also various requirements for the fineness of For example, to make tofu, the mesh of soymilk filter is required to be around 100-200 mesh, and the mesh of 200-300 mesh is required to make tofu skin, dried tofu and yuba.

In order to help customers spend less money to buy better equipment, especially in view of the different sizes of soy product processing enterprises, Dahan Machinery summarizes the general price determination rules of soymilk filter as follows, hoping that everyone can use the preferential price Buy easy-to-use slurry screening equipment. The price of soybean milk filter can be judged from the following aspects:

1. Equipment width: This series of soymilk filters are generally circular, and the diameter of the circular sieve determines the output, so the diameter of the sieve surface is one of the important criteria for determining its price.

2. Material: The material of the soybean milk filter is 304 stainless steel for material contact. The latter will be slightly more expensive than the former.

3. Manufacturer: The production qualification of a soymilk filter manufacturer is an important criterion for judging the quality of a piece of equipment. Regular manufacturers will design different production plans according to different production requirements of users, so the price of soybean milk vibrating screens produced by regular manufacturers will vary. higher than that of small factories.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.